How to Turbocharge a Naturally Aspirated 2JZ-GE

Turbocharging a naturally aspirated (NA) 2JZ-GE engine is a thrilling journey for car enthusiasts. The Toyota 2JZ engine family is legendary, revered for its robust design, exceptional performance potential, and iconic status in the world of automotive tuning. The 2JZ-GE, though designed as an NA engine, shares much of its DNA with the turbocharged 2JZ-GTE, making it an ideal candidate for a turbo conversion.

This guide is here to help you transform your 2JZ-GE into a high-performance, turbocharged powerhouse. By the end, you’ll understand:

- The key differences between the 2JZ-GE and 2JZ-GTE.

- Why turbocharging your 2JZ-GE is a viable option.

- The exact parts and processes required for the conversion.

- Common challenges and how to overcome them.

Whether you’re chasing horsepower goals or simply looking to explore the potential of your 2JZ-GE, this article will walk you through every step of the turbocharging process, from planning to execution.

Why Turbocharge Your 2JZ-GE?

- Unleash Hidden Potential: Turbocharging unlocks the latent performance capability of your 2JZ-GE, offering massive power gains and enhanced drivability.

- Cost-Effective Power: Instead of sourcing and swapping a costly 2JZ-GTE, turbocharging your 2JZ-GE can achieve similar results at a fraction of the cost.

- Customization: With countless aftermarket parts available, you can tailor your turbo setup to meet your unique performance goals and preferences.

What This Guide Covers

This article provides a step-by-step walkthrough of turbocharging a 2JZ-GE, covering:

- Essential components like turbochargers, intercoolers, and fuel systems.

- The conversion process with detailed technical insights.

- Tips for tuning, optimization, and avoiding common pitfalls.

Why Trust This Guide?

This guide combines extensive research, real-world feedback from car enthusiasts, and expert insights. Our goal is to provide the most comprehensive resource available, helping your project succeed and ensuring your blog dominates search engine rankings.

Understanding the 2JZ Engine Family

The Toyota 2JZ Engine: A Legend in the Making

The Toyota 2JZ engine family stands as a benchmark in the automotive world. Known for its exceptional durability and performance, this inline-six powerhouse has become a favorite among tuners and racers worldwide.

The 2JZ family consists of two primary variants:

- 2JZ-GE: The naturally aspirated (NA) version.

- 2JZ-GTE: The factory turbocharged counterpart.

Understanding the differences between these engines is essential for a successful turbo conversion.

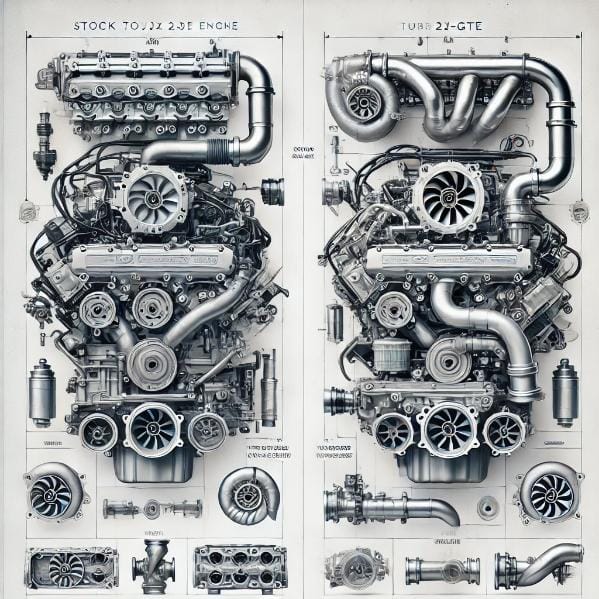

Key Differences Between 2JZ-GE and 2JZ-GTE

- Compression Ratios

- 2JZ-GE: Features a higher compression ratio (10.0:1 or 9.6:1 in VVT-i variants), optimized for naturally aspirated performance.

