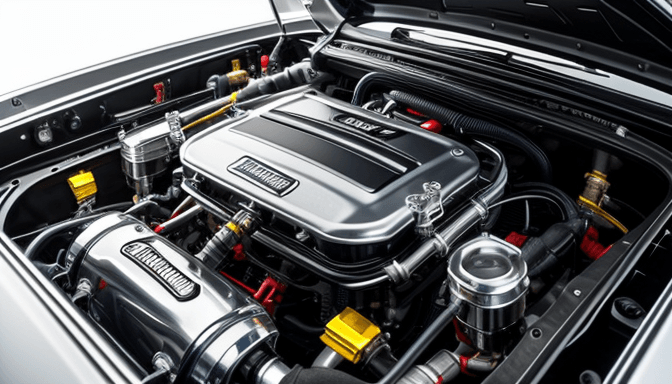

Upgrading the fuel pressure regulator (FPR) and return system on a 2JZ engine isn’t just about swapping parts—it’s about understanding the heartbeat of your fuel delivery system. Imagine your engine as a finely tuned orchestra, where the fuel pressure regulator acts like the conductor, keeping every note in harmony. Without a solid upgrade, your engine might miss a beat, especially when pushed hard under high-performance conditions.

When you start tweaking your 2JZ for more power, the stock fuel system often struggles to keep up. The factory FPR and return lines were designed for everyday driving, not for the bursts of fuel demand that come with boosting or running alternative fuels like E85. If you don’t upgrade, you risk uneven fuel pressure, which leads to lean conditions, engine hesitation, or worse—damage.

So, what’s the secret sauce? It’s all about matching the right regulator with a properly sized return system. The return system plays a vital role in maintaining steady fuel pressure by sending excess fuel back to the tank. Think of it as a pressure relief valve that keeps the system from going haywire. Upgrading this system means choosing thicker, high-quality return lines and a regulator that can handle the flow without faltering.

But here’s a little insider tip: upgrading isn’t just about throwing in the fanciest parts. It’s about fitting them correctly and tuning the system to your unique setup. An aftermarket FPR without the right return line or improper installation can cause more headaches than benefits. It’s like giving a racecar a turbo but forgetting to upgrade the fuel lines—you’ll choke the performance potential.

In my experience working with 2JZ builds, the best upgrades come from understanding your engine’s needs and matching components accordingly. Whether you’re aiming for a street-friendly setup or a full-blown track monster, the fuel pressure regulator and return system are critical pieces you can’t overlook. They ensure your engine drinks just the right amount of fuel—no more, no less—keeping it happy and healthy under all conditions.

Ready to dive deeper? Let’s break down why the fuel pressure regulator matters, the differences between return and returnless systems, and how to pick the right parts for your 2JZ. Trust me, once you get this right, your engine will thank you with smoother power delivery and fewer surprises on the road or track.

Why the Fuel Pressure Regulator Matters in High-Power Builds

When you’re pushing a 2JZ engine beyond its stock limits, every detail counts—especially the fuel pressure regulator (FPR). Think of the FPR as the gatekeeper of your fuel system. It makes sure your engine gets just the right amount of fuel, no more, no less. Sounds simple, right? But in high-power builds, this tiny component becomes a linchpin for performance and reliability.

Imagine trying to fill a glass with water from a fire hose. Without control, you’d either flood the glass or barely fill it. That’s exactly what happens if your fuel pressure isn’t steady. Too much pressure can flood the engine, causing poor combustion and even damage. Too little, and your engine starves, leading to hesitation or worse—knocking under boost. The FPR keeps this balance in check, adjusting fuel flow to match your engine’s demands.

High-power engines don’t just run harder; they demand consistency under extreme conditions. When boost climbs, fuel needs spike. The stock regulator often can’t keep pace, resulting in pressure fluctuations that kill performance. Upgrading your FPR means you’re giving your engine a steady, reliable fuel supply. It’s the difference between a smooth, aggressive pull and a choppy, unpredictable ride.

