If you’re into 2JZ engines, you know they’re beasts when it comes to power potential. But with great power comes great heat—and that’s where water/methanol injection steps in like a secret weapon. Imagine your engine running cooler, smoother, and pushing harder without the fear of detonation wrecking your day. That’s exactly what this setup offers. It’s not just about cranking up the boost; it’s about controlling the chaos that comes with it. Water/methanol injection cools down the intake air, reducing the chance of knocking, which means you can safely push your engine further without hesitation. It’s like giving your 2JZ a breath of fresh, icy air right before it hits the combustion chamber.

Think about it—when you slam the throttle, the intake air heats up, and that heat can cause premature combustion, or knock, which is the enemy of any tuner. Water/methanol injection acts like a firefighter, dousing those high temperatures and calming the combustion process. Plus, methanol adds a little extra octane boost, making the fuel burn cleaner and more controlled. This combo lets you squeeze out power gains without frying your engine. It’s not magic, just smart science.

Many 2JZ enthusiasts swear by this method because it’s a simple, effective way to protect their investment while extracting every last bit of performance. Whether you’re running a turbo monster or a high-compression naturally aspirated setup, water/methanol injection provides that extra layer of safety and power. It’s like having a guardian angel watching over your engine, ensuring it runs at peak performance without the risk of catastrophic failure.

In short, water/methanol injection isn’t just an upgrade—it’s a necessity for anyone serious about pushing their 2JZ to the edge. It’s the difference between holding back and going full throttle with confidence. So, if you want your engine to breathe cooler, run cleaner, and last longer while delivering more power, this is the route to take.

What Is Water/Meth Injection and Why Use It on the 2JZ?

Ever wonder how some 2JZ engines seem to run cooler and push out more power without blowing up? The secret often lies in a clever trick called water/methanol injection. At its core, this system sprays a fine mist of water and methanol into the intake air. Sounds simple, right? But the effects are anything but. This spray cools down the intake charge, which means the air entering the engine is denser and cooler—perfect for squeezing more power out of every combustion cycle.

Why does the 2JZ, a legendary engine known for its strength and tuning potential, benefit so much from this? Because when you start cranking up the boost or compression, the risk of detonation (that nasty knocking sound that can destroy engines) goes way up. Water/meth injection acts like a firefighter, quenching the flames of detonation before they get out of control. It’s not just about power; it’s about keeping the engine safe when you push it hard.

Think of it like adding a secret ingredient to a recipe that makes everything better without changing the main flavors. The 2JZ already loves boost, but water/meth injection lets you feed it more boost safely. Plus, methanol itself burns like a high-octane fuel, effectively raising your octane rating and allowing the engine to run more aggressive timing without hesitation.

Many tuners swear by this system because it’s a relatively affordable way to protect their investment while gaining noticeable performance. It’s especially popular in turbocharged setups, where intake air temps can soar and cause headaches. Rather than swapping out expensive intercoolers or risking engine damage, water/meth injection offers a smart, efficient solution.

So, why use water/meth injection on the 2JZ? In short: it’s a simple, effective way to cool intake air, prevent knock, and safely unlock more power. It’s like giving your engine a breath of fresh, icy air right when it needs it most. Without this, pushing the 2JZ beyond its factory limits can be a risky game. With it, you gain control and confidence—two things every tuner wants under the hood.

How It Works: Cooling Intake Temps and Raising Octane

Imagine your 2JZ engine as a beast that loves to breathe cool, dense air. When the intake air heats up, it’s like trying to run a marathon in a sauna—performance tanks, and the risk of knock skyrockets. This is where water/methanol injection steps in, acting like a refreshing splash of cold water on a hot day for your engine.

When you spray a fine mist of water and methanol into the intake air, something pretty cool happens—literally. The water quickly evaporates, absorbing heat and dropping the intake temperature drastically. This cooler air is denser, meaning more oxygen molecules pack into each breath your engine takes. More oxygen means better combustion, which translates to more power on tap.