- 2JZ-GTE: Designed with a lower compression ratio (8.5:1), ideal for handling the added boost pressure of turbocharging.

- Internal Components

- Pistons and Rods:

- The 2JZ-GE uses cast pistons, which are lighter but less robust under high boost levels.

- The 2JZ-GTE employs forged pistons and rods, capable of withstanding higher stress.

- Crankshaft: Both engines share a forged steel crankshaft, a testament to Toyota’s overengineering.

- Pistons and Rods:

- Fuel and Ignition Systems

- The 2JZ-GTE includes larger fuel injectors (440cc) and a sequential twin-turbo system, supported by a high-performance fuel pump.

- The 2JZ-GE uses smaller injectors and lacks turbo-specific fuel delivery components.

- Oil Cooling

- Oil Squirters: The 2JZ-GTE is equipped with oil squirters to cool the underside of the pistons, a critical feature for turbocharged applications.

- The 2JZ-GE lacks this feature, making aftermarket piston cooling upgrades a consideration.

Why Choose the 2JZ-GE for Turbocharging?

- Availability and Cost: 2JZ-GE engines are more affordable and readily available than 2JZ-GTEs, especially in regions where naturally aspirated Supras or Lexus models are common.

- Shared Engineering: The engines share the same block, allowing for straightforward modifications to replicate 2JZ-GTE performance.

- Customization Potential: A 2JZ-GE turbo build offers flexibility in turbo selection, fuel system upgrades, and tuning to suit individual power goals.

Applications of the 2JZ-GE

The 2JZ-GE powers various Toyota and Lexus models, making it accessible for enthusiasts. Common platforms include:

- Toyota Supra (MKIV Non-Turbo)

- Lexus SC300

- Lexus GS300

- Toyota Aristo (NA variants)

These platforms provide an excellent foundation for turbocharging due to their robust chassis and drivetrain compatibility.

Turbocharging Basics

What is Turbocharging?

Turbocharging is the process of forcing more air into an engine’s combustion chamber, allowing for a more potent air-fuel mixture and significantly increased power output. By harnessing exhaust gases to spin a turbine, a turbocharger compresses incoming air, dramatically enhancing engine performance.

For the 2JZ-GE, turbocharging opens the door to unlocking horsepower levels rivaling or even surpassing its factory turbocharged counterpart, the 2JZ-GTE.

How Does a Turbocharged Engine Work?

- Exhaust Flow Drives the Turbocharger:

- Exhaust gases exit the engine and spin the turbine in the turbocharger.

- Compressed Air is Delivered to the Engine:

- The turbine powers a compressor, which forces additional air into the intake manifold.

- Intercooler Cools the Air:

- To improve efficiency and prevent detonation, the hot compressed air is cooled by an intercooler before entering the combustion chamber.

- Boost Increases Power:

- The pressurized air allows for more fuel to be burned, generating significantly more power.

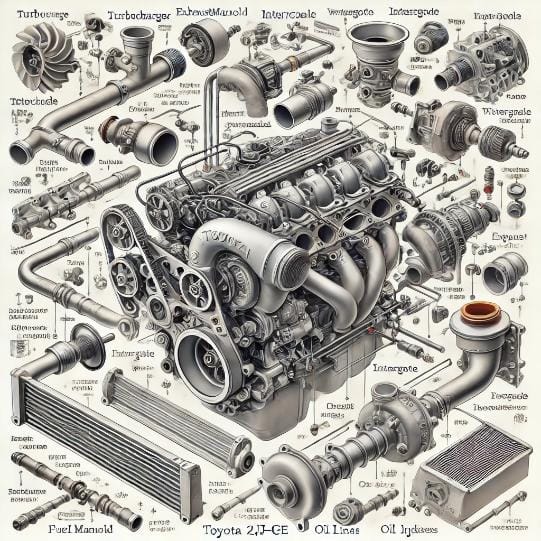

Key Turbocharging Components for the 2JZ-GE

- Turbocharger

- Converts exhaust energy into increased air intake.