Here’s a little secret from my own experience: when I first tuned a turbo 2JZ, I ignored the fuel pressure regulator upgrade. The engine stumbled, and I couldn’t figure out why. Once I swapped in a quality adjustable regulator, everything changed. The power delivery smoothed out, and the engine responded like it was meant to. That’s the kind of impact a good FPR upgrade can have.

In short, the fuel pressure regulator is not just a part; it’s a key player in your engine’s fuel delivery team. Without it performing perfectly, your high-power build won’t reach its full potential. So, if you’re serious about boosting your 2JZ, don’t overlook this small but mighty component.

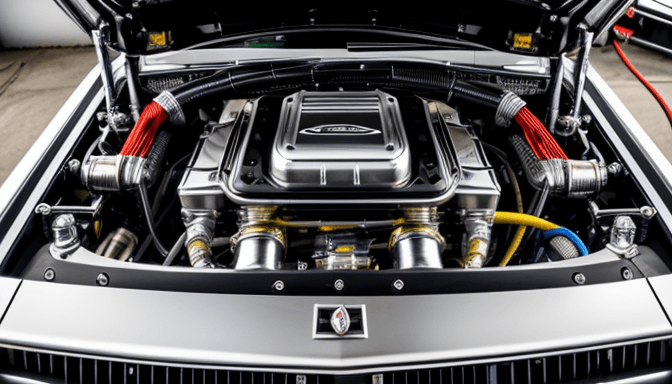

Return vs Returnless Systems: Understanding the Difference

When diving into the world of fuel systems for your 2JZ engine, one of the first questions you’ll face is: should you go with a return or a returnless fuel system? It might sound technical, but the difference boils down to how fuel pressure is controlled and managed. Imagine your fuel system as a busy highway. In a return system, the fuel flows from the pump, through the engine, and any extra fuel takes the exit ramp back to the tank. This constant loop keeps pressure steady, much like traffic moving smoothly with clear lanes and exits.

On the flip side, a returnless system is more like a one-way street. Fuel goes from the tank to the engine, and the pressure is controlled right at the pump, so there’s no fuel sent back. This design simplifies the plumbing and reduces the chance of leaks, but it demands more precise control from the pump and regulator. For high-performance builds, especially on a 2JZ where every drop counts, this difference can be huge.

Return systems are often favored in boosted or heavily tuned engines because they allow for better pressure regulation under varying loads. The fuel pressure regulator in a return setup can quickly adjust fuel flow, preventing lean conditions that could damage your engine. Think of it like having a skilled traffic cop directing cars to avoid jams during rush hour. However, the downside is the extra plumbing complexity and potential for leaks at the return lines.

Returnless systems, meanwhile, shine in simpler, lower-demand setups or where packaging space is tight. They reduce heat soak by keeping fuel in the tank cooler, which can be a subtle but important factor in performance. But if you push your 2JZ hard, the lack of a return line can sometimes mean slower response to sudden fuel demands, like a traffic light that’s a bit too slow changing.

Here’s a quick glance at the pros and cons:

| System Type | Pros | Cons |

|---|---|---|

| Return | Precise fuel pressure control, better for high boost, quick response | More complex plumbing, higher leak risk, potential heat soak |

| Returnless | Simpler setup, less plumbing, reduced heat soak | Less precise pressure control, slower response under load |

In the end, choosing between return and returnless systems depends on your build goals. If you want tight control over fuel delivery for a high-powered 2JZ, the return system often wins. But if you’re aiming for simplicity and reliability with moderate power, a returnless system might just do the trick. It’s like choosing the right tool for the job — knowing how each system behaves helps you avoid surprises down the road.

