The Toyota 2JZ engine has cemented itself as a legendary powerhouse in the world of automotive performance. Known for its robust construction, adaptability, and ability to handle immense power, the 2JZ has become a favorite among car enthusiasts, tuners, and professional racers alike. From its use in streetcars to dominating the drag strip, this engine is synonymous with reliability and unparalleled potential for tuning.

One of the most critical aspects of maximizing the performance of a 2JZ engine lies in its ignition timing. Ignition timing—the precise moment when the spark plug ignites the air-fuel mixture in the combustion chamber—plays a pivotal role in determining the engine’s power output, efficiency, and longevity. However, achieving the perfect balance is a delicate task that requires precision and a thorough understanding of the engine’s characteristics.

In this guide, we’ll explore the role of ignition timing in tuning a 2JZ engine. We’ll dive into how timing adjustments can enhance performance, what tools and techniques are required, and how to avoid common pitfalls. Whether you’re an experienced tuner or just beginning your journey with the 2JZ, this comprehensive article will equip you with the knowledge to optimize ignition timing for both performance and reliability.

Understanding Ignition Timing

Ignition timing is a fundamental aspect of engine tuning that governs when the spark plug ignites the air-fuel mixture in the combustion chamber. This timing directly influences the efficiency of the combustion process, impacting power output, fuel economy, and engine reliability. Understanding the principles behind ignition timing is crucial to unlocking the true potential of a 2JZ engine.

What Is Ignition Timing?

Ignition timing refers to the precise moment when the spark plug fires relative to the position of the piston in the engine’s cylinder. This event is measured in degrees before the piston reaches the top dead center (TDC) on its compression stroke. Proper timing ensures that the air-fuel mixture burns efficiently, maximizing energy transfer to the engine’s moving parts.

Why Timing Matters

- Performance: Advancing ignition timing allows the air-fuel mixture more time to combust, leading to greater power output.

- Efficiency: Proper timing maximizes the engine’s fuel economy by reducing wasted energy.

- Durability: Incorrect timing can lead to knocking (detonation), which damages internal components over time.

Advanced vs. Retarded Timing

- Advanced Timing: The spark plug fires earlier in the compression stroke, providing more time for combustion. This typically results in more power and better throttle response but requires caution to avoid knocking.

- Retarded Timing: The spark plug fires later in the compression stroke. While this reduces the risk of knocking, it may lead to higher exhaust temperatures and decreased performance under normal operating conditions.

Factors Influencing Ignition Timing

Several variables affect the ideal ignition timing for an engine:

- Engine Speed (RPM): Timing must advance at higher RPMs to keep up with faster piston movement.

- Load Conditions: Under heavy loads, timing is often retarded to prevent detonation.

- Air-Fuel Ratio: Lean mixtures may require more advanced timing, while richer mixtures may ignite more quickly.

- Combustion Chamber Design: The shape and size of the combustion chamber impact flame propagation and, thus, timing requirements.

Ignition Timing in Relation to the 2JZ Engine

The 2JZ engine, whether naturally aspirated (2JZ-GE) or turbocharged (2JZ-GTE), requires precise timing adjustments to achieve optimal performance. The factory settings are calibrated for reliability and emissions compliance, leaving significant room for improvement when tuning for performance.

The Basics of the 2JZ Engine

The Toyota 2JZ engine has earned a legendary status in the automotive world due to its bulletproof design and ability to handle extreme modifications. Whether in its naturally aspirated (2JZ-GE) or turbocharged (2JZ-GTE) form, the 2JZ has become synonymous with high-performance tuning.

A Brief History of the 2JZ Engine

The 2JZ engine was introduced in the early 1990s as part of Toyota’s JZ series. It was developed to replace the M-series engines, offering a modern platform that combined power, reliability, and smooth operation. Available in various configurations, the 2JZ found its way into a range of vehicles, from luxury sedans like the Toyota Aristo to the iconic Toyota Supra MKIV.

- 2JZ-GE: The naturally aspirated version, delivering smooth power and reliability, commonly used in non-performance-oriented models.

- 2JZ-GTE: The turbocharged version, featuring forged internals, oil squirters for piston cooling, and a sequential twin-turbo system, making it a favorite among performance enthusiasts.

Key Technical Features

- Displacement: Both the 2JZ-GE and 2JZ-GTE feature a 3.0L inline-six configuration, providing excellent balance and smooth operation.

- Durability: With a cast-iron block, the 2JZ can withstand high levels of boost and horsepower, often exceeding 1,000 horsepower with proper modifications.

- VVT-i: Later versions introduced Toyota’s Variable Valve Timing with intelligence (VVT-i) system, improving efficiency and power delivery.

Why the 2JZ is Ideal for Tuning

- Robust Bottom End: The forged steel crankshaft and sturdy block design allow for immense power handling.

- Aftermarket Support: A vast array of aftermarket parts, including ECUs, turbo kits, and internals, make the 2JZ highly versatile for customization.

- Modularity: The engine’s design accommodates various upgrades, including larger turbos, intercoolers, and fuel systems, enabling tuners to push its limits.

2JZ Timing System Overview

The 2JZ’s timing system plays a crucial role in its performance and tuning potential. Key components include:

- Timing Belt: Synchronizes the crankshaft and camshaft to ensure accurate valve operation.

- Crankshaft Position Sensor: Provides data to the ECU for ignition timing adjustments.

- ECU Controls: The engine control unit manages ignition timing, especially in models equipped with VVT-i, where timing dynamically adjusts based on engine conditions.