But the magic doesn’t stop there. Methanol, a type of alcohol, acts like a fuel booster with a twist. It raises the effective octane rating of the air-fuel mix inside the cylinder. Think of octane as the engine’s resistance to premature explosions, or “knock.” Higher octane means the fuel burns smoothly, not too early or too fast, which is crucial when you’re pushing your 2JZ hard with high boost or compression.

Here’s the kicker: the combination of cooling and octane boost lets you safely push your engine beyond its usual limits. Without water/meth injection, you might have to dial back boost or risk damaging knock. With it, you get a safety net that helps prevent detonation, keeps combustion controlled, and lets your 2JZ run stronger and cleaner.

Think of it like this: water/meth injection is the secret weapon that tames the fiery heart of your turbocharged 2JZ. It cools the air, raises octane, and keeps everything in check, allowing you to squeeze out extra power without the fear of catastrophic engine knock. It’s a simple yet effective way to get more from your build while protecting your investment.

Benefits for High-Boost and High-Compression 2JZ Builds

When you push a 2JZ engine to its limits with high boost or increased compression, things get intense quickly. The engine is working harder, hotter, and under more stress than ever before. This is where water/methanol injection steps in as a reliable ally. Think of it as a breath of fresh, cool air for your engine’s combustion chamber. It cools down the intake charge, which means the air entering your engine isn’t scorching hot. Hot air can cause detonation—basically, your fuel-air mix exploding too soon—which is a nightmare for engine health.

By lowering intake temperatures, water/meth injection helps prevent this unwanted knocking. That’s crucial because knock can lead to serious damage fast, especially in high-compression setups where the engine is already primed to ignite the fuel-air mix earlier due to the tighter squeeze. With water/meth injection, you’re buying yourself more time and safety margin. You can run higher boost pressures or increase compression ratios without the constant fear of catastrophic knock.

But it’s not just about protection. There’s a performance boost hidden in this cooling effect. Cooler air is denser air, packed with more oxygen molecules ready to burn fuel efficiently. This means your engine can breathe better, combust cleaner, and ultimately produce more power. It’s like giving your 2JZ a turbocharged ice bath—refreshing and performance-enhancing all at once.

Here’s a quick snapshot of why water/meth injection is a game-changer for aggressive 2JZ builds:

- Detonation control: Reduces knock risk, protecting pistons and valves.

- Increased boost potential: Safely push turbo pressures higher.

- Improved combustion: Denser air means more power and efficiency.

- Lower intake temps: Keeps your engine running cooler under stress.

From personal experience, installing a water/meth system on a turbocharged 2JZ felt like unlocking a hidden level of reliability. The engine ran smoother, and I could dial in more boost without that nerve-wracking pinging noise. It’s not just a gadget—it’s peace of mind for anyone pushing their 2JZ hard. In short, if you’re building a high-boost or high-compression 2JZ, water/meth injection isn’t just an option—it’s a smart upgrade that keeps your engine safe and hungry for power.

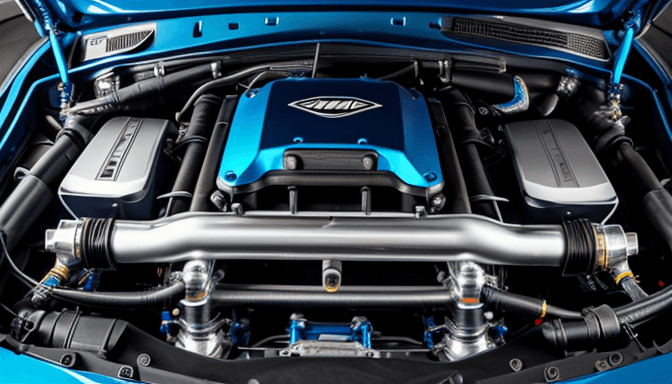

Top Kits for the 2JZ: AEM, Snow Performance, Coolingmist

If you’re diving into the world of water/methanol injection for your 2JZ, picking the right kit can feel like sorting through a maze. Each brand promises the moon, but what really fits your build? Let’s break down the top contenders: AEM, Snow Performance, and Coolingmist. These names keep popping up in forums and builds for a reason—they deliver solid results without the headache.

