The Legendary 2JZ Engine and Its Turbo Potential

The Toyota 2JZ engine is nothing short of a legend in the world of automotive performance. Known for its bulletproof reliability and almost infinite tuning potential, it has become the heart of countless high-horsepower builds. One of the most exciting aspects of the 2JZ is its factory twin-turbo setup, which is often turbo-swapped with larger single turbos or entirely different configurations to meet specific performance goals.

In this guide, we will walk you through the process of upgrading from the stock twin-turbo setup to more powerful turbo configurations. This comprehensive resource will not only help you understand the “why” and “how” of 2JZ tuning but also ensure your build stands out in terms of performance, reliability, and innovation.

Key Takeaways of This Guide

- Understanding the Stock Setup: Why the factory twin-turbo is both a blessing and a limitation.

- Turbocharger Selection: How to choose the right turbo for your power goals.

- Supporting Modifications: Essential upgrades to fuel, cooling, and exhaust systems.

- Engine Management: Why a standalone ECU is critical for success.

- Real-World Insights: Learn from successful 2JZ builds and apply their lessons to your project.

Whether you’re chasing a 600-700HP street car or a monstrous 1000HP+ track beast, this article will be your go-to guide.

The Legacy of the 2JZ Engine

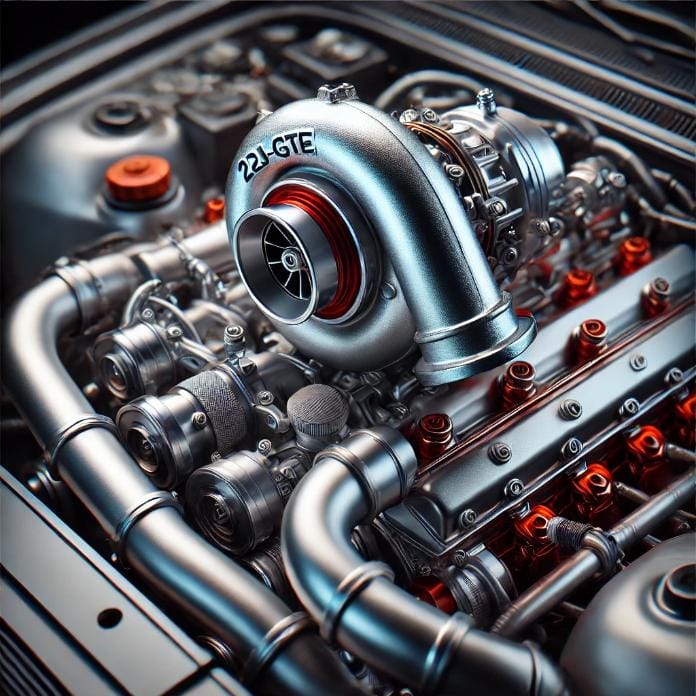

What Makes the 2JZ Engine Special?

The 2JZ engine, especially the 2JZ-GTE variant, is a marvel of engineering. Introduced by Toyota in the early 1990s, it quickly gained recognition for its robust iron block, overengineered components, and immense tuning potential. Its ability to handle upwards of 800HP on stock internals is a testament to its durability, making it a favorite among tuners worldwide.

Key Features of the 2JZ-GTE:

- 3.0L Inline-6 Design: Delivers smooth power and torque.

- Iron Block: Unparalleled strength for high boost levels.

- Forged Internals: Stock pistons, rods, and crankshaft capable of enduring extreme conditions.

- Sequential Twin-Turbo System: Factory setup designed for efficiency and drivability.

The Variants: 2JZ-GTE vs. 2JZ-GE

- 2JZ-GTE (Twin Turbo):

- Found in the Toyota Supra MKIV and Aristo.

- Designed with performance in mind, featuring forged internals and oil squirters for added cooling.

- 2JZ-GE (Naturally Aspirated):

- Found in vehicles like the Toyota Altezza and Lexus IS300.

- While it lacks turbocharging, its strong foundation makes it a popular candidate for turbo swaps.

Why the 2JZ Is Still Relevant Today

The 2JZ’s reputation has endured decades due to its versatility. Whether you’re building a street monster or a drag racer, the 2JZ can handle it all. Its strong aftermarket support ensures there’s no shortage of parts or expertise, keeping it at the forefront of the tuning world.

Stock Twin-Turbo Setup

Strengths and Limitations of the Factory Twin-Turbo Configuration

The stock twin-turbo system on the 2JZ-GTE was designed for a balance of power, efficiency, and reliability. Featuring a sequential configuration, the system uses two CT12B turbochargers that work together to minimize lag and maximize drivability. While the factory setup was groundbreaking in its era, it has limitations for those chasing higher horsepower numbers.

Strengths:

- Low-End Power Delivery: The sequential system provides strong torque at lower RPMs by engaging one turbo first, ensuring smooth power delivery.

- Factory Reliability: Toyota engineered the system for durability, handling up to ~400HP without significant modifications.

- Ideal for Daily Driving: The design minimizes lag and maximizes responsiveness, making it perfect for street use.

Limitations:

- Power Ceiling: The stock turbos are small and limit the engine’s ability to achieve high boost levels, capping power output around 450HP.

- Heat Management Issues: The small turbochargers generate significant heat, which can lead to heat soak and reduced performance under sustained load.

- Complexity of the Sequential System: The complexity of controlling two turbos often leads tuners to simplify or replace the system with a single turbo.