2JZ-GE vs. 2JZ-GTE Timing Considerations

- 2JZ-GE Timing: Simpler to manage due to its naturally aspirated setup, with fewer variables affecting timing adjustments.

- 2JZ-GTE Timing: More complex, requiring careful consideration of turbo boost levels, fuel quality, and intercooling efficiency to optimize ignition timing.

The 2JZ engine’s engineering excellence provides an ideal foundation for tuning. When combined with precise ignition timing adjustments, it can deliver unparalleled performance gains while maintaining reliability.

Tools and Preparation for Timing Adjustment

Before diving into the process of adjusting ignition timing on a 2JZ engine, proper preparation is essential. This not only ensures a smooth tuning experience but also prevents costly mistakes that could damage the engine. Gathering the right tools and understanding the pre-tuning checklist will set you up for success.

Essential Tools for Timing Adjustment

To accurately set and adjust ignition timing on a 2JZ engine, you’ll need the following tools and equipment:

- Timing Light

- A crucial tool to observe and measure the timing marks on the crankshaft pulley.

- Look for a timing light with an adjustable advance feature for precise tuning.

- Diagnostic Software or ECU Tuning Tool

- Examples: Link ECU, Haltech, or EmuBlack. These tools allow you to fine-tune ignition timing maps and monitor engine data in real-time.

- Socket Set and Wrenches

- Required to loosen and adjust components like the distributor (in non-VVT-i models) or crank pulley bolts.

- RPM Tachometer

- Useful for monitoring engine speed during timing adjustments.

- Compression Gauge

- Optional but helpful for verifying engine health before making adjustments.

- Safety Gear

- Gloves, goggles, and a fire extinguisher for safe engine operation during the tuning process.

Pre-Tuning Checklist

Before making any adjustments, it’s critical to ensure the engine is in optimal condition. Neglecting these steps can lead to inaccurate adjustments or engine damage.

- Inspect Timing Belt Condition

- Ensure the timing belt is in good condition and properly tensioned. A worn or slipping belt can throw off timing accuracy.

- Verify Timing Marks

- Clean and highlight the timing marks on the crankshaft pulley and timing cover to improve visibility when using the timing light.

- Check Ignition Components

- Inspect spark plugs, ignition coils, and wiring for wear or damage. Faulty components can cause misfires and erratic timing readings.

- Fuel Quality Check

- Use high-octane fuel, especially when advancing ignition timing. This reduces the risk of detonation during tuning.

- Engine Warm-Up

- Start the engine and allow it to reach normal operating temperature. Timing adjustments are more accurate when the engine is fully warmed up.

- Baseline ECU Settings

- Reset the ECU to factory settings if previous tuning adjustments were made. This provides a clean starting point for new timing adjustments.

Safety Considerations

- Engine Stability: Secure the vehicle on a flat surface and ensure the engine is stable before making adjustments.

- Ventilation: Work in a well-ventilated area to avoid exposure to exhaust fumes.

- Monitor for Abnormalities: Keep an eye on engine temperature, knocking, or unusual sounds during tuning.

Special Considerations for 2JZ Variants

- Non-VVT-i Models: Timing adjustments often involve manual distributor movement.

- VVT-i Models: Adjustments are controlled electronically via the ECU, requiring advanced tuning tools and software.

Proper preparation ensures the accuracy of timing adjustments and minimizes the risk of issues during tuning. With the right tools and a well-prepared engine, you’re ready to move on to setting the base timing.

How to Set Base Timing on a 2JZ Engine

Setting the base timing on a 2JZ engine is a foundational step for achieving optimal ignition performance. It provides a stable baseline that can be fine-tuned further to maximize power and reliability. This section outlines a detailed step-by-step process for accurately setting base timing, along with tips for avoiding common mistakes.

What is Base Timing?

Base timing refers to the fixed timing position set on the engine when it is at idle speed, with no ECU-controlled timing adjustments. This ensures that the ignition spark occurs at the correct point in the piston’s compression stroke, forming a reliable starting point for further tuning.

Step-by-Step Guide to Setting Base Timing

- Prepare the Engine

- Ensure the engine is warmed up to normal operating temperature.

- Disconnect any accessories that may affect idle speed, such as air conditioning or power steering.

- Locate Timing Marks

- Identify the timing marks on the crankshaft pulley and timing cover.

- Highlight the factory-specified timing mark (e.g., 10° BTDC for many 2JZ configurations) using white paint or a marker for better visibility.

- Connect the Timing Light

- Attach the timing light to the first spark plug wire (cylinder #1).

- Connect the light’s power leads to the car battery, ensuring a secure connection.

- Enter Diagnostic Mode (For ECU-Controlled Models)

- For ECU-controlled 2JZ engines, locate the diagnostic port (usually near the firewall).

- Use a jumper wire to bridge the TE1 and E1 terminals. This disables dynamic timing adjustments by the ECU and locks the engine in base timing mode.

- Start the Engine and Observe the Timing Light

- Start the engine and aim the timing light at the crankshaft pulley.

- Observe the position of the highlighted timing mark relative to the timing scale on the timing cover.

- Adjust Timing (Non-VVT-i Models)

- Loosen the distributor mounting bolts slightly.

- Rotate the distributor clockwise or counterclockwise to adjust the timing until the desired timing mark aligns with the reference point on the timing scale.

- Fine-Tune Timing Using ECU (VVT-i Models)

- Access the ECU settings using a tuning tool or software.