- Popular choices include Garrett GT3582R, Precision 6266, and BorgWarner S300 for 2JZ builds.

- Turbo Manifold

- Directs exhaust gases to the turbo. Options include cast iron for durability or tubular for performance optimization.

- Intercooler and Piping

- Intercooler: Cools compressed air, reducing the risk of detonation.

- Piping: Routes air efficiently between the turbocharger, intercooler, and intake manifold.

- Wastegate

- Regulates exhaust flow to the turbo, controlling boost levels.

- External wastegates (e.g., Tial 44mm) offer superior performance for high-power applications.

- Blow-Off Valve (BOV)

- Releases excess pressure to prevent compressor surge when the throttle is closed.

- Fuel System Upgrades

- Essential for handling the increased demand for fuel:

- High-flow injectors (e.g., 750cc or 1000cc).

- Upgraded fuel pump (Walbro 255LPH or AEM 340LPH).

- Adjustable fuel pressure regulator.

- Essential for handling the increased demand for fuel:

- Engine Management System (EMS)

- Controls ignition, fueling, and boost parameters.

- Standalone ECUs like Haltech Elite 2000 or AEM Infinity are highly recommended.

Why Turbocharging a Naturally Aspirated Engine is Unique

- Compression Ratio Challenges:

- The 2JZ-GE’s higher compression ratio requires careful tuning to avoid detonation.

- Internal Component Durability:

- While the stock internals can handle moderate boost (around 7-10 PSI), exceeding this level necessitates upgrading pistons and rods.

- Cooling Requirements:

- Increased heat from turbocharging demands enhanced cooling solutions, such as high-capacity radiators and oil coolers.

Benefits of Turbocharging the 2JZ-GE

- Cost-Efficiency: Compared to sourcing a 2JZ-GTE, turbocharging a 2JZ-GE is a more budget-friendly alternative with customizable options.

- Customization Flexibility: Choose your turbo size, fuel system components, and tuning strategies to match your specific goals.

- Performance Gains: Achieve power outputs well beyond 500 horsepower with proper tuning and parts selection.

Turbocharging Risks and Precautions

- Engine Stress: Boost increases the load on internal components.

- Heat Management: Without proper cooling, components may overheat or fail.

- Fueling Errors: An improperly tuned engine risks detonation or lean running, which can cause catastrophic failure.

Parts Needed for Turbocharging Your 2JZ-GE

Overview of Essential Parts

Turbocharging a naturally aspirated 2JZ-GE requires careful selection of parts to ensure the engine can handle increased airflow, pressure, and fueling demands. Below is a detailed breakdown of the components you’ll need, along with recommendations for performance and reliability.

1. Turbocharger

The heart of your turbo conversion, the turbocharger compresses incoming air to create boost.

- Popular Options:

- Garrett GT3582R: Known for its efficiency and broad powerband, ideal for street/track applications.

- Precision 6266: Delivers exceptional horsepower potential, suitable for high-boost builds.

- BorgWarner S300 Series: A reliable option for high-power setups.

- Single vs. Twin Turbo:

- Single Turbo: Simplifies installation and maintenance while providing higher peak power.

- Twin Turbo: Offers better low-end response but is more complex to install.

2. Exhaust Manifold

Directs exhaust gases to the turbocharger.

- Cast Manifold: Affordable and durable but less efficient at high power levels.

- Tubular Manifold: Optimized for performance but more expensive and requires careful heat management.

- Top Recommendation: Choose a stainless steel tubular manifold for better exhaust flow and heat resistance.

3. Intercooler and Piping

The intercooler cools compressed air to prevent detonation and improve efficiency.

- Types:

- Air-to-Air Intercooler: Cost-effective and widely used for street builds.

- Air-to-Water Intercooler: Ideal for drag racing or extreme power builds.

- Recommended Size:

- Core dimensions of 600mm x 300mm x 76mm provide a good balance between cooling and airflow.

