The Toyota 2JZ engine is a legend in the automotive world, celebrated for its unmatched durability, high horsepower potential, and robust design. From the iconic Supra to ambitious swap projects, the 2JZ has earned its place as a favorite among tuners and performance enthusiasts.

However, as enthusiasts push the boundaries of this engine’s capabilities, achieving big horsepower numbers introduces a new challenge: managing the intense heat generated by high-power builds. Proper cooling is no longer a luxury—it’s a necessity. Insufficient cooling can lead to overheating, reduced efficiency, and even catastrophic engine failure.

This article dives into everything you need to know about upgrading your 2JZ cooling system for big power builds. From radiators to oil coolers and supporting modifications, we’ll explore the essential components and strategies needed to keep your engine running cool and performing at its peak. Whether you’re chasing 700 horsepower or looking to exceed 1,000, this guide will provide actionable insights to help you achieve your goals safely and reliably.

Why Cooling Matters for High-Power 2JZ Builds

Pushing a 2JZ engine to its limits requires addressing the heat generated by increased horsepower. In high-performance builds, thermal management is not just about maintaining efficiency—it’s about safeguarding the engine from irreversible damage.

1. Heat Generation in High-Performance Engines

- Turbochargers and Heat: Turbochargers force more air into the engine, generating more power but significantly increasing heat. The compressed air and exhaust gases rapidly elevate temperatures within the engine bay.

- Increased RPMs: High-revving engines produce more friction, leading to greater thermal loads across moving parts like pistons, valves, and bearings.

- Sustained Loads: Track days, drag races, and spirited driving place consistent strain on cooling systems, exposing weaknesses that may not surface during daily driving.

2. The Consequences of Inadequate Cooling

- Performance Drops: Overheating leads to reduced engine efficiency and power output as components struggle to operate under extreme conditions.

- Component Damage: Prolonged exposure to excessive heat can warp the head gasket, damage the pistons, or cause the oil to lose its protective properties.

- Increased Risk of Engine Failure: A compromised cooling system can result in catastrophic failures, such as cracked engine blocks or seized components, leading to costly repairs.

3. What the Competitors Miss

- While many guides touch on the importance of cooling upgrades, they often lack the specificity required for high-power builds. Our guide not only emphasizes the need for radiators, intercoolers, and oil coolers but also provides detailed solutions tailored to 2JZ engines. By covering installation tips, brand recommendations, and supporting modifications, this article fills the gaps left by competitors.

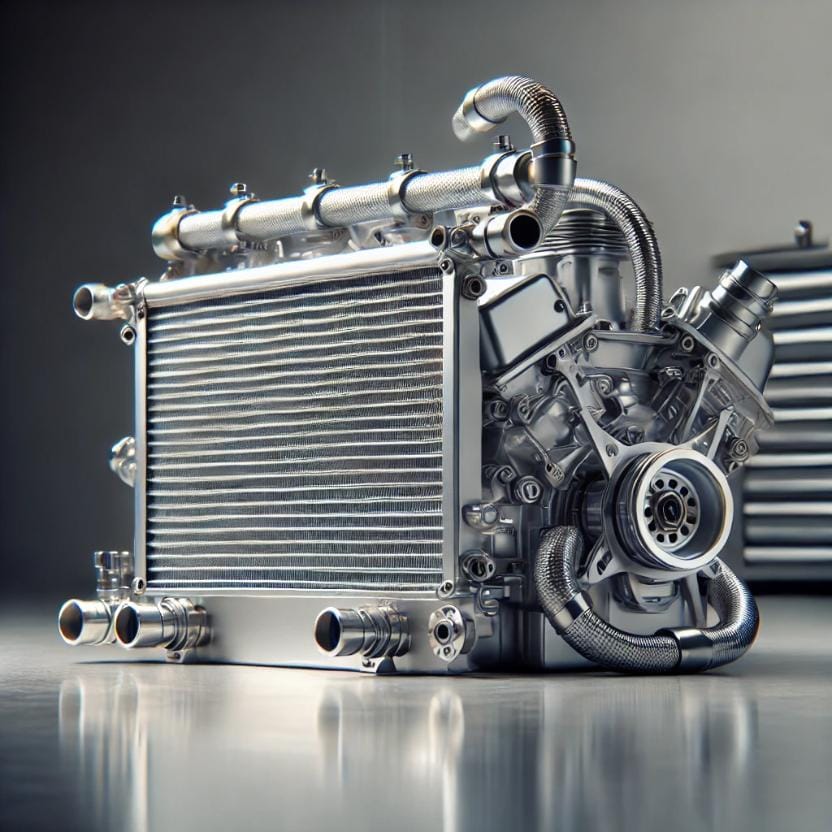

Comprehensive Cooling Upgrades for 2JZ Engines

Cooling a high-power 2JZ engine requires more than just a radiator swap. Each component in the cooling system plays a critical role in managing the increased thermal loads. Here’s a detailed look at the essential upgrades and their importance:

1. Radiators

- The Backbone of Engine Cooling:

- Radiators are the primary heat exchangers in the cooling system. A high-capacity radiator can efficiently dissipate heat generated during high-power runs.

- Key Features to Look For:

- Core Size: Larger cores provide greater surface area for heat dissipation.

- Material: Aluminum radiators are lightweight and offer excellent thermal conductivity.

- Design: Dual-pass and triple-pass radiators improve cooling efficiency by forcing coolant to flow through the core multiple times.

- Top Brands for 2JZ Builds:

- Mishimoto: Known for its durability and performance-oriented designs.

- Koyorad: Offers a range of radiators optimized for 2JZ engines.

- CSF Racing: High-performance radiators with enhanced cooling capacity.

- Installation Tips:

- Ensure there are no air pockets during installation to avoid hot spots.

- Use high-quality silicone hoses for better durability and sealing.

2. Intercoolers

- Critical for Turbocharged Engines:

- Intercoolers cool the compressed air from the turbocharger, reducing intake air temperatures and preventing detonation.

- Air-to-Air vs. Air-to-Water Intercoolers:

- Air-to-Air: More common and effective for street builds. Simpler design with no additional water cooling components.

- Air-to-Water: Ideal for drag racing due to better cooling efficiency in short bursts.

- Recommended Models:

- Precision Turbo Intercoolers: Built for high-boost applications.

- GReddy Intercoolers: Reliable for both street and track use.

- Garrett Intercoolers: Offers robust solutions for extreme builds.

- Upgrade Considerations:

- Match the intercooler size to your power goals to avoid pressure drops.

- Optimize placement for airflow and heat dissipation.

3. Oil Coolers

- Why Oil Temperature Matters:

- As engine oil lubricates and cools moving parts, maintaining its optimal temperature is vital for preventing viscosity breakdown and component wear.

- Types of Oil Coolers:

- Air-Cooled: Relies on airflow to dissipate heat, ideal for most 2JZ setups.

- Water-Cooled: Integrates with the engine’s coolant system, providing superior heat transfer for extreme builds.

- Best Options for 2JZ:

- HKS Oil Coolers: Engineered for high-performance engines.

- Setrab: A favorite among motorsport enthusiasts.

- Powerhouse Racing: Custom solutions tailored for 2JZ engines.

- Installation Tips:

- Use a thermostatic oil cooler adapter to maintain optimal oil temperature during normal driving.

- Avoid long oil lines to minimize pressure loss.

4. Fan Upgrades

- Electric Fans vs. Mechanical Fans:

- Electric Fans: Provide consistent cooling regardless of engine speed. Ideal for high-power builds.

- Mechanical Fans: Depend on engine RPM, often less effective in high-boost applications.

- Top Fan Choices:

- SPAL: Known for high-CFM ratings and reliability.

- Flex-A-Lite: Popular for custom cooling solutions.

Supporting Modifications

Upgrading the primary components of your 2JZ cooling system—such as radiators, intercoolers, and oil coolers—is essential, but the supporting modifications ensure that these upgrades operate at their peak performance. Here’s a breakdown of additional enhancements that elevate your cooling system’s efficiency and reliability.

1. Upgraded Water Pumps

- Why Water Pumps Matter:

- The water pump circulates coolant throughout the engine and radiator. A high-flow water pump ensures consistent coolant flow, which is critical for high-power builds.

- Aftermarket Options:

- Fluidampr: Known for durable and high-performance pumps.

- Power Enterprise: Designed for extreme-duty applications.

- Tips for Optimization:

- Match the pump’s flow rate to the demands of your upgraded cooling components.

- Regularly inspect for leaks and wear, as high-load conditions can stress seals.