- Adjust the base timing value in the software until the timing mark aligns correctly.

- Recheck and Tighten

- Recheck the timing with the light to ensure accuracy.

- Tighten the distributor bolts (for non-VVT-i models) or save the settings in the ECU tuning software.

- Exit Diagnostic Mode

- Remove the jumper wire from the diagnostic port to allow the ECU to resume dynamic timing control.

- Test the Engine

- Let the engine idle and observe its stability.

- Perform a few throttle blips to ensure the timing holds steady without fluctuations.

Common Errors to Avoid

- Misaligned Timing Marks: Ensure the marks are clean and properly aligned during adjustment.

- Skipping Diagnostic Mode: Failing to lock the ECU in base timing mode can result in inaccurate adjustments.

- Loose Distributor Bolts: Always secure the distributor after adjustments to prevent timing drift.

- Neglecting Fuel Quality: Using low-octane fuel can cause knocking, especially if the timing is advanced beyond the factory setting.

Special Considerations for Turbocharged 2JZ-GTE Engines

- Turbocharged engines often require slightly retarded timing to compensate for higher cylinder pressures.

- Use of high-octane fuel is essential to prevent detonation under boost.

- Monitor the knock sensor output during adjustments to ensure safe operation.

With the base timing accurately set, the engine is now ready for performance tuning. This foundational step lays the groundwork for advancing or retarding ignition timing to extract maximum power while ensuring reliability.

Tuning for Performance

Once the base timing on a 2JZ engine is correctly set, you can move on to advanced tuning for performance. Adjusting ignition timing can unlock significant gains in power, throttle response, and overall engine efficiency. However, it requires careful calibration to ensure you maximize performance without compromising reliability.

Advancing Ignition Timing

Advancing ignition timing means igniting the air-fuel mixture earlier in the piston’s compression stroke. This allows the mixture more time to burn and generate pressure, resulting in increased power and efficiency.

Benefits of Advancing Timing:

- Improved Throttle Response: Advancing timing provides sharper throttle inputs, making the car feel more responsive.

- Higher Peak Power: Properly advanced timing can deliver more horsepower, especially at high RPMs.

- Better Fuel Economy: Efficiency gains are often observed at cruise speeds, as the combustion process becomes more effective.

Steps to Advance Timing on a 2JZ Engine

- Use ECU Tuning Tools

- For VVT-i models, use a programmable ECU or tuning software (e.g., Link ECU or Haltech) to adjust timing maps.

- For non-VVT-i models, adjustments can be made via the distributor or ECU settings.

- Analyze Load and RPM Conditions

- Timing should be advanced incrementally and tested across the RPM range.

- Monitor engine load to avoid over-advanced timing under high stress.

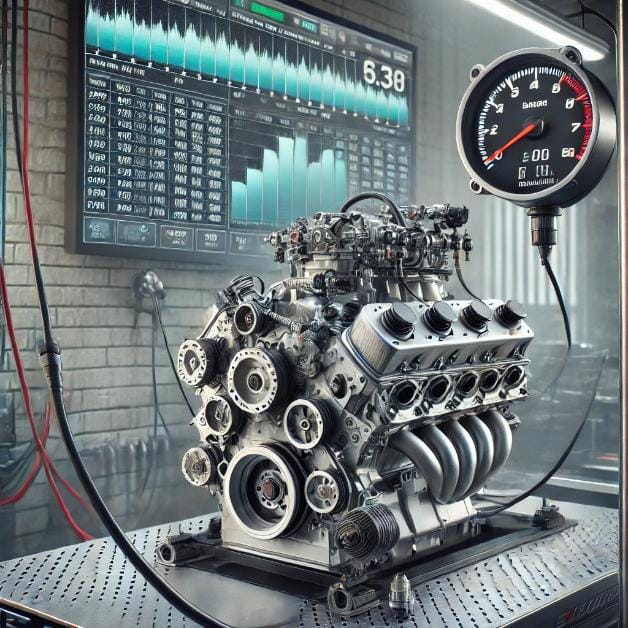

- Perform Dyno Testing

- Run the engine on a dynamometer while adjusting timing incrementally.

- Look for gains in power and torque while ensuring no signs of knocking.

- Monitor Knock Levels

- Use a knock sensor or tuning software to monitor for signs of detonation.

- If knocking occurs, reduce timing advance or use higher-octane fuel.

- Adjust Fuel Maps

- Advanced timing often requires a slightly richer air-fuel mixture to avoid detonation.

- Update the fuel maps to maintain safe combustion under advanced timing.

When Not to Advance Timing

While advancing timing has clear benefits, there are scenarios where it should be avoided:

- Under High Boost: Turbocharged engines like the 2JZ-GTE can experience detonation at high boost levels if the timing is overly advanced.

- Low-Octane Fuel: Advancing timing with insufficient fuel quality can lead to severe knocking.

- Extreme Temperatures: High intake or ambient temperatures can exacerbate detonation risk.

Case Study: Advancing Timing on a 2JZ-GTE

Scenario: A tuner advances ignition timing on a 2JZ-GTE running 15 PSI boost.

- Setup: High-octane fuel, upgraded intercooler, and forged internals.

- Outcome: Dyno results show a 7% increase in peak horsepower with no signs of knock.

- Key Learnings: The additional power was achieved by advancing timing by 2° in the mid-to-high RPM range, supported by optimized air-fuel ratios.

Testing and Verification

After advancing timing, it’s critical to verify engine performance and reliability:

- Road Testing: Perform real-world tests to ensure the engine behaves predictably under various conditions.