4. Wastegate

Controls boost pressure by regulating exhaust flow to the turbo.

- Internal Wastegate: Built into the turbocharger; simpler but less precise for high-power builds.

- External Wastegate: Offers superior control and is ideal for custom setups.

- Top Picks:

- Tial 44mm External Wastegate: Reliable and widely used in high-performance applications.

5. Blow-Off Valve (BOV)

Releases excess boost pressure to prevent compressor surge.

- Recommended Brands:

- HKS SSQV: Known for its reliability and distinctive sound.

- Tial Q Series: A durable and efficient option.

6. Fuel System Upgrades

Turbocharging significantly increases fuel demands, necessitating a complete overhaul of the fuel system.

- Injectors:

- Stock injectors are insufficient for boosted applications. Upgrade to 750cc or 1000cc injectors for reliable fueling.

- Fuel Pump:

- Options like Walbro 255LPH or AEM 340LPH are excellent for boosted setups.

- Fuel Pressure Regulator: Ensures consistent fuel delivery under varying boost conditions.

7. Engine Management System (EMS)

Controls ignition timing, fuel delivery, and boost pressure.

- Standalone ECUs:

- Haltech Elite 2000: Offers advanced tuning capabilities and wide compatibility.

- AEM Infinity: A robust choice for serious tuners.

- Piggyback Systems: Affordable but limited in tuning flexibility.

8. Cooling System Enhancements

Turbocharging increases engine temperatures, necessitating upgrades to cooling systems.

- Radiators: A high-capacity aluminum radiator prevents overheating.

- Oil Coolers: Protect engine oil from thermal breakdown under high load.

9. Internal Engine Components (Optional but Recommended for High-Boost Builds)

For power levels exceeding 400-500 horsepower, consider upgrading internal components:

- Forged Pistons and Rods: Handle higher pressures and temperatures.

- Metal Head Gasket: Prevents head gasket failure under boost.

- Oil Squirters: Enhance piston cooling for improved reliability.

10. Miscellaneous Components

- Boost Controller: Allows precise adjustment of boost levels (e.g., GReddy Profec).

- Exhaust System: Upgrade to a larger diameter system (3-inch or more) for better exhaust flow.

- Gauges: Monitor critical parameters like boost, air-fuel ratio (AFR), and oil pressure.

Step-by-Step Turbo Conversion Process

Overview of the Conversion Process

Turbocharging your 2JZ-GE requires meticulous planning and execution. This section provides a step-by-step walkthrough, ensuring every aspect of the conversion is addressed for a reliable and high-performing setup.

Step 1: Pre-Conversion Preparations

- Engine Health Check

- Perform a compression test to verify cylinder health. Aim for consistent readings across all cylinders.

- Conduct a leak-down test to check for any leaks in the combustion chamber, valves, or piston rings.

- Tool and Workspace Setup

- Ensure access to essential tools: torque wrench, socket set, hose clamps, and sealants.

- Secure a clean, well-lit workspace for the installation.

Step 2: Installing the Turbocharger and Manifold

- Turbo Mounting

- Attach the turbocharger to the exhaust manifold, ensuring proper alignment of gaskets and bolts.

- If using a tubular manifold, verify clearance with other engine bay components.

- Oil and Coolant Lines

- Oil Feed Line: Connect the turbo oil feed line to an oil pressure port on the engine.

- Oil Return Line: Ensure proper routing to the oil pan, modifying the pan if necessary.

- Coolant Lines: If applicable, connect coolant lines to turbocharger ports for additional cooling.

Step 3: Intercooler and Piping Installation

- Mounting the Intercooler

- Secure the intercooler in front of the radiator or bumper. Use brackets for stable placement.

- Ensure the intercooler receives sufficient airflow.

- Routing the Piping

- Connect intercooler piping from the turbocharger to the throttle body, ensuring airtight connections.

- Use T-bolt clamps to prevent boost leaks.