Why Upgrade the Twin-Turbo Setup?

For enthusiasts looking to push the limits of the 2JZ, the factory twin-turbo setup is a bottleneck. Here’s why many tuners consider upgrading:

- Higher Power Goals: Achieving 600-700HP or more requires a larger, more efficient turbo system.

- Simplified Design: A single turbo system reduces complexity and maintenance.

- Customizable Boost Characteristics: Larger turbos offer more flexibility in tuning boost levels to match specific goals.

Comparison: Stock Twin-Turbo vs. Upgraded Turbo Configurations

| Feature | Stock Twin-Turbo | Upgraded Turbo Configurations |

| Power Output | ~350-450HP | 600HP+ (single turbo setups) |

| Turbo Lag | Minimal | Moderate (depends on turbo size) |

| Ease of Maintenance | Complex (dual turbos) | Simplified (single turbo) |

| Customizability | Limited | High |

What You Need to Know Before Upgrading

- Supporting Mods Are Critical: The factory fuel system, cooling system, and ECU must all be upgraded to handle the increased power and boost from larger turbos.

- Consider Your Goals: If you’re looking for a balanced street build, the factory twin-turbo might suffice with minor upgrades. For high horsepower, a turbo swap is inevitable.

Choosing the Right Turbocharger

Single vs. Twin Turbo: What’s Best for Your Build?

One of the most significant decisions in upgrading a 2JZ turbo system is whether to opt for a single turbo or stick with a twin-turbo configuration. Each option has its own advantages, but your choice will depend on your specific goals, budget, and driving style.

Benefits of a Single Turbo Setup:

- Higher Peak Power: A larger single turbo can generate significantly more airflow, resulting in greater power potential.

- Simpler Design: Fewer moving parts and less complexity compared to twin turbos.

- Customizable Boost Levels: With precise tuning, single turbos can offer adjustable boost tailored to your needs.

Drawbacks:

- Turbo Lag: Larger turbos often have increased lag, though this can be mitigated with proper tuning and supporting modifications.

Advantages of a Twin Turbo Setup:

- Quick Spool: Smaller turbos spool faster, providing immediate power.

- Versatility: Sequential systems provide both low-end response and high-end power.

Drawbacks:

- Complexity: Dual turbos require more components and are harder to maintain.

- Power Ceiling: Factory or even upgraded twin turbos are limited in maximum power output.

Factors to Consider When Choosing a Turbo

- Power Goals

- Are you aiming for a streetable 500-700HP setup or an all-out 1000+HP build?

- Example: A Precision 6266 is ideal for street builds, while a Garrett GTX42R caters to extreme power.

- Intended Use

- Daily driving: Opt for a mid-sized single turbo (~60mm compressor inducer).

- Drag racing or high-horsepower builds: A larger turbo (~70mm+) may be more suitable.

- Turbocharger Brands

- Precision Turbo: Known for high-efficiency compressors, perfect for street and track builds.

- Garrett: Industry leader with a range of turbos for various power levels.

- BorgWarner: Offers durable options with innovative technology like the EFR series.

Understanding Key Turbocharger Specs

| Specification | Description |

| Compressor Inducer | Determines the size of the turbo and its airflow capabilities. |

| A/R Ratio | Affects spool time and maximum boost. Smaller A/R = faster spool, but less top-end power. |

| Journal vs. Ball Bearing | Ball bearings offer quicker spool but are more expensive than journal bearings. |

Popular Turbo Choices for 2JZ Builds

| Turbo Model | Horsepower Range | Key Features |

| Precision 6266 | 600-700HP | Excellent spool characteristics and streetability. |

| Garrett GTX3582R | 700-850HP | Dual ball bearing with outstanding efficiency. |

| BorgWarner S366 | 800-1000HP | Cost-effective and durable for high boost. |

| Garrett GTX4202R | 1000HP+ | Ideal for extreme builds needing massive airflow. |

Avoiding Mismatched Turbos

Selecting a turbo that’s too large or too small can lead to performance issues:

- Too Small: Chokes top-end power and limits boost potential.

- Too Large: Results in excessive turbo lag and makes the car less responsive for street driving.

How to Match a Turbo to Your 2JZ Build

- Displacement: The 3.0L capacity of the 2JZ supports a wide range of turbo sizes.

- RPM Range: Decide where you want peak power (mid-range vs. high RPMs).

- Supporting Mods: Ensure your fuel system, ECU, and exhaust can handle the turbo’s airflow.

Supporting Modifications

Upgrading the turbocharger on your 2JZ is only one part of the equation. To unlock the full potential of your build, you must ensure that critical supporting systems are upgraded to handle the increased power, boost, and airflow. Below, we’ll break down the key modifications needed for a reliable and high-performing setup.

Fuel System Upgrades

As you increase boost and power, the stock fuel system will struggle to deliver enough fuel to maintain proper air-fuel ratios (AFRs). Upgrading the fuel system ensures consistent and sufficient fuel delivery.

Essential Fuel System Components:

- Fuel Injectors: High-flow injectors (e.g., 1,000cc or larger) are necessary for high-horsepower builds.

- Brands: DeatschWerks, Injector Dynamics.

- Fuel Pump: Upgrade to a high-flow pump, such as the Walbro 450 or AEM 380, to handle increased fuel demands.

- Fuel Pressure Regulator: An adjustable regulator ensures stable fuel pressure at higher boost levels.