AEM kits are often the go-to for those who want reliability and simplicity wrapped in one package. Their systems are known for easy installation and solid components that don’t quit. If you’re someone who likes to keep things straightforward but effective, AEM’s injection kits provide consistent spray patterns and reliable flow rates. Plus, their nozzle options give you flexibility whether you’re running a mild or wild setup.

Then there’s Snow Performance, a brand that’s almost synonymous with water/methanol injection in the tuning world. Their kits are praised for their versatility and advanced controller options. What sets Snow apart is their ability to tailor injection volume based on boost pressure, so your 2JZ engine gets just the right amount of cooling and octane boost exactly when it needs it. It’s like having a smart assistant for your engine, dialing things in on the fly.

Not to be overlooked, Coolingmist offers some of the most robust and customizable kits out there. If you’re building a high-boost monster or pushing your compression limits, Coolingmist’s systems provide precise control and durable hardware that stands up to harsh conditions. Their direct port options are especially popular for those who want pinpoint accuracy in injection placement, which can make a noticeable difference in knock prevention.

Here’s a quick look at how these kits stack up:

| Feature | AEM | Snow Performance | Coolingmist |

|---|---|---|---|

| Installation Ease | Simple, user-friendly | Moderate, requires tuning | Complex, for advanced users |

| Controller Type | Basic to advanced options | Smart, boost-based modulation | Highly customizable |

| Injection Style | Single nozzle or direct port | Single nozzle with modulating flow | Direct port favored |

| Best For | Street builds and mild boosts | Street and track with variable boost | High-boost, race-level setups |

Choosing between these kits comes down to your goals and how hands-on you want to be. If you want something that just works out of the box, AEM is a solid bet. If you’re chasing that perfect balance of automation and control, Snow Performance has you covered. And if you’re building a serious beast and want every drop of precision, Coolingmist is worth the extra effort.

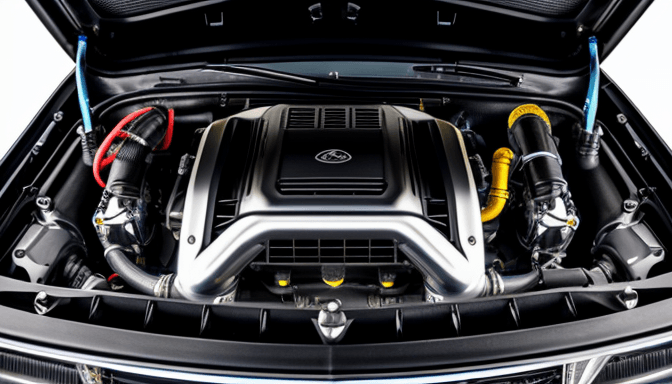

Direct Port vs Single Nozzle Systems: Which to Choose

When it comes to choosing between direct port and single nozzle water/methanol injection systems for your 2JZ, the decision isn’t just about picking a side—it’s about matching the system to your engine’s needs and your goals. Think of it like choosing between a precision scalpel and a broad paintbrush. Both have their place, but their impact is very different.

Direct port systems spray water/methanol right into each intake runner, giving you precise control over the cooling and octane boost for every cylinder. This means you get a more even distribution, which is crucial if your 2JZ is pushing some serious boost or running high compression. It’s like giving each cylinder its own personalized cooling drink—no one gets left thirsty. This method reduces the chance of hot spots and detonation, making your engine safer and more consistent under heavy load. But here’s the catch: direct port setups are more complex to install and tune. They require careful placement of multiple nozzles and a bit more wiring wizardry. So, if you love tinkering and want the best possible control, this might be your go-to.

On the flip side, single nozzle systems spray a mist of water/methanol into the intake tract before it splits off to the cylinders. It’s simpler, easier to install, and usually less expensive. Imagine it as spraying a fine mist into a room rather than handing out individual glasses of water. It works well for moderate boost levels and street builds where simplicity and reliability are key. The trade-off? You may not get perfectly even distribution, and under extreme conditions, some cylinders might not get as much cooling, which could lead to uneven combustion or slight knock.