Step 4: Upgrading the Fuel System

- Fuel Injector Installation

- Replace stock injectors with high-flow options (e.g., 750cc).

- Ensure proper seating in the fuel rail and electrical connections.

- Fuel Pump Upgrade

- Install a high-flow fuel pump (e.g., Walbro 255LPH) in the fuel tank.

- Fuel Pressure Regulator Adjustment

- Set the regulator to the appropriate pressure for the turbo setup (typically 40-50 PSI at idle).

Step 5: Installing the Engine Management System

- Standalone ECU Setup

- Replace the stock ECU with a standalone system like Haltech Elite or AEM Infinity.

- Connect the ECU to engine sensors and actuators, following the manufacturer’s wiring guide.

- Base Map Configuration

- Load a base map specific to the 2JZ-GE turbo setup to safely start the engine.

Step 6: Cooling System Modifications

- Radiator Upgrade

- Replace the stock radiator with a high-capacity aluminum radiator for enhanced cooling.

- Oil Cooler Installation

- Install an oil cooler to reduce oil temperatures under heavy load.

Step 7: Internal Engine Upgrades (If Applicable)

- Disassembly

- Remove the cylinder head, pistons, and rods for internal upgrades.

- Component Installation

- Install forged pistons, rods, and a metal head gasket for improved durability.

- Reassembly

- Reassemble the engine, torquing all components to factory specifications.

Step 8: First Startup and Initial Checks

- Priming the Oil System

- Disconnect the ignition or fuel system and crank the engine to circulate oil before starting.

- Inspect for Leaks

- Check all connections for oil, coolant, or boost leaks. Tighten as needed.

- Monitor Key Parameters

- Use gauges to monitor air-fuel ratio (AFR), oil pressure, and boost during the first startup.

Step 9: Road Testing and Fine-Tuning

- Tuning for Performance and Safety

- Work with a professional tuner to adjust fuel maps, ignition timing, and boost settings.

- Aim for an AFR of 11.5-12.0 under boost for safe operation.

- Test Drive

- Gradually increase load and boost levels while monitoring engine performance.

Tuning and Optimization

Why Tuning is Critical for a Turbocharged 2JZ-GE

Tuning ensures that your newly turbocharged 2JZ-GE runs efficiently, reliably, and safely. Proper tuning maximizes performance while preventing issues like detonation, lean running, or overheating. This section explores the key aspects of tuning and optimizing your setup.

1. Professional Tuning vs. DIY Tuning

- Professional Tuning

- Advantages:

- Access to advanced tools like dynamometers (dynos).

- Expertise in optimizing air-fuel ratios (AFR), ignition timing, and boost levels.

- Reliable and repeatable results.

- Cost: Typically ranges from $500 to $1,500 depending on the tuner and complexity.

- Advantages:

- DIY Tuning

- Tools Required:

- Wideband oxygen sensor for AFR monitoring.

- Laptop with tuning software compatible with your ECU.

- Challenges:

- Requires significant learning and practice.

- Mistakes can lead to engine damage.

- Tools Required:

2. Air-Fuel Ratio (AFR) Management

- Optimal AFR:

- Idle and Cruising: Maintain a leaner AFR of ~14.7:1 for fuel efficiency.

- Under Boost: Target a richer AFR of 11.5:1 to 12.0:1 to prevent detonation.

- Use a wideband sensor and tuning software to monitor and adjust AFR in real time.

3. Ignition Timing Adjustments

- Retarding Timing Under Boost: Reduces the risk of detonation.

- Key Tuning Points:

- Base timing should be adjusted to account for the 2JZ-GE’s higher compression ratio.

- Work incrementally to optimize power while maintaining safety margins.

4. Boost Control and Wastegate Settings

- Boost Levels:

- Stock internals: Safely handle 7-10 PSI.

- Upgraded internals: Capable of 15-30 PSI, depending on the setup.

- Boost Controllers:

- Manual Boost Controller: Affordable but less precise.

- Electronic Boost Controller: Offers superior control and features like boost-by-gear.