2. Thermostats

- Controlling Coolant Flow:

- Thermostats regulate coolant flow based on engine temperature. Upgrading to a lower-temperature thermostat helps keep the engine running cooler in high-performance applications.

- Recommended Models:

- TRD (Toyota Racing Development): Optimized for 2JZ engines.

- Mishimoto Low-Temp Thermostat: Designed for quick response and efficient cooling.

- Installation Note:

- Verify compatibility with your radiator and ensure the thermostat opens at the specified temperature to avoid overheating.

3. Electric Fans

- Improved Cooling Efficiency:

- Electric fans provide consistent airflow across the radiator, independent of engine speed, making them superior to mechanical fans for high-power builds.

- Key Features:

- CFM Rating: Ensure the fan can move enough air to match your engine’s cooling demands.

- Dual-Fan Setups: Ideal for larger radiators or extreme applications.

- Top Brands:

- SPAL: Offers a wide range of high-performance electric fans.

- Derale: Reliable fans with flexible mounting options.

4. Coolant Choices

- Enhancing Thermal Management:

- High-performance coolant formulations reduce the risk of overheating and corrosion while improving heat transfer.

- Best Coolants for High-Power Builds:

- Engine Ice: Non-toxic and ideal for track use.

- Red Line Water Wetter: Enhances heat transfer when mixed with water.

- Usage Tips:

- Avoid mixing coolants with different formulations.

- Regularly flush and replace coolant to maintain system efficiency.

5. Catch Cans

- Protecting Your System:

- A catch can prevents oil vapors and contaminants from entering the intake system, reducing the chances of carbon buildup and maintaining optimal engine temperatures.

- Top Options:

- Radium Engineering: High-quality designs for serious builds.

- Mishimoto Catch Cans: Easy to install and maintain.

6. Heat Management Solutions

- Keeping Engine Bay Temperatures in Check:

- Heat shields and wraps protect critical components from excessive heat.

- Key Products:

- DEI Heat Shields and Wraps: Designed to insulate turbochargers, exhaust manifolds, and downpipes.

- Gold Reflective Tape: Redirects radiant heat away from hoses and wiring.

7. Expansion Tanks

- Maintaining Coolant Levels:

- Expansion tanks provide space for coolant to expand under high temperatures, preventing pressure buildup and leaks.

- Recommended Models:

- Mishimoto Aluminum Expansion Tanks: Durable and aesthetically pleasing.

- Cusco Expansion Tanks: Compact and effective for tight engine bays.

Each of these supporting modifications plays a critical role in ensuring that your upgraded cooling system operates at maximum efficiency. Together, they provide the reliability and thermal management necessary for high-power 2JZ builds.

Installation and Setup

Upgrading your 2JZ cooling system involves more than just purchasing the right components; proper installation and setup are vital to ensuring optimal performance. A poorly installed system can lead to inefficiencies, overheating, or even damage. Below, we provide a comprehensive guide to installing and configuring your cooling upgrades.

1. Professional Installation vs. DIY

- When to Consider a Professional:

- Complex setups involving custom fabrication, such as air-to-water intercoolers.

- If you lack the tools or experience for precise fitment.

- DIY Installation:

- Ideal for straightforward upgrades like radiator replacements or electric fan installations.

- Follow manufacturer instructions carefully to avoid errors.

2. Common Installation Pitfalls

- Air Pockets in the System:

- Issue: Air trapped in the coolant lines can cause hot spots and reduce efficiency.

- Solution: Use a vacuum filler tool or bleed the system thoroughly after filling.

- Improper Hose Fitment:

- Issue: Leaks or restricted flow due to poorly connected hoses.

- Solution: Use high-quality silicone hoses and secure them with proper clamps.

- Overtightened Fittings:

- Issue: Overtightening can crack radiator inlets/outlets or strip threads.

- Solution: Follow torque specifications provided by the manufacturer.

3. Step-by-Step Installation Guide

Radiators

- Drain the existing coolant completely.

- Remove the stock radiator and hoses.

- Install the new radiator, ensuring proper alignment.

- Attach silicone hoses securely and tighten clamps.

- Refill the system with coolant, ensuring no air pockets remain.

Intercoolers

- Mount the intercooler in a position with maximum airflow.

- Route piping with minimal bends to reduce pressure drop.

- Secure the pipes and intercooler with high-quality clamps.

- Check for boost leaks after installation.

Oil Coolers

- Choose a mounting location with good airflow.

