ECM connectors are critical components that ensure the efficient operation of your 2JZ engine by facilitating communication between the Engine Control Module (ECM) and various sensors and actuators. Proper handling and testing of these connectors are essential to maintain optimal engine performance. For 2JZ engine enthusiasts, understanding how to handle and test ECM connectors is crucial to avoid electrical issues that could lead to engine problems.

In this comprehensive guide, we will explore the importance of ECM connectors, delve into common issues and their causes, and provide a detailed step-by-step approach to handling and testing these connectors. By understanding and implementing these practices, you can ensure your 2JZ engine remains in top condition.

Understanding ECM Connectors

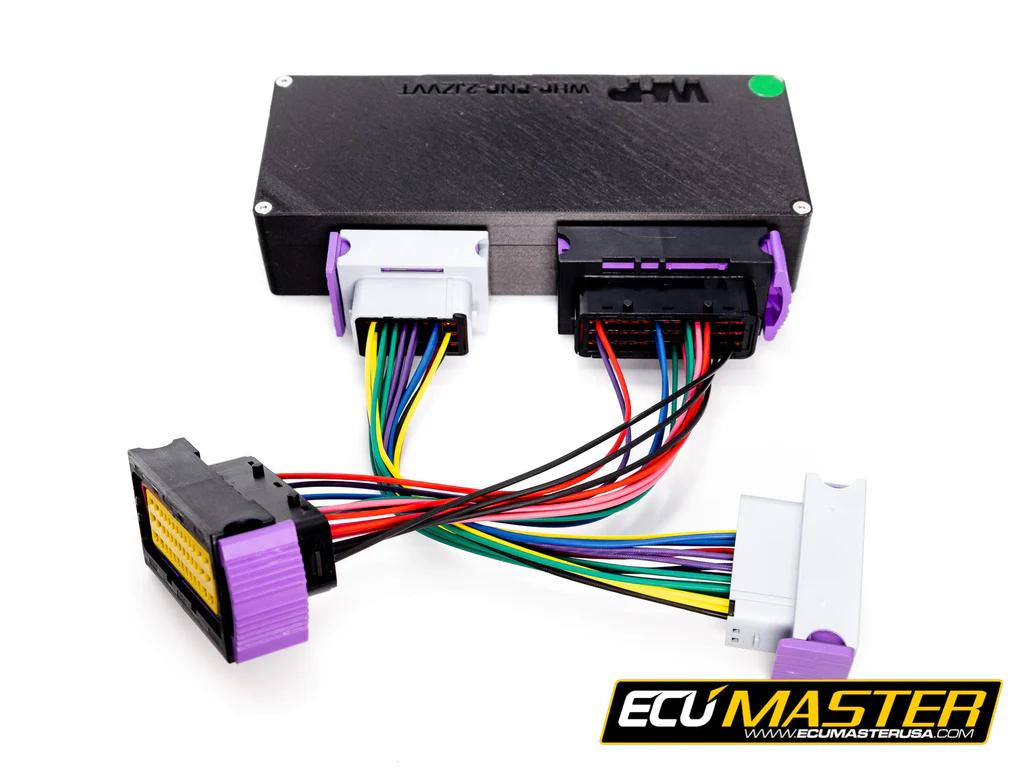

ECM connectors in the 2JZ engine are designed to provide secure electrical connections between the ECM and various engine sensors and actuators. These connectors ensure that the ECM receives accurate data and can send appropriate commands to control engine functions.

Key Components of ECM Connectors in the 2JZ Engine:

- Connectors: Securely attach wires to the ECM.

- Pins: Provide electrical contact points within the connectors.

- Seals: Prevent moisture and contaminants from entering the connectors.

- Wiring Harness: Connects sensors and actuators to the ECM.

Importance of Proper Handling and Testing of ECM Connectors:

- Ensures reliable communication between the ECM and engine components.

- Prevents electrical issues such as short circuits and poor connections.

- Maintains optimal engine performance and prevents drivability issues.

Understanding the components and functions of ECM connectors is crucial for accurate diagnostics and effective maintenance.

Common ECM Connector Issues

ECM connector issues can lead to various engine performance problems. Recognizing the symptoms and understanding their causes can help in diagnosing and resolving these problems effectively.