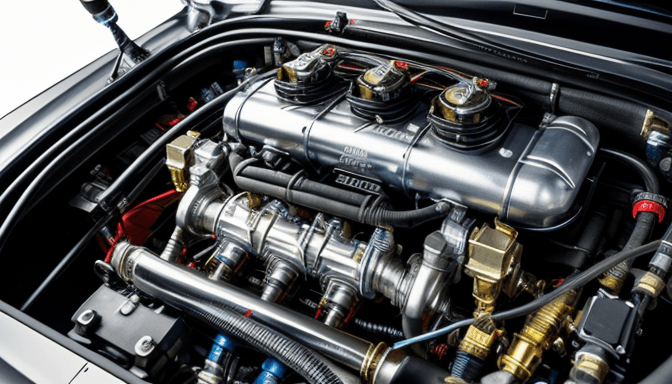

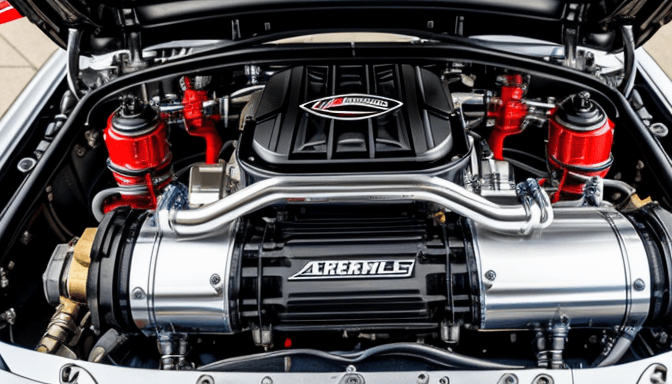

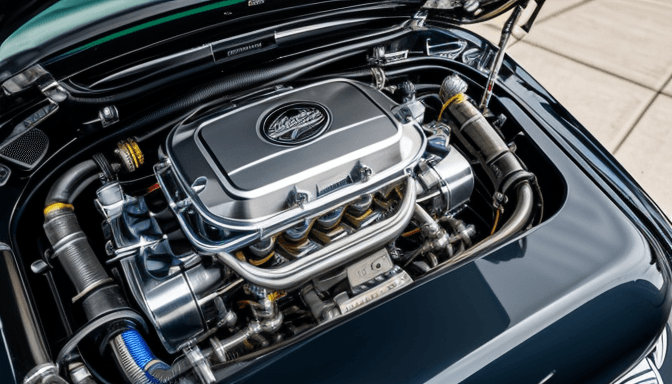

Top FPR Brands for 2JZ: Aeromotive, Radium, Fuelab

If you’re diving into upgrading your 2JZ’s fuel pressure regulator (FPR), you’ve probably noticed the market is flooded with options. But it’s not just about picking any brand—it’s about choosing one that fits your build’s needs, reliability, and ease of use. Three names keep popping up among 2JZ enthusiasts: Aeromotive, Radium, and Fuelab. Each brings something unique to the table, and understanding their strengths can save you headaches down the road.

Aeromotive is often the go-to for those who want rock-solid reliability paired with precision engineering. Their FPRs are known for consistent fuel pressure control, which is crucial when you’re pushing your 2JZ to higher boost levels or running alternative fuels like E85. What stands out is their modular design—making it easier to service or upgrade without tearing down your entire fuel system. Plus, Aeromotive regulators typically handle high flow rates, perfect for builds aiming for serious horsepower.

On the flip side, Radium Engineering offers a fresh take with innovative designs that blend performance and compactness. Their regulators often come with adjustable settings right out of the box, giving you more control over your fuel pressure without needing extra gadgets. Radium’s attention to detail means you’re less likely to run into fitment issues on the 2JZ platform, especially if you’re trying to keep things tidy under the hood. Their products also tend to be lighter, which might not sound like a big deal, but every bit counts when you’re chasing performance.