- Route the oil lines carefully to avoid sharp bends or contact with hot components.

- Use a thermostatic adapter for temperature control.

- Prime the oil cooler before starting the engine to prevent dry starts.

Electric Fans

- Attach the fan shroud to the radiator using provided brackets.

- Wire the fan to a relay and connect it to a temperature-controlled switch or ECU.

- Test the fan operation before finalizing the wiring.

4. Calibration and Tuning

- Temperature Management:

- Use a standalone ECU or piggyback system to control fan and pump speeds based on engine temperature.

- Coolant Flow Optimization:

- Adjust the thermostat to open at the ideal temperature for your setup.

- Boost Management:

- Fine-tune the intercooler piping and boost controller to ensure efficient airflow without leaks.

5. Final Checks and Testing

- Leak Test:

- Pressurize the system and check all connections for leaks.

- Temperature Monitoring:

- Use a gauge or sensor to monitor coolant, oil, and intake air temperatures during initial runs.

- Break-In Period:

- Gradually push the system to its limits to identify any weak points or issues under load.

6. Documentation and Maintenance

- Keep Records:

- Maintain detailed notes of installed components, torque settings, and maintenance schedules.

- Maintenance Tips:

- Regularly inspect hoses, clamps, and fittings for wear or leaks.

- Replace coolant every 12-24 months or as recommended by the manufacturer.

Proper installation and setup not only ensure the performance of your cooling system but also provide peace of mind for high-power builds. Taking the time to install components correctly will save you from costly repairs down the road.

Maintenance and Monitoring

Once your upgraded 2JZ cooling system is installed, proper maintenance and consistent monitoring are essential to keep it running efficiently and reliably. Neglecting these tasks can compromise performance and even damage critical components in the long run. Here’s a guide to maintaining and monitoring your cooling system for sustained performance.

1. Routine Maintenance

- Coolant Replacement:

- Frequency: Replace coolant every 12-24 months or as recommended by the manufacturer.

- Tips:

- Use high-performance coolants like Engine Ice or Red Line Water Wetter for superior thermal management.

- Flush the system thoroughly to remove old coolant and contaminants before refilling.

- Hose Inspection:

- What to Look For: Cracks, bulges, or soft spots in hoses.

- Replacement Tips:

- Use silicone hoses for durability and better heat resistance.

- Ensure clamps are tight but not overtightened to avoid damaging the hoses.

- Radiator Cleaning:

- Method:

- Clean the radiator fins with compressed air or a soft brush to remove debris.

- Inspect for bent fins and straighten them carefully to maintain airflow.

- Method:

- Oil Cooler Maintenance:

- Check for leaks or damage to the oil lines and fittings.

- Replace the oil cooler’s filter regularly if applicable.

2. Monitoring Tools and Practices

- Temperature Gauges:

- Install digital gauges to monitor:

- Coolant temperature.

- Oil temperature.

- Intake air temperature.

- Set up alerts to warn of rising temperatures beyond safe levels.

- Install digital gauges to monitor:

- Pressure Monitoring:

- Use a radiator cap with a built-in pressure gauge to monitor system pressure.

- Diagnostic Scanners:

- If using an ECU, utilize diagnostic tools to check the performance of electric fans, water pumps, and thermostats.

3. Troubleshooting Common Issues

- Overheating:

- Possible Causes:

- Air pockets in the cooling system.

- Blocked or damaged radiators.

- Insufficient coolant levels.

- Solutions:

- Bleed the system to remove trapped air.

- Flush the radiator to clear blockages.

- Check for leaks and refill coolant as needed.

- Possible Causes:

- Coolant Leaks:

- Common Locations:

- Hose connections.

- Radiator seals.

- Water pump gaskets.

- Solutions:

- Tighten loose clamps.

- Replace worn hoses or seals.

- Common Locations:

- Inconsistent Oil Temperatures:

- Possible Causes:

- Faulty thermostatic adapter.

- Insufficient airflow to the oil cooler.

- Solutions:

- Replace the adapter if malfunctioning.

- Adjust the oil cooler’s mounting location for better airflow.

- Possible Causes:

4. Proactive Upgrades

- Coolant Sensors:

- Upgrade to high-accuracy sensors for real-time monitoring.

- Remote Monitoring Systems:

- Use Wi-Fi or Bluetooth-enabled devices to track temperatures and pressures remotely.