- Fuel Lines and Rails: Reinforced fuel lines and upgraded rails reduce restrictions in fuel flow.

Key Consideration: Use E85 for its higher octane and cooling properties, but ensure your fuel system is compatible with ethanol.

Cooling System Enhancements

Increased boost and power levels generate significant heat. Without proper cooling, overheating can lead to performance loss or catastrophic engine failure.

Upgrades to Consider:

- Front-Mount Intercooler (FMIC):

- Essential for cooling intake air and preventing heat soak.

- Sizing Tip: Larger intercoolers (~600mm x 300mm) offer better cooling for high-boost setups.

- Radiator Upgrade:

- Aluminum radiators provide better heat dissipation compared to stock units.

- Popular Choices: Mishimoto, Koyo.

- Oil Cooler:

- Helps maintain optimal oil temperatures during extended high-performance driving.

Pro Tip: Use high-quality coolant and consider adding a water/methanol injection kit for added cooling and knock resistance.

Exhaust System Modifications

To maximize turbo efficiency, the exhaust system must be upgraded to handle the increased flow.

Key Upgrades:

- Turbo Manifold:

- Choose a high-quality stainless steel or cast iron manifold to ensure durability under high heat.

- Equal-length runners improve exhaust flow and turbo spool time.

- Downpipe and Cat-Back Exhaust:

- A 3-4” downpipe with a free-flowing exhaust reduces backpressure and allows the turbo to spool faster.

- Wastegate and Blow-Off Valve:

- External wastegates (e.g., 44mm+) offer better boost control.

- A blow-off valve prevents compressor surge during gear changes.

Transmission and Drivetrain Reinforcements

With more power comes greater stress on the drivetrain. The stock 2JZ transmission and drivetrain components may need upgrades.

Recommended Modifications:

- Transmission: Upgrade to the Toyota V160 (6-speed manual) or a built automatic transmission.

- Clutch: A heavy-duty clutch kit is essential for handling the added torque.

- Differential and Axles: Reinforced components ensure power is delivered to the wheels reliably.

Electrical and Ignition Upgrades

Proper spark and ignition timing are crucial for achieving optimal combustion under high boost.

Ignition Components:

- Coil Packs: Upgrade to high-performance coils to ensure strong spark at high boost levels.

- Spark Plugs: Use colder heat range spark plugs (e.g., NGK BKR7EIX) to prevent pre-ignition.

Electrical Upgrades:

- Battery and Alternator: Ensure your electrical system can support additional fuel and ignition demands.

- Wiring Harness: A custom or upgraded harness simplifies installation and improves reliability.

Checklist for Supporting Modifications

| Component | Recommended Upgrade | Key Brands |

| Fuel Injectors | 1,000cc+ | DeatschWerks, Injector Dynamics |

| Fuel Pump | Walbro 450 or AEM 380 | Walbro, AEM |

| Intercooler | Large Front-Mount Intercooler (FMIC) | Mishimoto, GReddy |

| Radiator | Aluminum radiator | Koyo, Mishimoto |

| Exhaust System | 3-4” downpipe with free-flowing exhaust | HKS, Tomei |

| Ignition System | High-performance coil packs and colder spark plugs | NGK, Toyota OEM |

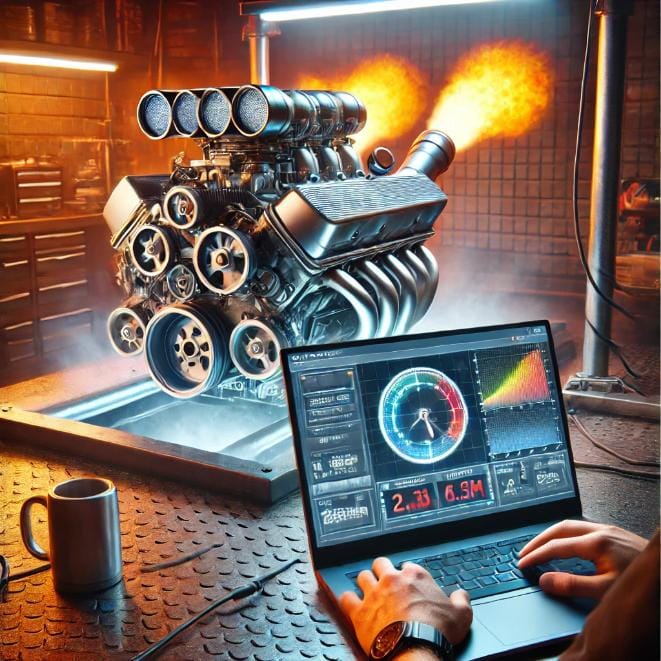

Engine Management and Tuning

When upgrading the turbocharger on your 2JZ engine, tuning plays a pivotal role in maximizing performance, ensuring reliability, and avoiding catastrophic failures. Proper engine management allows you to control essential parameters like air-fuel ratios (AFRs), ignition timing, and boost pressure, ensuring your turbocharged 2JZ runs efficiently and safely.

Why Engine Management is Crucial

- Performance Optimization: Ensures the engine runs at peak efficiency, delivering maximum horsepower and torque.

- Reliability: Prevents issues like detonation, overheating, or fuel starvation that could damage your engine.

- Adaptability: Allows you to tailor your setup for specific goals, such as street performance, track racing, or drag racing.

Standalone Engine Management Systems (ECUs)

A standalone ECU replaces the factory ECU, providing greater control and tunability. For turbo-swapped 2JZ builds, a standalone ECU is often non-negotiable.