Then there’s Fuelab, a brand that’s carved its niche by focusing on durability and fuel system health. Their regulators are built to withstand harsh conditions, which is a blessing if you’re running a daily-driven turbo 2JZ or tackling track days. Fuelab’s strength lies in their ability to maintain stable fuel pressure over long periods, reducing the chance of lean conditions that could fry your engine. If you’ve ever dealt with inconsistent fuel delivery, Fuelab’s reputation for smooth operation might just be the peace of mind you need.

Here’s a quick rundown to help you weigh your options:

| Brand | Key Strength | Best For | Notable Feature |

|---|---|---|---|

| Aeromotive | Precision & Reliability | High-boost, E85 builds | Modular design, high flow capacity |

| Radium | Compact & Adjustable | Clean installs, street & track | Built-in adjustability, lightweight |

| Fuelab | Durability & Stability | Daily drivers, endurance runs | Consistent pressure over time |

Choosing between these brands isn’t about which one is “best” universally—it’s about what fits your specific goals. Are you chasing raw power? Aeromotive might be your friend. Want a neat, user-friendly setup? Radium could be the answer. Need something that won’t quit on you during long drives? Fuelab’s got your back. In any case, investing in a quality FPR means less stress, fewer surprises, and a smoother ride on your journey to unlocking your 2JZ’s potential.

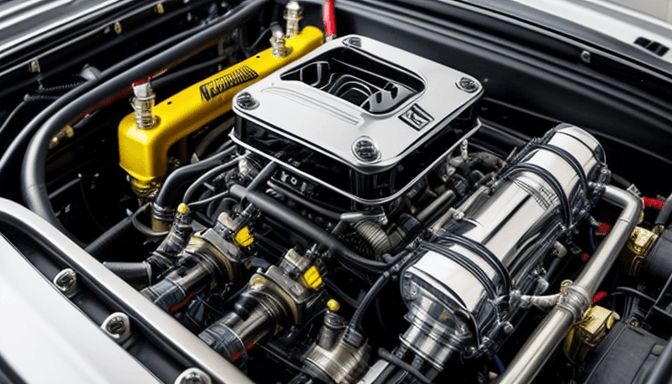

How to Adapt an Aftermarket Regulator to the Stock Fuel Rail

Adapting an aftermarket fuel pressure regulator (FPR) to your stock 2JZ fuel rail might sound tricky, but it’s totally doable with a bit of patience and the right approach. First off, remember that the stock fuel rail wasn’t originally designed with aftermarket regulators in mind. So, a little creativity and some careful modifications are part of the process. The key is to ensure a tight, leak-free connection while maintaining proper fuel flow. You don’t want your upgrade to cause headaches down the line, right?

Start by inspecting the stock fuel rail’s ports. Most 2JZ fuel rails have a factory FPR port, but the size and thread type may not match your new regulator. This is where adapters or custom fittings come in. Rather than forcing parts to fit, which can lead to leaks or damage, it’s smarter to source a quality adapter that matches both the regulator’s inlet and the rail’s outlet. These adapters often come in handy sizes like -6AN or -8AN fittings, which are common in aftermarket fuel systems.

Now, if you’re dealing with a regulator that requires a return line and your stock rail isn’t set up for one, you’ll need to add a return fitting. This might mean drilling and tapping the fuel rail, which sounds scarier than it is. Just take your time, use the right tools, and double-check measurements before drilling. It’s like performing surgery: precision is everything. When in doubt, ask a seasoned mechanic or someone who’s done this mod before.

Once the fittings are in place, connect your fuel lines with high-quality braided hoses and clamps designed for fuel use. Avoid cheap rubber hoses here; they can swell or crack under pressure and heat. The goal is a system that holds steady under boost and high fuel demand without any hiccups.

Finally, don’t forget to test everything thoroughly. Before firing up the engine, pressurize the system and check for leaks. A drop of soapy water on connections can reveal sneaky bubbles indicating a leak. Fix those before moving on. Also, keep in mind that tuning your fuel pressure after installation is critical. Your new regulator might change the baseline pressure, so adjust accordingly to keep your engine happy and safe.