- Data Logging: Use ECU logging tools to monitor engine parameters, including knock, intake air temperature, and exhaust gas temperature.

- Adjust and Repeat: Fine-tune the timing map based on test results, ensuring all adjustments prioritize engine health.

Tuning ignition timing for performance requires a careful balance between power and safety. By leveraging the right tools, conducting thorough testing, and understanding the unique needs of the 2JZ engine, you can achieve impressive results.

Ensuring Engine Reliability

While tuning ignition timing on a 2JZ engine can unlock significant performance gains, maintaining reliability is just as critical. Advanced timing can push the boundaries of engine capability, but without proper precautions, it may lead to detonation, overheating, or even catastrophic engine failure. This section focuses on balancing performance with long-term durability.

Why Reliability Matters

Performance without reliability is a recipe for disaster. Ignition timing directly affects the thermal and mechanical stresses on engine components, and improper tuning can cause:

- Knocking and Detonation: Premature ignition of the air-fuel mixture leads to destructive pressure spikes.

- Excessive Heat: Advanced timing increases combustion temperatures, which may overwhelm cooling systems.

- Component Failure: Pistons, rods, and cylinder walls are at risk if timing adjustments exceed safe limits.

Preventative Measures to Maintain Reliability

- Use High-Octane Fuel

- Higher-octane fuel is more resistant to detonation, making it essential for advanced timing setups.

- Turbocharged 2JZ engines benefit significantly from premium fuel, especially at high boost levels.

- Monitor Knock Levels

- A knock sensor is a vital tool for detecting detonation. Use it during both tuning and regular operation.

- Some aftermarket ECUs can automatically adjust timing to prevent knocking in real-time.

- Balance Air-Fuel Ratios

- Advanced timing often necessitates richer air-fuel mixtures to prevent excessive heat buildup.

- Wideband oxygen sensors are invaluable for maintaining optimal ratios during tuning.

- Upgrade Cooling Systems

- Advanced timing increases engine temperatures, so a robust cooling system is critical. Consider:

- High-capacity radiators.

- Upgraded intercoolers for turbocharged models.

- Engine oil coolers to manage thermal stress.

- Advanced timing increases engine temperatures, so a robust cooling system is critical. Consider:

- Limit Timing Advance

- Incremental adjustments are key. Avoid large timing changes without thorough testing.

- Turbocharged engines, in particular, may require retarded timing under high boost to avoid excessive cylinder pressures.

- Regular Maintenance

- Perform routine checks on spark plugs, ignition coils, and timing components. Worn or failing parts can lead to erratic timing and poor performance.

- Ensure the timing belt and tensioner are in excellent condition to prevent timing drift.

Dynamic Timing Management with Aftermarket ECUs

Modern aftermarket ECUs (e.g., Link ECU, Haltech) offer advanced features to enhance reliability during tuning:

- Real-Time Knock Control: Automatically adjusts timing to prevent detonation.

- Temperature Compensation: Modifies timing based on intake air or coolant temperatures.

- Boost-Specific Timing Maps: Allows different timing settings for varying boost levels, ensuring safe operation at all power levels.

Signs of Unsafe Timing

It’s essential to recognize symptoms of unsafe timing before they escalate into major issues:

- Knocking or Pinging Sounds: Indicates detonation, especially under load or at high RPMs.

- Erratic Performance: Sudden power loss, misfires, or hesitation during acceleration.

- Elevated Exhaust Gas Temperatures (EGTs): A warning sign of overly advanced timing.

- Engine Overheating: Advanced timing increases combustion heat, which can overwhelm the cooling system.

Case Study: Safe Timing on a High-Performance 2JZ-GTE

Scenario: A tuner working on a 2JZ-GTE running 20 PSI of boost aims for maximum power without compromising reliability.

- Setup: High-octane fuel, upgraded cooling system, and forged internals.

- Approach: Timing is advanced incrementally during dyno testing, with knock sensors and wideband oxygen sensors providing feedback.

- Outcome: The tuner achieves a 10% power gain while maintaining safe engine temperatures and zero knock, thanks to careful calibration and high-quality components.

Checklist for Reliable Timing Tuning

- ✅ Use premium fuel to support advanced timing.

- ✅ Monitor knock and adjust timing dynamically.

- ✅ Ensure cooling systems are robust and effective.

- ✅ Incrementally advance timing with regular testing.

- ✅ Conduct regular maintenance on ignition and timing components.

By prioritizing reliability in your timing adjustments, you can safely extract impressive performance from your 2JZ engine without risking its longevity. This balance is what separates professional-grade tuning from reckless experimentation.

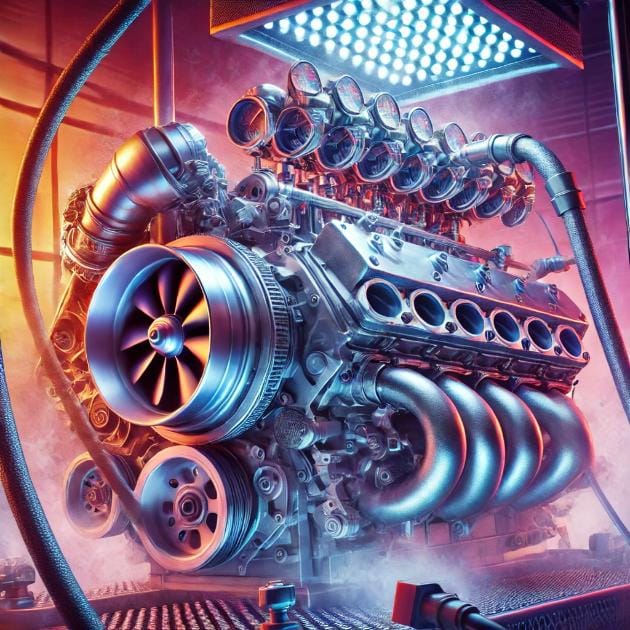

Timing Adjustment for Forced Induction (Turbocharged Engines)