- Data Logging:

- Employ ECU features or standalone logging systems to analyze cooling performance over time.

5. Seasonal Adjustments

- Winter:

- Use coolants with a lower freezing point.

- Avoid running straight water in the cooling system.

- Summer:

- Increase airflow with additional fans or larger radiators if necessary.

- Check all components for heat damage caused by prolonged exposure.

By adhering to a consistent maintenance schedule and utilizing monitoring tools, you can ensure your cooling system operates at peak efficiency, even under extreme conditions. Proactive care not only extends the lifespan of your upgrades but also protects your investment in a high-power 2JZ build.

Case Studies: Real-World High-Power 2JZ Builds

Examining real-world examples provides valuable insights into how cooling upgrades perform under different conditions. Below, we present case studies of 2JZ builds that have successfully implemented high-performance cooling systems.

1. 700 HP Street Build: Optimized for Daily Use

- Owner’s Goals:

- Create a reliable, high-power street car capable of daily driving.

- Maintain temperatures during long drives and occasional spirited runs.

- Cooling System Setup:

- Radiator: Mishimoto dual-pass aluminum radiator.

- Intercooler: Precision Turbo air-to-air intercooler, optimized for reduced pressure drops.

- Oil Cooler: HKS air-cooled oil cooler with a thermostatic adapter.

- Electric Fans: Dual SPAL fans controlled by a standalone ECU.

- Performance Outcomes:

- Stable coolant temperatures of 85°C (185°F) under normal driving conditions.

- Consistent oil temperatures during extended spirited drives.

- Lessons Learned:

- The dual-pass radiator significantly improved cooling efficiency in traffic.

- Proper fan control via the ECU ensured efficient operation during varying loads.

2. 1,000 HP Drag Build: Cooling for Extreme Loads

- Owner’s Goals:

- Maximize horsepower for drag racing while managing extreme thermal demands.

- Ensure reliability during short but high-stress runs.

- Cooling System Setup:

- Radiator: Koyorad triple-pass racing radiator with custom shrouds for maximum airflow.

- Intercooler: Air-to-water intercooler with a dedicated water tank and ice reservoir.

- Oil Cooler: Setrab oil cooler with braided steel lines for durability.

- Auxiliary Cooling:

- DEI heat wrap on exhaust components to reduce engine bay temperatures.

- Mishimoto aluminum expansion tank to manage coolant expansion during high heat.

- Performance Outcomes:

- Coolant temperatures remained stable despite repeated drag runs.

- Intake air temperatures were consistently low due to the ice-cooled intercooler.

- Lessons Learned:

- Air-to-water intercoolers are ideal for short-duration, high-stress applications.

- Heat wraps prevented thermal soak, preserving engine bay components.

3. 850 HP Track Build: Designed for Sustained Loads

- Owner’s Goals:

- Build a high-power track car capable of enduring prolonged sessions.

- Prioritize reliability over peak horsepower.

- Cooling System Setup:

- Radiator: CSF Racing radiator paired with silicone hoses.

- Intercooler: GReddy air-to-air intercooler with a high-flow design.

- Oil Cooler: Powerhouse Racing oil cooler mounted in a high-airflow location.

- Electric Fans: Dual Flex-A-Lite fans with a custom relay system.

- Performance Outcomes:

- Coolant temperatures remained consistent during 20-minute track sessions.

- No oil breakdown or overheating was reported, even on hot summer days.

- Lessons Learned:

- Proper placement of cooling components is critical for airflow.

- Regular system checks between sessions ensured consistent performance.

Key Takeaways from the Case Studies

- Component Selection:

- Matching the right components to the intended use case (street, drag, or track) is crucial.

- Proper Installation and Maintenance:

- Attention to detail during installation, combined with proactive maintenance, prevents system failures.

- Tailored Solutions:

- Custom configurations, such as air-to-water intercoolers or heat wraps, enhance performance in specific scenarios.

These case studies highlight the real-world effectiveness of cooling upgrades for 2JZ engines. Whether you’re building a street car, drag racer, or track beast, applying the lessons learned from these examples can help you achieve reliable performance.

Conclusion

The Toyota 2JZ engine is a powerhouse that has captured the hearts of enthusiasts worldwide. However, as you push its limits to achieve impressive horsepower figures, managing the engine’s thermal demands becomes critical. Proper cooling upgrades are the foundation of a reliable and high-performing build.