Adapting an aftermarket regulator to the stock fuel rail isn’t just about swapping parts; it’s about understanding how each component interacts. Think of it like upgrading a bike’s brakes—you want smoother stopping power without compromising safety. With the right mindset and attention to detail, your 2JZ’s fuel system will handle bigger demands with ease and reliability.

Setting Base Fuel Pressure for Boosted and E85 Applications

When it comes to tuning your 2JZ for boosted setups or running E85, setting the right base fuel pressure isn’t just a step in the process—it’s the foundation for everything that follows. Think of it like tuning a guitar before a big show; if your strings are off, the whole performance suffers. The fuel pressure regulator controls how much fuel reaches your engine, and getting this dialed in means smoother power delivery and fewer headaches down the road.

For boosted engines, the fuel system has to work harder. Boost increases the air entering the engine, so you need more fuel to keep the air-fuel ratio balanced. This usually means raising the base fuel pressure above the stock setting. But it’s not as simple as cranking it up and hoping for the best. Too high, and you risk flooding the engine or wasting fuel; too low, and you starve your engine when it demands more. A good rule of thumb is to increase the base pressure by about 1 psi for every pound of boost, but always double-check with your specific setup.

Switching to E85 adds another layer of complexity. E85 burns cooler and allows for more aggressive timing, but it also requires roughly 30% more fuel than gasoline. That means your base fuel pressure needs to be adjusted accordingly to keep your engine happy. Many tuners recommend bumping the base pressure by 30-40% when running E85, but again, it depends on your injectors and pump. The key is to avoid guessing—use a reliable fuel pressure gauge and monitor how your engine responds.

Here’s where things get interesting: combining boost and E85 means you’re juggling two variables at once. The base fuel pressure must be high enough to meet the increased fuel demand but stable enough to prevent pressure spikes that can confuse your fuel system. It’s a delicate dance, and small tweaks can make a big difference. Many enthusiasts find success by starting with a base pressure around 45-50 psi on E85 with moderate boost, then fine-tuning from there based on real-world driving and dyno results.

Remember, the goal isn’t just to set a number—it’s to create a consistent and reliable fuel supply that matches your engine’s needs under all conditions. Don’t be afraid to experiment a little, but always keep safety in mind. A well-set fuel pressure system is like a good teammate: it works quietly in the background, letting your 2JZ shine without drama.

Recommended Return Line Sizes and Materials

When it comes to upgrading your 2JZ’s fuel system, the return line might not get as much spotlight as the fuel rail or injectors, but trust me, it’s just as crucial. The return line’s job is to carry excess fuel back to the tank smoothly and efficiently. If this line is too narrow or made from the wrong material, you’re asking for trouble—pressure drops, leaks, or even fuel starvation under hard driving conditions. None of that sounds fun, right?

So, what size should your return line be? For most high-performance 2JZ builds, a diameter between 6 to 8 millimeters (around 3/8 to 5/16 inch) works well. This size strikes a balance—it’s wide enough to handle the fuel volume without causing bottlenecks, yet not so large that it becomes bulky or difficult to route in tight engine bays. Going smaller? You risk starving your engine during boost. Going bigger? You might face issues with fuel pooling or slower return flow, which can mess with pressure consistency.

Material choice is just as important as size. You want something that can handle heat, resist corrosion, and stay flexible enough for easy installation. Typically, PTFE-lined stainless steel braided hoses are the go-to for many enthusiasts. Why? Because they combine durability with excellent chemical resistance, meaning they won’t degrade when exposed to ethanol blends like E85 or high-octane race fuels. Plus, the stainless braid protects the hose from abrasion and heat, which is a big deal in a hot engine bay.

If you’re on a tighter budget or prefer a simpler setup, high-quality rubber fuel lines rated for high pressure and temperature can work—but make sure they’re specifically designed for fuel injection systems. Cheaper rubber hoses might swell or crack over time, leading to leaks or even dangerous fuel spills.