Turbocharged engines, like the 2JZ-GTE, present unique challenges and opportunities when it comes to ignition timing adjustments. The introduction of forced induction dramatically increases cylinder pressures and temperatures, requiring precise timing strategies to optimize performance while preventing engine damage.

Why Timing is Critical for Turbocharged Engines

The addition of boost increases the air density and fuel mixture in the combustion chamber, creating higher power potential. However, it also makes the engine more prone to detonation, particularly if the ignition timing is too advanced. Proper timing adjustment is essential to harness the power of forced induction safely.

Key Considerations for Timing in Forced Induction Engines:

- Boost Levels: Higher boost pressures require more conservative timing to avoid excessive cylinder pressures.

- Fuel Quality: High-octane fuels are necessary to resist detonation under boosted conditions.

- Air-Fuel Ratio: A richer mixture helps reduce combustion temperatures and stabilize ignition timing.

Steps to Adjust Timing for Turbocharged 2JZ Engines

- Set Base Timing

- Begin with the factory-recommended base timing settings as a reference point.

- Lock the ECU timing (if applicable) to ensure accuracy during adjustments.

- Create a Boost-Specific Timing Map

- Use ECU tuning software to develop a timing map that varies based on boost levels.

- Gradually retard timing as boost pressure increases to manage cylinder pressures.

- Monitor Knock Levels

- Utilize knock sensors to detect early signs of detonation.

- Adjust timing incrementally to avoid knocking while maximizing power output.

- Use Dyno Testing

- Conduct dyno runs at various boost levels to identify the optimal timing settings for different load conditions.

- Record power and torque outputs, along with exhaust gas temperatures, to ensure safe operation.

- Incorporate Safety Features

- Enable features like boost cut and timing retard on knock detection to protect the engine from damage.

- Consider integrating real-time data logging to monitor engine performance during testing.

Timing Strategies for Specific Scenarios

- Low Boost (Up to 10 PSI)

- Timing can be advanced slightly to improve throttle response and power.

- Detonation risk is lower at this level, but it’s still important to monitor knock levels.

- Moderate Boost (10–20 PSI)

- Retard timing incrementally as boost increases to manage cylinder pressures.

- A balance between power and safety is critical at this stage.

- High Boost (20+ PSI)

- Timing should be retarded significantly under high boost to prevent detonation.

- Use high-octane fuel and upgraded cooling systems to mitigate the risks of excessive heat and pressure.

Case Study: Optimizing Timing on a High-Boost 2JZ-GTE

Scenario: A 2JZ-GTE running 25 PSI of boost with a precision turbo and upgraded internals.

- Approach: The tuner starts with conservative timing and gradually increases advance during dyno testing. Knock sensors and wideband oxygen sensors are used to fine-tune the timing map.

- Outcome: Power output increases by 15% with zero knock detected, thanks to a carefully managed timing strategy and high-octane fuel.

Tools for Boost Timing Optimization

- Aftermarket ECUs: Products like Haltech and Link ECU offer advanced timing control and data logging.

- Wideband Oxygen Sensors: Critical for monitoring air-fuel ratios under varying load conditions.

- Knock Monitors: Provide real-time feedback on detonation risk, allowing for immediate adjustments.

Common Pitfalls to Avoid

- Excessive Timing Advance: Leads to detonation and potential engine damage.

- Neglecting Fuel Quality: Using low-octane fuel under high boost increases the risk of knocking.

- Ignoring Cooling Needs: Turbocharged engines generate significant heat, making upgraded cooling systems essential.

Balancing Power and Safety

When adjusting timing for a turbocharged 2JZ engine, the key is finding the balance between pushing performance limits and maintaining engine reliability. Small, incremental changes supported by thorough testing will yield the best results.

Advanced Tools and Techniques for Precise Tuning

To fully unlock the potential of the 2JZ engine, precise tuning tools and advanced techniques are essential. Modern technology enables tuners to make accurate adjustments, monitor critical parameters, and optimize ignition timing with a level of precision that was once unattainable. This section explores the tools, techniques, and methodologies that can elevate your tuning process.

Essential Tools for Advanced Timing Tuning

- Aftermarket Engine Control Units (ECUs)

- Popular Options: Haltech, Link ECU, AEM Infinity, and Motec.

- Features:

- Customizable ignition timing maps.

- Real-time data logging and analysis.

- Advanced safety features like knock detection and boost-specific timing control.

- Advantages: Provide unparalleled flexibility for tuning forced induction and naturally aspirated engines.

- Wideband Oxygen Sensors

- Purpose: Monitor air-fuel ratios (AFR) to ensure the engine operates within safe parameters.

- Applications: Helps maintain the ideal mixture for combustion, critical when advancing timing.

- Popular Models: Innovate LC-2 and AEM X-Series.

- Knock Sensors and Monitors

- Purpose: Detect detonation in real-time, enabling precise timing adjustments.