Key Takeaways

- Core Components: Radiators, intercoolers, and oil coolers are essential for handling the increased heat from high-power applications.

- Supporting Modifications: Upgraded water pumps, low-temp thermostats, and electric fans ensure these components operate efficiently.

- Maintenance Matters: Regular coolant flushes, hose inspections, and temperature monitoring are vital to maintaining the cooling system’s integrity.

- Tailored Solutions: The choice of components should align with your build’s goals—whether for the street, track, or drag strip.

- Learning from Examples: Real-world case studies emphasize the importance of selecting quality components, proper installation, and proactive maintenance.

Upgrading your 2JZ’s cooling system isn’t just about chasing horsepower; it’s about ensuring the longevity and reliability of your investment. With the insights and strategies outlined in this guide, you now have the tools to design a cooling system that meets your specific needs and outperforms the competition.

- Explore the recommended products and brands mentioned in this guide.

- Share this article with fellow 2JZ enthusiasts to help them build reliable and high-performance engines.

- Subscribe to our blog for more in-depth guides on optimizing your 2JZ and other performance engines.

By implementing these strategies, your 2JZ will stay cool under pressure, enabling you to unleash its full potential safely and confidently. The road to big power is challenging, but with the right cooling system, your 2JZ is ready to conquer it.

FAQ: Upgrading Your 2JZ Cooling System for Big Power Builds

How can I keep my 2JZ engine cool under high-power conditions?

To keep your 2JZ engine cool, consider the following upgrades:

- Install a high-capacity radiator: Aluminum radiators from brands like Mishimoto and Koyorad dissipate heat more efficiently than stock units.

- Use an efficient intercooler: An air-to-air or air-to-water intercooler reduces intake air temperatures, preventing detonation.

- Upgrade your oil cooler: A high-performance oil cooler like those from Setrab or HKS helps maintain optimal oil temperatures.

- Enhance airflow: Electric fans with high CFM ratings, like SPAL or Flex-A-Lite, ensure proper airflow through the radiator and intercooler.

- Use high-performance coolant: Products like Engine Ice or Red Line Water Wetter improve heat transfer and reduce the risk of overheating.

What are the signs that my 2JZ cooling system needs an upgrade?

Common indicators that your cooling system is insufficient for high-power builds include:

- Overheating during spirited driving or prolonged use: Coolant or oil temperatures exceed safe operating limits.

- Coolant leaks or low levels: Indicate that the system is under pressure or components are worn out.

- Inconsistent temperature readings: Fluctuations on temperature gauges suggest air pockets or restricted coolant flow.

- Boiling coolant or steam: A sign of extreme overheating and inadequate radiator performance.

- Decreased performance: Heat soak can reduce engine efficiency and output.

Which radiator is best for a high-performance 2JZ engine?

The ideal radiator depends on your specific build, but top recommendations include:

- Mishimoto Performance Radiators: Dual-pass designs with large cores, ideal for street and track use.

- Koyorad Racing Radiators: Lightweight and optimized for high horsepower applications.

- CSF Radiators: Triple-pass models designed for maximum cooling efficiency. When choosing a radiator, consider its core size, material (aluminum is preferred), and compatibility with your engine bay.

Do I need an air-to-water intercooler for my 2JZ build?

An air-to-water intercooler is highly effective for specific applications, such as drag racing or extreme power builds, where keeping intake air temperatures low during short, intense runs is critical. Advantages include:

- Superior cooling efficiency: Air-to-water systems can significantly lower intake temperatures using a water reservoir or ice.

- Compact design: Easier to fit in tight engine bays. However, for most street and track builds, an air-to-air intercooler is sufficient due to its simpler design, lower cost, and consistent performance.

What maintenance does a high-performance cooling system require?

Regular maintenance ensures your cooling system operates at peak efficiency. Key tasks include:

- Coolant flushes: Replace coolant every 12-24 months to prevent buildup and maintain effectiveness.

- Hose inspections: Check silicone or rubber hoses for cracks, bulges, or wear, and replace them if needed.

- Radiator cleaning: Clear debris from fins with compressed air and inspect for bent fins or leaks.

- Oil cooler upkeep: Inspect lines for leaks or damage, and replace the filter (if applicable) regularly.

- Fan and pump checks: Verify that electric fans and water pumps are operating as intended using temperature gauges or diagnostic tools.