Here’s a quick rundown of what to consider:

- Diameter: Stick to 6-8mm for most builds.

- Material: PTFE-lined stainless steel braided hose for durability and safety.

- Compatibility: Ensure hoses are rated for your fuel type (gasoline, E85, etc.).

- Routing: Keep the line away from extreme heat sources and sharp bends.

Think of your return line like a highway for fuel. Too narrow, and you get traffic jams; too flimsy, and the road falls apart. Choosing the right size and material ensures your fuel system breathes easy, keeping your 2JZ running smooth and strong no matter how hard you push it.

Common Installation Mistakes and How to Avoid Fuel Leaks

When upgrading the fuel pressure regulator and return system on your 2JZ engine, fuel leaks are one of the most frustrating issues you can face. They don’t just cause messes; they can also lead to serious safety hazards. The truth is, many leaks come from simple mistakes that are easy to overlook if you’re in a rush or unfamiliar with the setup. For example, using the wrong type of thread sealant or over-tightening fittings can create tiny cracks or strip threads, which then become leak points. It’s like trying to seal a bucket with a patch that’s too small — no matter how much tape you use, water will find its way out.

Another common slip-up is ignoring the compatibility between fuel lines and fittings. Not all hoses handle high pressure or specific fuel types like E85 equally well. Imagine trying to fit a square peg into a round hole; it just won’t seal properly. Always double-check that your return lines and connectors match the specifications for your upgraded system. This ensures a snug, leak-free fit that lasts under pressure.

One more pitfall is rushing the installation of the fuel pressure regulator itself. Many enthusiasts forget to clean mating surfaces thoroughly before assembly. Dirt, old gasket material, or even tiny metal shavings can prevent a perfect seal. Think of it like putting on a ring with grime underneath — it just won’t sit right. Taking a few extra minutes to prep the surfaces can save hours of troubleshooting later.

It’s also crucial to pay attention to the routing of fuel lines. Sharp bends or kinks can restrict flow and increase wear, which eventually leads to cracks and leaks. Picture a garden hose bent sharply — the water pressure builds up at that point, and the hose weakens over time. Supporting the lines properly and using smooth curves helps maintain consistent fuel pressure and protects the system’s integrity.

Lastly, don’t underestimate the value of testing your system before firing up the engine. A simple pressure test can reveal leaks early, letting you fix them without the risk of fire or engine damage. It’s like a dress rehearsal — better to catch mistakes in practice than on opening night. Investing in quality gauges and sensors to monitor fuel pressure adds another layer of safety and peace of mind.