Recommended Standalone ECUs:

- AEM EMS V2:

- Popular among 2JZ tuners for its user-friendly interface and extensive tuning capabilities.

- Supports advanced features like boost control and launch control.

- Haltech Elite 2500:

- Offers unparalleled precision with real-time data logging and advanced tuning options.

- Ideal for high-power builds needing precise fuel and ignition control.

- Link G4+ Extreme:

- Known for reliability and excellent integration with 2JZ engines.

- Budget-friendly compared to other standalone options.

Key Features to Look For:

- Boost control management.

- Wideband oxygen sensor integration for accurate AFR monitoring.

- Real-time data logging for tuning adjustments.

Tuning Software and Tools

Proper tuning requires the right software and diagnostic tools to dial in your turbo setup.

Popular Tuning Tools:

- HP Tuners: Offers flexibility and compatibility with standalone ECUs.

- ECU Master: Ideal for advanced tuning and diagnostics.

- Wideband O2 Sensors: Critical for monitoring AFRs during tuning (e.g., Innovate LC-2 or AEM X-Series).

Key Tuning Parameters

- Air-Fuel Ratios (AFRs)

- Boosted Engines: Target an AFR of 11.5-12.0 for maximum power without risking lean conditions.

- Idle and Cruising: AFRs should remain between 14.5-15.0 for efficiency.

- Tools to Monitor AFRs: Use wideband oxygen sensors for precise readings.

- Ignition Timing

- Boost Timing Retard: Timing should be progressively retarded as boost pressure increases to avoid detonation.

- Safe Ignition Timing Example: Start with 20-25 degrees at low RPM, reducing to 10-15 degrees under heavy boost.

- Boost Control

- Manual Boost Controllers: Simple and affordable, but less precise.

- Electronic Boost Controllers: Provide greater accuracy and control, integrating seamlessly with standalone ECUs.

Dyno Tuning vs. Road Tuning

- Dyno Tuning:

- Provides controlled conditions for fine-tuning AFRs, ignition timing, and boost levels.

- Essential for high-horsepower builds.

- Road Tuning:

- Allows tuners to test real-world conditions, especially for drivability and throttle response.

- Often combined with dyno tuning for optimal results.

Fuel Maps and Timing Maps

Modern standalone ECUs allow the creation of precise maps for fuel delivery and ignition timing. Examples include:

- Boost-Specific Fuel Maps: Adjust fuel delivery for varying boost levels.

- RPM-Specific Timing Maps: Tailor ignition timing to match power delivery goals.

Checklist for Tuning Success

| Tuning Parameter | Target Range | Tools Needed |

| Air-Fuel Ratios | 11.5-12.0 (boost) / 14.5-15.0 (cruise) | Wideband O2 sensor |

| Ignition Timing | 10-25 degrees (varies by boost) | ECU tuning software |

| Boost Control | Match boost level with AFR and timing | Electronic boost controller |

| Fuel Pressure | 40-50 PSI (boost reference) | Adjustable fuel pressure regulator |

Common Tuning Challenges

- Knock and Detonation

- Signs: Audible knocking under load or melted spark plugs.

- Solution: Retard ignition timing and ensure AFRs are on target.

- Fuel Delivery Issues

- Signs: Lean AFRs, fuel starvation at high RPMs.

- Solution: Upgrade fuel pump, injectors, and regulator as needed.

- Overboost Conditions

- Signs: Boost levels exceeding safe limits for your setup.

- Solution: Install a reliable wastegate and configure boost control settings.

Tuning Specifics for Turbo-Swapped 2JZs

Swapping the stock twin-turbo system for a single turbo or alternative configurations requires a nuanced approach to tuning. Achieving optimal performance while maintaining reliability demands a detailed understanding of key tuning parameters specific to turbo-swapped 2JZ builds.

Air-Fuel Ratios (AFRs) for Turbo-Swapped Builds

- Why AFR Matters: The AFR determines the balance between fuel and air in the combustion process. A lean mixture (too much air) risks detonation, while a rich mixture (too much fuel) causes loss of power and carbon build-up.

- Optimal AFR Targets:

- Idle and cruising: 14.5–15.0 for fuel efficiency.

- Boosted operation: 11.5–12.0 for safe and powerful combustion.

- How to Monitor AFRs:

- Install a wideband O2 sensor (e.g., AEM X-Series or Innovate LC-2).

- Use data logging tools to track AFR trends during tuning.

Ignition Timing Adjustments

Proper ignition timing is critical for turbo-swapped builds, as higher boost levels increase the risk of detonation.

- Boost-Specific Timing Adjustments:

- Lower boost levels: Advance timing to improve response (20–25 degrees).

- Higher boost levels: Retard timing (10–15 degrees) to prevent knock.

- How to Tune Timing:

- Use tuning software integrated with your standalone ECU.

- Monitor knock levels using a knock sensor or audio detection tool.

Boost Control Management

Controlling boost pressure is a cornerstone of tuning turbo-swapped 2JZ builds. Proper boost management ensures safe operation and consistent power delivery.

Boost Control Options:

- Manual Boost Controllers (MBC):

- Simple, affordable, and effective for low-boost setups.

- Example: TurboSmart MBC.

- Electronic Boost Controllers (EBC):

- Precise control over boost levels and ramp rates.

- Recommended: GReddy Profec or AEM Tru-Boost.