- Advanced Tools: J&S Safeguard and Plex Knock Monitor provide detailed feedback to prevent engine damage.

- Dyno Machines

- Purpose: Test engine performance under controlled conditions to measure power, torque, and exhaust gas temperatures (EGT).

- Applications: Fine-tune ignition timing for maximum performance without risking engine safety on the road.

- Data Logging Tools

- Purpose: Record engine parameters like RPM, boost pressure, AFR, and knock levels during test runs.

- Examples: OBD-II-based loggers or integrated ECU logging capabilities.

Techniques for Precise Timing Adjustments

- Boost-Specific Timing Maps

- Create timing maps that dynamically adjust based on boost pressure.

- Retard timing under high boost to avoid excessive cylinder pressures while advancing under low boost for responsiveness.

- Real-Time Knock Control

- Utilize ECUs that adjust timing dynamically based on knock sensor feedback.

- This ensures safe operation even in unpredictable conditions like sudden temperature changes or fuel quality variations.

- Adaptive Timing Strategies

- Use temperature and load-based timing adjustments to optimize performance across all driving conditions.

- For example, retard timing slightly at high intake air temperatures to avoid detonation.

- Dyno Tuning Methodology

- Incrementally adjust ignition timing and monitor the effects on power and torque curves.

- Use EGT and AFR data to ensure combustion efficiency and safety.

- Fuel Compatibility Testing

- Test various fuel types to find the best match for your timing setup. High-octane fuels allow more aggressive timing, while lower-octane fuels require conservative adjustments.

Leveraging Software for Advanced Tuning

- ECU Tuning Software

- Examples: Haltech ESP, Link G4+, and Motec M1 Tune.

- Features include user-friendly interfaces, 3D timing map visualization, and real-time parameter adjustments.

- Simulation Tools

- Use simulation software to model timing adjustments before making physical changes.

- Benefits: Save time, reduce risk, and plan optimal timing strategies.

- Cloud-Based Data Sharing

- Share timing maps and tuning data with other professionals or communities to refine your approach.

Case Study: Advanced Tuning with Haltech Elite ECU

Scenario: A tuner works on a 2JZ-GTE engine running 18 PSI boost.

- Tools Used: Haltech Elite ECU, wideband oxygen sensor, and Plex Knock Monitor.

- Approach:

- The tuner creates a boost-specific timing map.

- Real-time knock control is enabled to dynamically adjust timing under high load.

- Dyno testing reveals a safe timing advance of 3° in the midrange, resulting in a 10% power increase.

- Outcome: The engine operates smoothly, with no knock detected, and significant performance gains are achieved.

Best Practices for Advanced Tuning

- Start Conservatively: Always begin with factory timing settings and make small, incremental changes.

- Prioritize Safety: Monitor knock, AFR, and EGT throughout the tuning process.

- Document Everything: Keep detailed records of all timing maps, adjustments, and results for future reference.

- Leverage Expertise: Collaborate with experienced tuners or use community forums to refine your techniques.

Avoiding Common Pitfalls

- Overreliance on Software: Always validate timing changes with real-world testing.

- Neglecting Maintenance: Ensure ignition components are in excellent condition before tuning.

- Skipping Diagnostics: Failing to address pre-existing issues can compromise tuning results.

With the right tools and techniques, precise tuning of ignition timing on a 2JZ engine becomes a systematic and reliable process. Advanced technologies like programmable ECUs and knock monitoring systems empower tuners to push the limits of performance while maintaining safety and reliability.

Troubleshooting Timing Issues

Even with careful tuning and advanced tools, timing issues can arise during the process of optimizing a 2JZ engine. Understanding the common symptoms of timing problems and knowing how to troubleshoot them is crucial for maintaining performance and avoiding costly engine damage.

Common Symptoms of Timing Issues

- Knocking or Pinging Sounds

- Detonation occurs when the air-fuel mixture ignites prematurely, causing a metallic knocking sound.

- Often a result of overly advanced timing or insufficient fuel octane.

- Misfires

- Irregular ignition timing can lead to incomplete combustion, causing rough idling or hesitation under acceleration.

- Poor Performance

- Incorrect timing may reduce power and throttle response, particularly in the mid-to-high RPM range.

- Overheating

- Advanced timing increases combustion heat, which can strain the cooling system and raise engine temperatures.

- Hard Starting

- Timing that is too advanced or retarded can make it difficult for the engine to start, especially in colder conditions.

Step-by-Step Troubleshooting Guide

- Check Base Timing

- Use a timing light to verify that the base timing matches the factory specifications.

- For ECU-controlled 2JZ engines, ensure the ECU is in diagnostic mode to lock timing during testing.

- Inspect Timing Components

- Check the timing belt for proper alignment and tension. A worn or misaligned belt can cause timing drift.

- Inspect the crankshaft and camshaft position sensors for damage or improper connections.

- Monitor Knock Sensor Data

- If knocking is detected, reduce timing advance and verify fuel octane compatibility.

- Ensure the knock sensor is functioning correctly and providing accurate feedback to the ECU.

- Analyze Air-Fuel Ratios

- Use a wideband oxygen sensor to verify that the engine is running at the optimal air-fuel ratio.

- Adjust fuel maps if needed to prevent lean conditions, which increase detonation risk.

- Test Under Different Loads

- Timing issues may only appear under specific load conditions (e.g., high boost, full throttle).

- Conduct road or dyno tests to replicate these conditions and identify problematic timing zones.

- Review ECU Timing Maps

- Check for errors or conflicts in the timing map, especially if the engine is using an aftermarket ECU.