So, how do you decide? Here’s a quick rundown:

| Feature | Direct Port | Single Nozzle |

|---|---|---|

| Installation Complexity | High | Low |

| Cost | Higher | Lower |

| Cooling Precision | Excellent | Good |

| Best For | High-boost, high-compression builds | Moderate boost, street builds |

Ultimately, it’s about matching the injection style to your build’s demands. If you’re pushing the limits and want every ounce of control, direct port is worth the extra effort. But if you’re cruising with moderate boost and want a straightforward setup, single nozzle systems deliver solid results without the headache.

Remember, both systems can make a big difference. It’s not just about spraying water and methanol—it’s about how effectively that spray cools your intake air and keeps your 2JZ running smooth and safe. Choose wisely, and your engine will thank you with power and peace of mind.

Installation Tips for the 2JZ Intake and Electrical Setup

When it comes to installing a water/methanol injection system on your 2JZ, the details matter more than you might think. This isn’t just about slapping a nozzle somewhere and calling it a day. The intake placement and electrical wiring can make or break the performance and reliability of your setup. Imagine trying to cool down a hot summer day with a tiny fan in the wrong spot — it just won’t work as effectively. The same principle applies here.

First off, the intake nozzle placement is crucial. You want the injection to happen where the intake air is flowing fast and is well-mixed — usually right before the throttle body or inside the intake manifold runners. This ensures the water/methanol mix atomizes properly, cooling the air charge evenly. If you spray too far upstream, the droplets might settle or evaporate unevenly, which reduces the cooling effect and can cause inconsistent combustion. Think of it like watering a garden: you want the water to hit the roots, not just the surface.

Next, the electrical setup demands careful attention. Your injection system relies on precise signals to activate at the right time — typically triggered by boost pressure or throttle position. Running the wiring through a clean, protected path away from heat sources and moving parts is essential. Nothing kills a good setup faster than a loose connection or a wire melting under the hood. A good tip is to use heat-resistant sleeving and secure your cables with zip ties or clamps to avoid vibration damage. It might sound obvious, but taking the extra time here saves headaches down the road.

Another important aspect is integrating the system with your ECU or boost controller. Some setups require a dedicated controller, while others can tap into existing signals. Either way, make sure your wiring and sensors are compatible and calibrated properly. Incorrect signals can cause the injection to misfire or not activate when needed, defeating the whole purpose. It’s like having a fire extinguisher that only works half the time — not exactly comforting.

Lastly, don’t forget to test everything thoroughly before hitting the road or track. A simple dry run without fuel or methanol can help you catch leaks, electrical shorts, or timing issues. Pay attention to how the system reacts under different boost levels and throttle inputs. This hands-on approach is the best way to ensure your 2JZ runs cooler, safer, and stronger with water/methanol injection.

How to Tune Your ECU for Water/Meth Injection

Tuning your ECU to work seamlessly with water/methanol injection isn’t just a nice-to-have—it’s a must if you want to squeeze every bit of performance while keeping your 2JZ engine safe. Think of it like adjusting the sails on a boat; without the right tweaks, you won’t catch the wind properly, and your ride could get rough.

First off, the main goal here is to recalibrate your engine’s timing and fuel delivery. Water/methanol injection cools the intake charge and raises the effective octane, which means your engine can handle more aggressive timing without knocking. But if your ECU isn’t tuned to recognize this, you might miss out on power gains or, worse, cause damage.

Start by dialing back your ignition timing slightly before activating the injection system, then gradually advance it as you monitor knock sensors and engine response. This step is crucial because it lets you find that sweet spot where your engine runs *clean* and *efficient* with the injection helping to prevent detonation.