- Wastegate Tuning:

- External wastegates provide superior boost control for high-power setups.

- Ensure proper spring pressure matches your target boost level.

Fine-Tuning Fuel Maps

Fuel mapping adjusts fuel delivery based on RPM and boost levels, ensuring consistent AFRs throughout the powerband.

Steps for Fuel Mapping:

- Create Base Maps:

- Start with a conservative map for idle, cruising, and light throttle.

- Boost-Specific Fuel Adjustments:

- Increase fuel delivery proportionally with boost pressure.

- Refine Under Load:

- Test and adjust maps on a dyno to ensure stable AFRs at all boost levels.

Dyno Tuning Tips

A dyno provides the controlled environment needed to refine key tuning parameters for turbo-swapped builds.

What to Test on the Dyno:

- Wideband AFR Readings: Ensure target AFRs under load.

- Torque and Horsepower Curves: Analyze where the engine produces peak power and adjust timing and fuel delivery for smoother power bands.

- Boost Ramp Rates: Optimize spool characteristics to suit your driving goals.

Case Example: Tuning a 700HP Single-Turbo 2JZ

- Turbo Setup: Garrett GTX3582R with 1.06 A/R housing.

- Fuel System: 1,000cc injectors, Walbro 525 fuel pump, and an adjustable regulator.

- ECU: AEM EMS V2 with electronic boost control.

- Tuning Parameters:

- AFR under boost: 11.8.

- Timing under 20 PSI boost: 12 degrees at peak torque.

- Results:

- Peak Power: 705HP @ 6,800 RPM.

- Boost Threshold: Full boost at 3,800 RPM.

- Drivability: Smooth power delivery with minimal lag.

Common Challenges in Tuning Turbo-Swapped 2JZs

- Boost Creep:

- Cause: Inefficient wastegate or exhaust setup.

- Solution: Use larger wastegates or improve exhaust flow.

- Lean Conditions at High RPMs:

- Cause: Insufficient fuel delivery.

- Solution: Upgrade injectors or fuel pump.

- Knock and Detonation:

- Cause: Excessive ignition timing or lean AFRs.

- Solution: Retard timing and enrich fuel maps.

Checklist for Turbo-Swapped Tuning

| Parameter | Target Values | Tools Needed |

| Air-Fuel Ratios | 11.5–12.0 (boost) | Wideband O2 sensor |

| Ignition Timing | 10–25 degrees (varies) | ECU tuning software, knock detection |

| Boost Levels | Match turbo capacity | Electronic or manual boost controller |

| Fuel Pressure | 40–50 PSI (boost ref.) | Adjustable fuel pressure regulator |

Advanced Turbo Configurations

For enthusiasts looking to push the limits of their 2JZ build or explore innovative approaches to turbo setups, advanced configurations offer exciting opportunities. Whether it’s compound turbocharging or custom hybrid setups, these advanced configurations can deliver exceptional performance and versatility.

Compound Turbocharging: Maximizing Power Across the RPM Range

What is Compound Turbocharging? Compound turbocharging involves using a smaller turbocharger for quick spool and low-end torque, paired with a larger turbo for high-end power. This setup is ideal for those who want to eliminate turbo lag while maintaining the ability to produce massive power.

Advantages of Compound Turbocharging:

- Full Powerband Coverage: Instant boost at low RPMs and sustained power at high RPMs.

- Efficient Boost Delivery: The smaller turbo feeds the larger one, ensuring smoother transitions.

- Ideal for Versatility: Suitable for both street and track applications.

Challenges:

- Complexity: Requires precise engineering and tuning to balance both turbos.

- Cost: Additional components like custom manifolds and intercooler piping increase the expense.

Parallel Twin-Turbo Setups: Revival of a Classic Approach

What is Parallel Twin-Turbocharging? Unlike the sequential system found in the stock 2JZ-GTE, parallel twin-turbo setups use two identical turbos running simultaneously. Each turbo handles half the engine’s airflow, ensuring even power delivery.

Benefits:

- Reduced Turbo Lag: Two smaller turbos spool faster than one large turbo.

- Balanced Airflow: Improved response in mid-range RPMs.

Drawbacks:

- Power Ceiling: Limited airflow compared to larger single turbos.

- Space Constraints: Fitting two larger turbos requires creative engineering.

Hybrid Turbo Designs: Bridging the Gap

Hybrid turbos combine features of smaller, faster-spooling turbos and larger, high-power turbos. This is achieved by using advanced compressor and turbine designs tailored to the desired powerband.

Key Features:

- Quick Spool: Smaller turbine housings ensure reduced lag.

- High Top-End Power: Larger compressor wheels allow for increased airflow.

- Applications: Perfect for enthusiasts who need both low-end drivability and high-end performance.

Examples of Hybrid Turbos:

- Garrett GTX series: Known for combining fast spool and top-end power.

- Precision Turbo’s Gen 2 series: Offers cutting-edge aerodynamics for hybrid setups.

Comparing Advanced Turbo Configurations

| Configuration | Strengths | Challenges |

| Compound Turbo | Full powerband coverage, no lag | Complex design, high cost |

| Parallel Twin | Faster spool, balanced power delivery | Space and power limitations |

| Hybrid Turbo | Best of both worlds (spool and power) | Custom tuning required |

When to Consider Advanced Configurations

- Power Goals:

- Compound setups are ideal for extreme power (1000HP+).