- Retard timing in zones where knocking or misfires occur.

- Check Ignition Components

- Inspect spark plugs, ignition coils, and wiring for wear or damage. Faulty components can cause irregular ignition timing.

- Reset and Re-Calibrate

- If troubleshooting does not resolve the issue, reset the ECU to factory settings and start over with a clean timing map.

- Re-calibrate sensors like the crankshaft position sensor if necessary.

Advanced Troubleshooting with Tools

- Data Logging

- Use ECU logging features to capture timing, knock, AFR, and boost data during runs.

- Analyze trends and pinpoint specific RPM or load zones causing issues.

- Cylinder-by-Cylinder Analysis

- Advanced tuning tools allow for individual cylinder timing adjustments.

- Identify if a specific cylinder is causing issues due to uneven combustion or ignition faults.

- Dyno Testing

- Replicate real-world conditions on a dynamometer to safely test and adjust timing under controlled conditions.

Case Study: Troubleshooting Knock Issues on a 2JZ-GTE

Scenario: A 2JZ-GTE engine running 18 PSI of boost experiences knocking under mid-to-high RPM conditions.

- Initial Observations: The knock occurs consistently at 4,500–6,000 RPM.

- Steps Taken:

- The tuner retards ignition timing by 2° in the affected RPM range.

- AFR is adjusted from 12.5:1 to 11.8:1 to provide a richer mixture.

- High-octane fuel (98 RON) is used to further reduce detonation risk.

- Outcome: Knocking is eliminated, and the engine delivers smooth, reliable power throughout the RPM range.

Preventative Measures

- Regular Maintenance

- Keep the timing belt, ignition components, and sensors in optimal condition.

- High-Octane Fuel

- Always use the appropriate fuel grade for your tuning setup.

- Incremental Adjustments

- Make small timing changes and test thoroughly before moving to the next adjustment.

- Data-Driven Tuning

- Rely on real-time data from sensors and ECU logging to make informed decisions.

By understanding and addressing timing issues promptly, you can ensure consistent performance and avoid unnecessary engine wear or damage. Troubleshooting is an integral part of the tuning process, and a systematic approach will help you overcome challenges efficiently.

Lessons from Professional Tuners

Professional tuners have honed their craft through years of experience, working on countless 2JZ engines and perfecting the art of ignition timing adjustment. Learning from their successes—and their mistakes—can save time, effort, and money while improving your own tuning results.

Best Practices from Professional Tuners

- Start Conservatively

- Always begin with the factory-recommended timing settings as a baseline.

- Incrementally advance or retard timing in small steps, testing at each stage to gauge the impact.

- Monitor Data Relentlessly

- Utilize ECU logging tools, wideband oxygen sensors, and knock monitors to gather detailed data during tuning.

- Cross-reference engine parameters like AFR, knock levels, and exhaust gas temperatures to identify safe timing zones.

- Optimize Timing for Specific Scenarios

- For naturally aspirated 2JZ-GE engines, focus on throttle response and mid-range power.

- For turbocharged 2JZ-GTE engines, prioritize timing adjustments at high RPM and under boost conditions.

- Prioritize Safety Over Power

- Resist the temptation to over-advance timing for marginal power gains.

- Maintain a buffer to prevent detonation, especially under extreme operating conditions.

Common Mistakes to Avoid

- Skipping Pre-Tuning Preparation

- Neglecting to check timing belt alignment, spark plugs, or fuel quality can lead to inaccurate adjustments and engine damage.

- Relying Solely on Factory Settings

- While factory timing is designed for reliability, it doesn’t account for performance tuning potential. Adjustments are essential for optimizing power.

- Ignoring Knock Indicators

- Failing to address knock detection can result in severe engine damage. Always investigate and resolve knock issues before proceeding.

- Overlooking Fuel Compatibility

- Using low-octane fuel with advanced timing or high boost can lead to catastrophic detonation. Stick to premium fuel for tuned engines.

Insights from Tuning Experts

- On Timing Balance

- “The key to great tuning is balance. Advance just enough to make power but not so much that you risk detonation. It’s a fine line, and every engine is unique.”

— Jason Black, Professional Tuner

- “The key to great tuning is balance. Advance just enough to make power but not so much that you risk detonation. It’s a fine line, and every engine is unique.”

- On ECU Utilization

- “A good ECU is your best friend. With programmable timing maps and real-time monitoring, you can achieve precision that’s impossible with stock setups.”

— Laura Kim, ECU Specialist

- “A good ECU is your best friend. With programmable timing maps and real-time monitoring, you can achieve precision that’s impossible with stock setups.”

- On Incremental Adjustments

- “Don’t rush. Small, consistent adjustments and thorough testing are the safest way to maximize performance. There are no shortcuts.”

— Alex Torres, Engine Builder

- “Don’t rush. Small, consistent adjustments and thorough testing are the safest way to maximize performance. There are no shortcuts.”

Case Study: A Professional Approach to 2JZ Timing Tuning

Scenario: A tuning shop works on a 2JZ-GTE engine with upgraded turbos and intercooling, aiming for 800 horsepower.

- Setup: Haltech ECU, 100-octane fuel, and knock sensors.

- Steps Taken:

- Timing is advanced incrementally during dyno testing, with AFR adjusted to 11.5:1 under full load.

- High boost zones (25+ PSI) are mapped with retarded timing to prevent detonation.

- Knock sensors are monitored continuously, and safety limits are enabled in the ECU.