Symptoms of ECM Connector Problems:

- Check Engine Light: Illuminates due to diagnostic trouble codes (DTCs) related to ECM connector issues.

- Intermittent Engine Performance: Inconsistent power delivery or engine stalling.

- Electrical Failures: Non-functional sensors or actuators.

- Poor Engine Performance: Lack of power, rough idling, or misfires.

- Increased Fuel Consumption: Noticeable drop in fuel efficiency.

Common Causes of ECM Connector Failures:

- Physical Damage: Connectors can be damaged by heat, abrasion, or impact.

- Corrosion: Moisture can cause corrosion at connectors and terminals.

- Poor Connections: Loose or poorly connected pins can cause intermittent issues.

- Contamination: Dirt and debris can infiltrate connectors and disrupt electrical signals.

Impact on Engine Performance:

- Reduced Power: Incorrect data processing can lead to improper fuel and ignition settings.

- Engine Stalling: Irregular ECM connections can cause the engine to stall unexpectedly.

- Increased Emissions: Improper engine control results in higher emissions, failing emission tests.

By understanding these common ECM connector issues and their impacts, you can effectively diagnose and address engine control circuit problems.

Handling and Testing ECM Connectors

Proper handling and testing of ECM connectors involve a systematic approach, using specific tools and techniques to identify and resolve issues. Here is a step-by-step guide to handling and testing ECM connectors in the 2JZ engine.

Tools Required:

- Multimeter: Tests electrical components and wiring.

- Contact Cleaner: Cleans connectors and removes contaminants.

- Service Manual: Provides specific testing procedures and specifications.

Step-by-Step Guide:

- Preparation:

- Ensure the engine is off and the key is removed from the ignition.

- Gather all necessary tools, including the multimeter and contact cleaner.

- Visual Inspection:

- Locate the ECM connectors and inspect them for any signs of damage, corrosion, or contamination.

- Ensure all connectors are securely attached and free from debris.

- Cleaning the Connectors:

- Use contact cleaner to clean the connectors and remove any dirt, oil, or corrosion.

- Allow the connectors to dry completely before proceeding.

- Testing the Connectors with a Multimeter:

- Set the multimeter to measure continuity or resistance (Ω).

- Connect the multimeter probes to the appropriate terminals as specified in the service manual.

- Test for continuity and resistance in the connectors to identify any poor connections or breaks.

- Repairing or Replacing Connectors:

- If any connectors are damaged or corroded, use appropriate tools to repair or replace them.

- Ensure all repairs are secure and match the specifications in the service manual.

- Reconnect the cleaned and tested connectors to the ECM.

Interpreting Testing Results:

- Normal Readings: Indicate the ECM connectors and their connections are functioning correctly.

- Abnormal Readings: Suggest an issue that needs to be addressed, such as a poor connection, broken pin, or contaminated connector.

By following these handling and testing procedures, you can accurately identify and resolve ECM connector problems, ensuring your 2JZ engine performs optimally.

Conclusion

In summary, proper handling and testing of ECM connectors is essential for maintaining the performance and reliability of your 2JZ engine. By understanding the components, common issues, and diagnostic procedures, you can effectively address any problems and ensure your engine runs smoothly.

If you suspect any issues with your ECM connectors, perform a detailed diagnostic using the steps outlined in this guide. Regular maintenance and timely repairs will help maintain the performance and longevity of your 2JZ engine.

Frequently Asked Questions (FAQ)

What are ECM connectors and why are they important?

ECM connectors provide secure electrical connections between the ECM and various engine sensors and actuators, ensuring reliable communication and control.

How can I test ECM connectors for issues?

Use tools such as a multimeter to test the connectors for continuity and resistance. Follow the step-by-step guide provided in this article.

What tools do I need for handling and testing ECM connectors?

You will need a multimeter, contact cleaner, and the service manual.

Can I repair ECM connectors myself?

Yes, with the proper tools and knowledge, you can repair ECM connectors yourself. Follow the steps provided in this guide and refer to the service manual.

How often should I check my ECM connectors?

Regular diagnostics should be performed during routine maintenance, such as every oil change or every 10,000 miles, to catch issues early and maintain engine health.