- Parallel twin-turbos suit builds in the 600–800HP range.

- Hybrid turbos are versatile for street and track builds.

- Application:

- Drag racing: Compound turbos for consistent power delivery.

- Time Attack or Circuit Racing: Parallel or hybrid setups for quick response.

- Budget:

- Advanced setups require significant investment in engineering, components, and tuning. Ensure your budget aligns with your goals.

Components for Advanced Turbo Configurations

- Custom Manifolds and Piping: Designed to handle airflow distribution in compound or twin setups.

- Dual Wastegates: Required for precise boost control in twin-turbo or compound configurations.

- Intercooler Systems: Large, efficient intercoolers to manage increased airflow and heat.

Real-World Case Study: Compound Turbo 2JZ Build

- Setup: Small Precision 5858 turbo paired with a large Garrett GTX4202R.

- Results:

- Spool starts at 2,500 RPM with full boost by 3,800 RPM.

- Peak power: 1,200HP at 7,000 RPM.

- Challenges: Required extensive tuning to synchronize turbo transitions.

Advanced Configurations: The Final Verdict

For those aiming to stand out with a unique and powerful build, advanced turbo configurations provide incredible opportunities. However, they require a detailed understanding of engineering, tuning, and the interplay between components. These setups are not for the faint-hearted but can deliver unparalleled results for those willing to invest the time and resources.

Common Pitfalls and Troubleshooting

Building and tuning a turbocharged 2JZ engine is an exciting but complex process. Even seasoned tuners can encounter challenges that, if not addressed, could compromise performance, reliability, or both. This section will walk you through the most common pitfalls and how to troubleshoot them effectively.

1. Boost Leaks and Pressure Issues

Symptoms:

- Loss of power under boost.

- Inconsistent AFR readings.

- Slow turbo spool or failure to reach target boost levels.

Causes:

- Loose or damaged intercooler piping or couplers.

- Cracked or improperly installed intake manifold gaskets.

- Faulty blow-off valve or wastegate seals.

Solutions:

- Perform a boost leak test using a pressure tester and soapy water.

- Tighten or replace damaged couplers and clamps.

- Inspect and replace faulty gaskets or seals.

2. Overheating Problems

Symptoms:

- High engine temperatures during extended boost runs.

- Coolant overflow or leaks from the radiator.

- Reduced engine performance after repeated pulls.

Causes:

- Insufficient cooling capacity for higher power output.

- Air pockets in the cooling system.

- Overworked stock radiator or oil cooling system.

Solutions:

- Upgrade to a high-capacity aluminum radiator and large front-mount intercooler.

- Add an oil cooler for extended high-performance driving.

- Properly bleed the cooling system to remove air pockets.

3. Fuel Starvation and Lean Conditions

Symptoms:

- Lean AFR readings under heavy throttle.

- Misfires or hesitation at high RPMs.

- Detonation or knocking under boost.

Causes:

- Insufficient fuel pump or injector capacity.

- Clogged fuel filter or restrictive fuel lines.

- Faulty fuel pressure regulator.

Solutions:

- Upgrade to high-flow fuel pumps and injectors matched to your power goals.

- Inspect and replace the fuel filter regularly.

- Use a fuel pressure gauge to ensure consistent pressure during boost.

4. Turbocharger Overspeed and Failure

Symptoms:

- Whining or scraping noises from the turbo.

- Smoke from the exhaust (blue or gray).

- Excessive shaft play when inspected manually.

Causes:

- Boost levels exceeding the turbo’s design limits.

- Insufficient oil supply or contamination.

- Foreign object damage to the compressor or turbine blades.

Solutions:

- Install a reliable boost controller to limit boost pressure.

- Use high-quality, turbo-rated oil and replace it frequently.

- Ensure proper filtration for both intake air and oil supply.

5. Knock and Detonation

Symptoms:

- Audible “pinging” noises under load.

- Melted or damaged spark plugs.

- Loss of power and increased engine temperatures.

Causes:

- Excessive ignition timing advance.

- Lean AFRs due to insufficient fuel delivery.

- Low-octane fuel or excessive boost pressure.

Solutions:

- Retard ignition timing for higher boost levels.

- Ensure AFRs are within the safe range of 11.5-12.0 during boost.

- Use high-octane fuel or switch to E85 for its higher resistance to knock.

6. Wastegate and Boost Control Issues

Symptoms:

- Boost spikes or inconsistent boost levels.

- Failure to hit target boost.

- Slow turbo spool or excessive lag.

Causes:

- Incorrect wastegate spring pressure.

- Leaking or damaged boost control solenoid.

- Improperly routed vacuum lines.

Solutions:

- Verify that the wastegate spring matches your target boost level.

- Test and replace faulty solenoids.

- Double-check vacuum line routing for leaks or incorrect connections.

7. Exhaust Backpressure and Flow Restrictions

Symptoms:

- High EGTs (Exhaust Gas Temperatures).

- Reduced top-end power.

- Slow turbo spool.

Causes:

- Overly restrictive exhaust system (e.g., stock downpipe or catalytic converter).

- Improperly sized turbo manifold or exhaust piping.

Solutions:

- Upgrade to a 3-4” free-flowing exhaust system with minimal restrictions.

- Use a high-quality turbo manifold with equal-length runners for balanced flow.