Fuel mapping also needs attention. Water/methanol injection can lean out your air-fuel mixture if the ECU isn’t compensating. You’ll want to enrich the fuel slightly during injection events to maintain the right balance. Many tuners use wideband O2 sensors and dataloggers here to keep an eye on AFR (air-fuel ratio) in real-time. It’s a bit like tuning a guitar—you adjust the strings (fuel and timing) until the sound (engine performance) is just right.

One common mistake is leaving the ECU unaware of when the injection kicks in. Using a dedicated input from the water/methanol system to trigger timing and fueling changes can make a huge difference. Some advanced ECUs allow you to program injection events directly, making the process smoother and more precise.

Remember, every 2JZ build is unique. Your tuning approach depends on boost levels, compression ratios, and the specific water/methanol setup you’re running. Patience is key here. Don’t rush the process—tuning is an art as much as it is a science. Test, log, adjust, and repeat.

In short, tuning your ECU for water/methanol injection means embracing a dynamic dance between timing and fueling, guided by real-world data and a keen ear for your engine’s needs. When done right, you’ll enjoy a safer, stronger, and more responsive 2JZ that takes full advantage of what water/methanol injection brings to the table.

Common Myths and Mistakes with Methanol Injection

Methanol injection often gets a bad rap, but a lot of that comes from myths that just won’t quit. One big misconception? That it’s some kind of magic bullet that instantly boosts power without any downsides. That’s far from the truth. Sure, it helps cool intake temps and reduce knock, but it’s not a free pass to crank boost without proper tuning or setup. Think of it like a safety net, not a turbocharger replacement.

Another common mistake is assuming you can just pour methanol straight into your system and forget about it. In reality, maintenance and correct mixture ratios are crucial. Using the wrong blend—or worse, running pure methanol without the right precautions—can lead to corrosion or even engine damage. It’s not just about dumping fluid; it’s about balance and care.

People also tend to overlook the importance of proper installation. Installing methanol injection without considering nozzle placement or wiring can cause inconsistent spray patterns or system failures. If the spray doesn’t hit the right spot in the intake, it won’t cool the air effectively, and you might still face detonation issues. It’s like watering a garden but missing half the plants.

Then there’s the myth that methanol injection eliminates the need for careful ECU tuning. Nope. Without adjusting ignition timing and fuel maps, you’re flying blind. The engine might run lean or rich, risking damage or poor performance. Tuning is the secret sauce that makes the system work smoothly and safely.

Lastly, many underestimate the risks of methanol’s flammability and toxicity. Handling it carelessly can cause health hazards or fire risks. Always store and use methanol in well-ventilated areas and follow safety guidelines. It’s powerful stuff, but with respect and knowledge, it’s a valuable tool for your 2JZ build.

In short, methanol injection isn’t a “set it and forget it” upgrade. It demands respect, proper setup, and ongoing attention. When done right, it’s a fantastic way to protect your engine and squeeze out extra power. When done wrong? Well, that’s when the problems start.

Using 50/50 vs 100% Methanol Mixtures Safely

When it comes to water/methanol injection for your 2JZ engine, choosing between a 50/50 blend and 100% methanol isn’t just about numbers—it’s about safety and performance in real-world conditions. The 50/50 mix, which combines water and methanol equally, is often favored because it cools intake air effectively while offering a smoother, safer injection. Think of it like a gentle breeze cooling you down on a hot day—enough to refresh without overwhelming. This blend reduces the risk of lean conditions and helps prevent detonation, making it ideal for most street-driven or moderately boosted 2JZ setups.

On the flip side, 100% methanol packs a punch. It’s like switching from that breeze to a gust of wind—powerful, but you better be ready for it. Pure methanol delivers more aggressive cooling and a higher octane boost, which can be a boon for high-boost or racing applications. However, this comes with a catch: methanol is highly corrosive and demands careful handling and system maintenance. Running 100% methanol requires precise tuning and robust components to avoid damage and ensure reliability. It’s not a “set it and forget it” scenario.