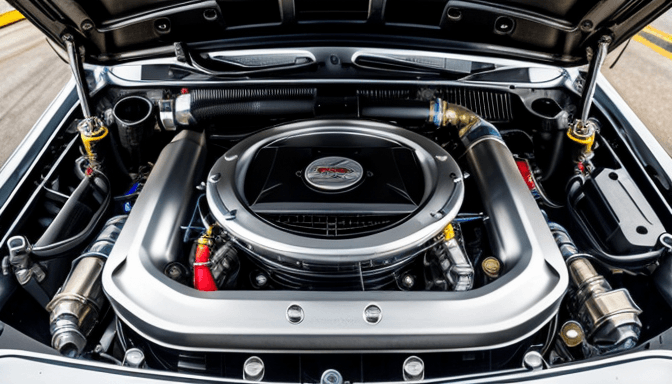

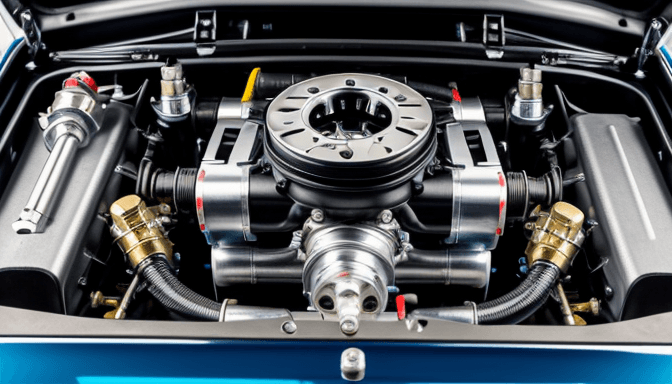

Matching the Regulator to Your Injectors and Fuel Pump

When it comes to upgrading your 2JZ engine’s fuel system, the fuel pressure regulator (FPR) isn’t just another part—it’s the heart that keeps everything in sync. Think of it as the traffic cop controlling the flow of fuel to your injectors, ensuring they get just the right amount at the right time. But here’s the catch: if your regulator isn’t matched to your injectors and fuel pump, you’re setting yourself up for headaches down the road.

Let’s break it down. Your fuel injectors demand a certain pressure to spray fuel properly. Too little pressure? They’ll struggle to deliver enough fuel, causing lean conditions that can fry your engine. Too much pressure? You risk flooding the cylinders and wasting fuel. The fuel pump, on the other hand, sets the volume and pressure ceiling. If the pump can’t keep up with the regulator’s demands, you’ll starve your engine during high load situations.

So, how do you find the sweet spot? Start by knowing your injector size and flow rate. For example, if you’re running 1000cc injectors, your regulator needs to maintain a pressure that allows those injectors to operate efficiently without forcing the pump to work overtime. A high-flow pump paired with a low-pressure regulator? That’s like having a firehose with a kink in the nozzle—frustrating and inefficient.

Here’s a simple way to visualize it: imagine your fuel pump as a water pump and the fuel pressure regulator as a valve. The pump pushes fuel through the valve to the injectors. If the valve is too tight (high pressure), the pump struggles. If it’s too loose (low pressure), the injectors don’t get enough fuel pressure. Both scenarios hurt performance.

In practice, many tuners recommend choosing an adjustable FPR that can be dialed in according to your injector specs and pump capacity. This flexibility is crucial when you switch fuels, like moving from gasoline to E85, which often requires higher base fuel pressure. Remember, the goal is balance—your regulator should neither starve nor flood the injectors but maintain a steady, reliable pressure that matches your entire fuel delivery setup.

If you’re unsure about the numbers, consulting manufacturer specs or reaching out to experienced tuners can save you from costly trial and error. After all, a well-matched fuel pressure regulator, injectors, and pump combo is like a well-rehearsed band—each part plays its role perfectly, creating harmony under the hood.

Using a Gauge and Sensor to Monitor Fuel Pressure

Imagine driving your 2JZ-powered beast without knowing if the fuel pressure is steady or dropping like a rollercoaster. Sounds risky, right? That’s where a fuel pressure gauge and sensor step in, acting like your engine’s heartbeat monitor. They give you real-time feedback, so you’re never flying blind. A gauge lets you see the pressure at a glance, while a sensor feeds data to your ECU or a digital display, warning you if things start going south.

Why is this so crucial? Well, inconsistent fuel pressure can cause your engine to run lean or rich, which is like throwing a wrench into the finely tuned machine. This can lead to poor performance, hesitation, or worse—engine damage. When you’re pushing your 2JZ to the limits, especially with boosted setups or E85 fuel, every drop or spike in pressure matters. Monitoring helps you catch leaks, clogged filters, or failing pumps before they become costly headaches.

Setting up a gauge isn’t rocket science, but placement matters. You want it close enough to the regulator or fuel rail to get accurate readings without risking damage from heat or vibration. Many enthusiasts prefer mechanical gauges for their simplicity and reliability, but electronic sensors paired with a digital display offer the convenience of monitoring on the fly, even while driving.

Here’s a quick tip from personal experience: I once ignored a slow pressure drop during a track day. By the time I noticed, the engine was already running rough, costing me a day of fun and a pricey tune-up. A simple gauge or sensor could’ve saved me that hassle by alerting me early.