Preventive Measures for a Reliable Build

| Issue | Preventive Action |

| Boost Leaks | Perform routine boost leak tests. |

| Overheating | Upgrade the cooling system before increasing power. |

| Fuel Starvation | Match the fuel system capacity to power goals. |

| Turbo Overspeed | Monitor and regulate boost levels. |

| Detonation | Use proper tuning and high-octane fuel. |

Tips for Efficient Troubleshooting

- Data Logging is Key: Use your standalone ECU to log parameters like AFRs, boost pressure, and ignition timing for easy diagnosis.

- Start Simple: Begin with the most common and easily fixable causes before moving on to complex issues.

- Consult Experts: Online communities like SupraForums or ClubLexus, along with professional tuners, can provide valuable insights.

Real-World Case Studies

Learning from successful builds and real-world applications is one of the most effective ways to gain insight and inspiration for your own 2JZ turbo swap project. Below, we’ve compiled examples of turbo-swapped 2JZ builds that highlight different goals, configurations, and lessons learned.

Case Study 1: 700HP Single-Turbo Street Build

Build Overview:

- Vehicle: Toyota Supra MKIV

- Turbo Setup: Precision 6266 single turbo with 1.0 A/R.

- Supporting Mods:

- 1,000cc injectors and Walbro 525 fuel pump.

- AEM EMS V2 standalone ECU.

- GReddy front-mount intercooler and Koyo radiator.

- Custom 3.5” downpipe and cat-back exhaust.

Results:

- Dyno Numbers: 705HP at 6,500 RPM, 640 lb-ft of torque.

- Boost Threshold: Full boost achieved by 3,500 RPM.

- Drivability: Excellent throttle response with minimal turbo lag, making it suitable for daily driving.

Key Takeaway:

A properly sized turbo, combined with balanced supporting modifications, can achieve high horsepower while retaining street-friendly characteristics.

Case Study 2: 1000HP Drag Racing Monster

Build Overview:

- Vehicle: Lexus IS300 with a 2JZ-GTE swap.

- Turbo Setup: Garrett GTX4202R with a 1.28 A/R housing.

- Supporting Mods:

- 2,200cc injectors and dual Bosch 044 fuel pumps.

- Haltech Elite 2500 ECU with custom tuning for E85 fuel.

- Full aluminum radiator and custom oil cooling system.

- Welded differential and upgraded axles for power delivery.

Results:

- Dyno Numbers: 1,050HP at 7,200 RPM, 900 lb-ft of torque.

- Boost Threshold: Full boost achieved at 4,200 RPM.

- 1/4-Mile Time: 8.9 seconds at 150 MPH.

Key Takeaway:

Extreme builds require robust drivetrain reinforcements and precise tuning to handle the stress of drag racing. E85 fuel played a crucial role in preventing detonation under high boost.

Case Study 3: 600HP Budget-Friendly Build

Build Overview:

- Vehicle: Toyota Altezza with a 2JZ-GE + Turbo conversion.

- Turbo Setup: BorgWarner S366 single turbo.

- Supporting Mods:

- 750cc injectors and Walbro 450 fuel pump.

- Piggyback ECU (Greddy e-Manage).

- Upgraded intercooler and 3” exhaust.

Results:

- Dyno Numbers: 605HP at 6,000 RPM, 500 lb-ft of torque.

- Boost Threshold: Full boost achieved by 3,800 RPM.

- Budget: Under $10,000 for the entire build.

Key Takeaway:

A well-planned budget build can still deliver impressive results. Using a piggyback ECU helped reduce costs while maintaining decent tunability.

Case Study 4: Time Attack Circuit Racer

Build Overview:

- Vehicle: Toyota Supra MKIV for competitive time attack racing.

- Turbo Setup: Twin Garrett GTX2860R Gen 2 turbos in a parallel setup.

- Supporting Mods:

- 1,200cc injectors and dual Walbro 450 fuel pumps.

- Motec M150 ECU with advanced traction control.

- Custom intercooler with water spray cooling.

- Brembo big brake kit and full coilover suspension.

Results:

- Lap Time: 1:35 on a 2-mile technical circuit.

- Boost Threshold: Instant boost response, thanks to the parallel twin-turbo setup.

- Drivability: Seamless power delivery with high corner exit speeds.

Key Takeaway:

For track builds, a twin-turbo setup offers superior response and balance, while advanced engine management ensures peak performance in demanding conditions.

Lessons Learned from These Builds

- Match Components to Goals: Turbo size, fuel system, and cooling upgrades must align with the intended use of the vehicle.

- Invest in Tuning: A standalone ECU and professional tuning can unlock significant power and reliability.

- Prioritize Reliability: High-performance builds require attention to supporting mods like cooling, fueling, and drivetrain reinforcements.

- Budget Wisely: A successful build doesn’t always require breaking the bank—prioritize essential upgrades.

Inspiration for Your Build

| Build Type | Horsepower Range | Ideal Turbo Setup | Key Supporting Mods |

| Street Build | 600–700HP | Precision 6266 | AEM EMS V2, 1,000cc injectors, FMIC |

| Drag Racer | 1,000HP+ | Garrett GTX4202R | E85 fuel system, Haltech Elite, oil cooler |

| Budget Build | 500–600HP | BorgWarner S366 | Greddy e-Manage, Walbro 450 pump |

| Circuit Racer | 600–800HP | Twin GTX2860R Gen 2 | Motec M150, water spray cooling system |

Conclusion

The Journey to Building a Turbocharged 2JZ

The Toyota 2JZ engine is a legend for a reason—it combines bulletproof reliability, incredible power potential, and an unparalleled aftermarket ecosystem. Whether you’re upgrading from the stock twin-turbo setup to a larger single turbo, exploring compound configurations, or chasing unique performance goals, the possibilities are nearly endless.