Here’s the kicker: safety and longevity hinge on understanding your build’s needs and how each mixture interacts with your engine. For example, if you’re pushing your 2JZ with big turbo upgrades and high compression, 100% methanol might give you the edge you need—but only if you’re prepared to monitor your system closely. Conversely, a 50/50 blend offers a forgiving balance, especially if you’re new to water/methanol injection or want a dependable, low-maintenance setup.

To put it simply, choosing the right mixture is like picking the right tool for the job. Neither is inherently better; it’s about matching your injection strategy to your engine’s demands and your comfort level with maintenance. Remember, methanol’s corrosive nature means you’ll want to use compatible materials for your injectors and lines, regardless of the mix. Neglecting this can lead to costly repairs and downtime.

In the end, whether you go for 50/50 or 100% methanol, the key is to stay informed and cautious. Keep an eye on your fuel trims, listen for knock, and never skip regular system checks. That way, your 2JZ will thank you with smooth power delivery and fewer headaches down the road.

Frequently Asked Questions

- What exactly is water/methanol injection, and why is it popular for 2JZ engines?Water/methanol injection is like giving your 2JZ engine a refreshing splash of coolness right when it needs it most. By spraying a mix of water and methanol into the intake air, it drastically lowers intake temperatures and raises the effective octane rating. This combo helps prevent detonation and knock, which means you can safely push your engine harder without fearing damage. That’s why it’s a go-to upgrade for anyone wanting to boost power and reliability in their 2JZ setup.

- How does water/methanol injection actually reduce intake air temperature?Think of it as a mini air conditioner for your engine’s intake. When the water/methanol mix is injected, it absorbs heat as it evaporates, cooling the intake air significantly. Cooler air is denser, packing more oxygen into each cylinder, which improves combustion efficiency. Plus, methanol acts as a fuel with a high octane rating, helping to prevent those nasty pre-ignition events that can wreck your engine.

- Can I use water/methanol injection on any 2JZ engine, or is it only for high-boost setups?While water/methanol injection really shines in high-boost or high-compression 2JZ builds, it’s not limited to just those. Even moderate builds can benefit from cooler intake temps and knock prevention. However, the bigger the boost or compression, the more critical it becomes to keep detonation in check, making injection systems a smart investment for aggressive tuning.

- What’s the difference between direct port and single nozzle water/methanol injection systems?Direct port systems spray water/methanol directly into each intake runner, offering precise cooling and knock control on a cylinder-by-cylinder basis. Single nozzle systems, on the other hand, spray into the intake tract before the throttle body, which is simpler but less precise. If you’re aiming for maximum performance and fine-tuned control on your 2JZ, direct port is the way to go. For budget builds or simpler installs, a single nozzle might suffice.

- How difficult is it to install a water/methanol injection system on a 2JZ engine?Installing a water/methanol injection kit on a 2JZ isn’t rocket science, but it does require some care. Proper intake placement is key to ensure even distribution, and you’ll need to wire the system correctly to synchronize injection with boost levels. Most kits come with detailed instructions, but if you’re not confident with electrical work or plumbing, consulting a pro can save headaches down the line.

- Do I need to tune my ECU after installing water/methanol injection?Absolutely. Water/methanol injection changes combustion dynamics, so tuning your ECU ensures you’re maximizing benefits without risking lean conditions or other issues. A good tune will adjust ignition timing and fuel delivery to complement the cooling and octane-boosting effects, unlocking safer power gains and smoother performance.

- Is it safer to use a 50/50 water/methanol mix or 100% methanol?Using a 50/50 mix is generally safer and more user-friendly. The water component helps prevent corrosion and reduces methanol’s flammability risk while still providing excellent cooling and octane benefits. Pure methanol packs a bigger punch but requires more careful handling, storage, and system compatibility. Choose based on your comfort level and performance goals.

- Are there any common myths or mistakes I should watch out for with water/methanol injection?One big myth is that water/methanol injection can fix all tuning problems or replace proper engine management—spoiler alert: it can’t. Also, running the system dry or neglecting maintenance can cause damage rather than prevent it. Always monitor fluid levels, maintain your system, and use injection as a tool alongside proper tuning and build quality.