In short, adding a gauge and sensor to your fuel system is like giving your 2JZ a pair of eyes and ears. It’s not just about numbers; it’s about peace of mind. When you can see what’s happening under the hood, you can react fast, tweak your tune, and keep your engine humming smoothly. Don’t let fuel pressure be a mystery—keep it front and center.

Frequently Asked Questions

- Why is upgrading the fuel pressure regulator important for a 2JZ engine?Upgrading the fuel pressure regulator (FPR) is crucial because it ensures consistent fuel delivery, especially when pushing your 2JZ engine to higher power levels. Think of the FPR as the gatekeeper controlling how much fuel flows to your engine. Without the right pressure, your engine can run lean or rich, leading to poor performance or even damage. A high-quality, adjustable FPR helps you fine-tune fuel pressure to match your build’s demands, keeping everything running smoothly.

- What’s the difference between return and returnless fuel systems?Return systems have a fuel line that sends excess fuel back to the tank, helping maintain steady pressure. Returnless systems, on the other hand, regulate fuel pressure at the tank without sending fuel back. For a 2JZ, return systems often provide better control and reliability under high boost, but returnless setups are simpler and cleaner. It’s like choosing between a two-way street (return) and a one-way street (returnless) for your fuel flow—each has its perks depending on your setup.

- Which brands are best for 2JZ fuel pressure regulators?Top brands like Aeromotive, Radium, and Fuelab are favorites among 2JZ enthusiasts. They offer reliable, high-performance FPRs that can handle increased fuel demands and harsh conditions. These brands also provide adjustable options, so you can dial in the perfect pressure for your engine, whether you’re running E85 or high boost. Choosing a trusted brand is like picking a seasoned guide for your fuel system journey—safer and more effective.

- How do I adapt an aftermarket regulator to the stock fuel rail?Adapting an aftermarket FPR usually involves some minor modifications like using specific adapters or fittings to match the stock fuel rail ports. The key is ensuring a leak-free, secure connection without major fabrication. Many 2JZ builders use plug-and-play kits or custom brackets to make this swap easier. Think of it like swapping out a car’s tires—you want the right fit to keep everything running smoothly without surprises.

- What base fuel pressure should I set for boosted or E85 applications?Base fuel pressure settings vary, but a common rule of thumb is to increase pressure proportionally with boost. For E85, which requires more fuel, you’ll want a higher base pressure to keep the engine happy and avoid lean conditions. Adjusting fuel pressure is like tuning the volume on your stereo—you want it loud enough to hear clearly but not so loud it distorts the sound.

- What return line sizes and materials work best for a 2JZ?Choosing the right return line size and material is vital to prevent pressure drops and ensure durability. Typically, using stainless steel braided lines or high-quality PTFE hoses with at least -6AN or -8AN diameter works well. These materials resist heat and wear, much like wearing sturdy boots on a tough hike—they protect your system and keep fuel flowing smoothly.

- How can I avoid common installation mistakes and fuel leaks?Fuel leaks are a nightmare and can be dangerous. To avoid them, always double-check fittings for proper sealing, use thread sealant designed for fuel systems, and never overtighten components. Also, inspect hoses for cracks or wear before installation. Think of it like sealing a jar—you want a tight, secure lid to keep everything inside safe and sound.

- How do I match my fuel pressure regulator to my injectors and fuel pump?Your FPR should complement your injector size and pump capacity to maintain balanced fuel delivery. Oversized injectors need a regulator that can handle higher flow rates without pressure fluctuations. It’s like pairing the right shoes with your running style—you want everything to work in harmony for peak performance.

- Why should I use a gauge and sensor to monitor fuel pressure?Installing a fuel pressure gauge and sensor lets you keep a constant eye on your system, catching issues before they become costly problems. Monitoring pressure helps you fine-tune your setup and ensures safety under demanding conditions. Think of it as a dashboard warning light—it keeps you informed and in control.