Key Takeaways

- Understanding Your Goals:

Define your horsepower targets and intended use (street, track, drag) before selecting a turbo setup. - Turbo Selection Matters:

The right turbo—whether it’s a single, twin, or compound configuration—will make or break your build. Match it to your power and response needs. - Supporting Modifications Are Critical:

Upgraded fuel systems, cooling, exhaust, and ECUs are essential to safely harness the power of your turbocharged 2JZ. - Tuning is the Difference Maker:

A proper tune unlocks peak performance while ensuring engine safety and reliability. Invest in a standalone ECU and professional tuning services. - Learn from Real-World Examples:

Drawing inspiration from successful builds can help you avoid common pitfalls and tailor your setup to your specific goals.

Encouragement for Your Build

The world of turbo-swapping and tuning a 2JZ engine is as rewarding as it is challenging. With careful planning, attention to detail, and the insights shared in this guide, your build can stand out as a true masterpiece—whether it’s a 600HP street beast or a 1,000HP track monster.

Remember, patience and precision are key. Test, tune, and refine as needed, and don’t be afraid to seek advice from the 2JZ tuning community. With every adjustment, you’re one step closer to achieving the ultimate expression of performance.

Share Your Build!

We’d love to hear about your turbocharged 2JZ projects. Drop a comment below with your setup, challenges, and successes. Let’s build a community of enthusiasts sharing knowledge and celebrating this incredible engine!

Need Help?

If you’re just starting your build or need advice on a specific aspect, feel free to reach out. Together, we can make your 2JZ dream a reality.

Final Notes

This guide was crafted to be the most comprehensive resource for turbo-swapping and tuning a 2JZ engine. If there’s anything you’d like to add, adjust, or expand upon, please let me know before finalizing it for publication.

Frequently Asked Questions (FAQ)

How Much Horsepower Can a Stock 2JZ Handle?

The stock 2JZ-GTE is renowned for its robustness and can handle around 600-700HP with the right tuning and supporting modifications. This includes a proper standalone ECU, upgraded fuel system, and an efficient cooling setup. For power levels above 700HP, you’ll need to consider strengthening the internals (e.g., forged pistons, rods, and crankshaft).

Pro Tip: While the stock 2JZ block is incredibly strong, always monitor air-fuel ratios (AFRs) and ignition timing to avoid pushing the engine beyond safe limits.

What’s the Best Turbo Setup for a 2JZ?

The best turbo setup depends on your goals:

- Street Build (600-700HP): A mid-sized single turbo like the Precision 6266 offers excellent spool and high power.

- Drag Build (800-1000HP+): Large-frame turbos such as the Garrett GTX42 series deliver massive airflow for extreme power.

- Circuit/Time Attack (500-800HP): Twin parallel turbos like the Garrett GTX2860R Gen 2 balance spool and response.

Key Considerations:

- Choose a turbo with the right A/R ratio to balance spool and power.

- Match the turbo to your fuel system and drivetrain capabilities.

What Supporting Mods Are Necessary for a Turbo-Swapped 2JZ?

Turbo-swapping a 2JZ requires several supporting modifications to ensure reliability and performance:

- Fuel System: High-flow injectors (1,000cc+), upgraded fuel pump (e.g., Walbro 525), and an adjustable fuel pressure regulator.

- Cooling System: A large front-mount intercooler, aluminum radiator, and oil cooler.

- Exhaust System: Free-flowing 3-4” exhaust with a quality turbo manifold.

- Engine Management: A standalone ECU (AEM EMS V2, Haltech Elite) for precise tuning.

- Drivetrain Upgrades: Heavy-duty clutch, strengthened axles, and a reinforced differential for higher torque.

Pro Tip: Each of these upgrades should match your target power level to avoid bottlenecks in performance.

What is the Difference Between a Twin-Turbo and Single-Turbo Setup?

- Twin-Turbo Setup:

- Uses two smaller turbos for faster spool and low-end torque.

- Ideal for street and circuit applications with moderate power goals (500-700HP).

- More complex and harder to maintain due to additional components.

- Single-Turbo Setup:

- Uses one larger turbo for higher peak power.

- Best for drag builds or extreme power (800HP+).

- Simpler design and easier to tune but can result in more lag depending on the turbo size.

Choosing the Right Setup:

If you prioritize response and drivability, consider a twin-turbo system. For top-end power, a single turbo is the superior choice.

How Do I Tune a Turbo-Swapped 2JZ for Maximum Performance?

Tuning is critical to ensure your build operates safely and efficiently. Follow these steps:

- Install a Standalone ECU: This provides full control over fuel delivery, ignition timing, and boost management.

- Set AFRs: Target 11.5-12.0 under boost for safe combustion, and 14.5-15.0 for idle and cruising.

- Adjust Ignition Timing: Retard timing at higher boost levels to prevent knock.

- Manage Boost: Use an electronic boost controller for precise control and set levels appropriate for your turbo and fuel system.

- Dyno Tune: Test and refine fuel and timing maps under controlled conditions to maximize power and reliability.

Pro Tip: Use data logging to monitor key parameters like boost pressure, AFRs, and EGTs (Exhaust Gas Temperatures) during tuning.