- Outcome: The engine produces 815 horsepower with consistent reliability, demonstrating the importance of methodical adjustments and advanced tools.

Tips for DIY Tuners

- Invest in Tools: A quality timing light, ECU software, and wideband oxygen sensor are essential for precise tuning.

- Leverage Community Resources: Online forums, tuning guides, and workshops can provide invaluable advice and support.

- Practice Patience: Mastery takes time. Start small, experiment, and learn from each adjustment.

Learning from Mistakes

Professional tuners often stress that the best lessons come from failures. Documenting your process and analyzing errors is just as important as celebrating successes. Mistakes like advancing timing too quickly or ignoring knock can teach valuable lessons that improve your future tuning efforts.

Conclusion

The 2JZ engine is a powerhouse with immense potential, and ignition timing plays a pivotal role in unlocking its performance while maintaining reliability. From understanding the basics of timing to employing advanced tools and techniques, every aspect of tuning requires precision and careful planning.

Key Takeaways

- Ignition Timing’s Impact: Proper ignition timing improves power, efficiency, and durability, while incorrect adjustments can lead to severe issues like detonation and overheating.

- Tools and Techniques: Leveraging modern tools like aftermarket ECUs, wideband oxygen sensors, and knock monitors ensures precise timing adjustments.

- Balancing Performance and Safety: Incremental adjustments, high-quality fuel, and robust cooling systems help achieve the perfect balance.

- Continuous Learning: Lessons from professional tuners, case studies, and troubleshooting strategies provide invaluable insights for every tuning enthusiast.

Ignition timing tuning is both an art and a science. With the right tools, knowledge, and patience, you can transform your 2JZ engine into a performance masterpiece. Whether you’re building a daily driver or a track-focused beast, the strategies outlined in this guide will help you achieve your goals while preserving your engine’s reliability.

Share Your Journey

Have you tuned your 2JZ engine’s ignition timing? Share your experiences, tips, or challenges in the comments below! Let’s build a community of tuners who inspire and support one another.

If you’re ready to take the next step in tuning your 2JZ engine, explore our other guides on performance upgrades, ECU programming, and maintenance tips. Stay tuned for more content tailored to maximizing your engine’s potential.

Frequently Asked Questions (FAQ)

What is ignition timing, and why is it important for a 2JZ engine?

Ignition timing refers to the exact moment when the spark plug ignites the air-fuel mixture inside the engine’s combustion chamber. In a 2JZ engine, proper ignition timing is critical because:

- It maximizes power output by ensuring the combustion process occurs at the optimal time relative to piston position.

- It improves fuel efficiency by utilizing the energy in the fuel more effectively.

- It prevents knocking and detonation, which can damage engine components, especially in high-performance or turbocharged setups like the 2JZ-GTE.

How do I adjust the ignition timing on a 2JZ engine?

Adjusting ignition timing on a 2JZ engine depends on the model (VVT-i or non-VVT-i) and whether you’re using stock or aftermarket components:

- Non-VVT-i Models:

- Use a timing light to observe timing marks on the crankshaft pulley.

- Loosen the distributor bolts and rotate the distributor to advance or retard timing until it aligns with the desired setting (e.g., 10° BTDC).

- VVT-i Models:

- Adjust timing through the ECU using tuning software (e.g., Haltech or Link ECU).

- Lock the ECU in diagnostic mode to set base timing, then refine it using timing maps.

Always verify adjustments with real-time data, such as knock sensor feedback and air-fuel ratios.

What are the signs of incorrect ignition timing in a 2JZ engine?

Incorrect ignition timing can lead to several performance issues, including:

- Knocking or Pinging Sounds: A metallic knocking sound caused by detonation when timing is too advanced.

- Loss of Power: Poor combustion due to overly retarded timing, resulting in reduced throttle response and lower horsepower.

- Misfires: Irregular ignition can cause rough idling or hesitation during acceleration.

- Overheating: Advanced timing generates excessive combustion heat, which can overwhelm the cooling system.

- Difficulty Starting: Incorrect base timing can make it hard to start the engine, especially in cold conditions.

Can advancing ignition timing damage my 2JZ engine?

Advancing ignition timing can improve power and throttle response, but it must be done cautiously:

- If timing is advanced too far, the air-fuel mixture ignites prematurely, leading to detonation (knock).

- Detonation creates extreme pressure spikes that can damage pistons, rods, and cylinder walls.

- Turbocharged engines (like the 2JZ-GTE) are particularly sensitive to advanced timing under high boost levels, as cylinder pressures are already elevated.

To prevent damage: - Use high-octane fuel to resist detonation.

- Monitor knock sensors during tuning.

- Retard timing slightly under high load or boost conditions.

What tools do I need for precise timing adjustments on a 2JZ engine?

To accurately set and adjust ignition timing on a 2JZ engine, you’ll need the following tools:

- Timing Light: To measure and adjust base timing. Look for one with an adjustable advance feature.

- Aftermarket ECU: Programmable ECUs like Haltech or Link allow for precise control of timing maps.

- Wideband Oxygen Sensor: Monitors air-fuel ratios to ensure safe combustion.

- Knock Monitor: Detects detonation in real-time to avoid damaging the engine.

- Dyno Machine: Measures power output and helps refine timing under controlled conditions.

- Data Logging Software: Records engine parameters like RPM, AFR, and knock levels during test runs for analysis.

These tools are essential for tuning both naturally aspirated and turbocharged 2JZ engines safely and effectively.