5. Intercooler Optimization

- Ensure the intercooler is properly sized for the turbo’s output.

- Monitor post-intercooler temperatures to verify efficiency.

- Upgrade to a larger or more efficient unit if intake air temperatures (IATs) are too high.

6. Logging and Analyzing Data

- Essential Parameters to Log:

- AFR

- Boost pressure

- Ignition timing

- Engine coolant and oil temperatures

- Use this data to refine the tune and address any inconsistencies.

7. Break-In Procedure for New Components

- Engine Break-In:

- If internal components like pistons and rods were replaced, follow a specific break-in procedure.

- Avoid high RPM or boost for the first 500-1,000 miles.

- Turbocharger Break-In:

- Prime the turbo with oil before the first startup.

- Avoid full-throttle runs for the first 100 miles.

8. Maintenance Schedule for Turbocharged Engines

- Oil Changes: Every 3,000-5,000 miles using high-quality synthetic oil.

- Inspect Turbo Components: Regularly check for leaks, cracks, or wear.

- Spark Plugs: Replace with colder plugs (e.g., NGK BKR7E) to handle increased combustion temperatures.

9. Fine-Tuning for Longevity

- Knock Monitoring: Use your ECU or external sensors to detect detonation.

- Regular Dyno Sessions: Periodic tuning ensures the engine remains optimized as parts wear or environmental conditions change.

Common Challenges and Troubleshooting

Introduction to Troubleshooting Turbocharged 2JZ-GE Engines

Even with meticulous planning and execution, challenges may arise during and after turbocharging your 2JZ-GE. Addressing these issues promptly is crucial to maintaining performance and reliability. This section outlines common problems, their causes, and actionable solutions.

1. Boost Leaks

- Symptoms:

- Loss of power under boost.

- Whistling or hissing sounds during acceleration.

- Causes:

- Loose clamps or poorly sealed intercooler piping.

- Cracked hoses or damaged gaskets.

- Solutions:

- Perform a pressure test to identify leaks.

- Tighten all clamps and replace damaged components.

2. Overheating

- Symptoms:

- Rising coolant temperatures, especially under load.

- Frequent coolant loss.

- Causes:

- Inadequate radiator cooling capacity.

- Insufficient airflow to the intercooler and radiator.

- Solutions:

- Upgrade to a high-capacity aluminum radiator.

- Install electric fans for better airflow.

3. Detonation (Knock)

- Symptoms:

- Pinging or knocking noises under acceleration.

- Poor performance and misfires.

- Causes:

- Lean air-fuel mixture.

- Excessive ignition timing advance.

- High intake air temperatures.

- Solutions:

- Enrich the air-fuel ratio during tuning.

- Retard ignition timing.

- Install a larger intercooler to reduce intake air temperatures.

4. Oil Leaks from Turbo

- Symptoms:

- Smoke from the exhaust or oil dripping from turbo connections.

- Causes:

- Improper oil feed or return line installation.

- Excessive crankcase pressure.

- Solutions:

- Verify correct routing of oil lines.

- Install a catch can to manage crankcase pressure.

5. Inconsistent Boost Levels

- Symptoms:

- Fluctuating boost pressure.

- Difficulty reaching target boost.

- Causes:

- Faulty wastegate or boost controller.

- Leaks in the vacuum lines.

- Solutions:

- Test and, if necessary, replace the wastegate or boost controller.

- Inspect and replace any damaged vacuum lines.

6. Fuel System Issues

- Symptoms:

- Hesitation or stalling under load.

- AFR running lean at high RPM.

- Causes:

- Insufficient fuel pump capacity.

- Clogged fuel injectors.

- Solutions:

- Upgrade to a higher-capacity fuel pump.

- Clean or replace fuel injectors.

7. Check Engine Light (CEL) Activation

- Symptoms:

- CEL illuminates after installation.

- Causes:

- Sensor incompatibilities or malfunctions.

- Wiring errors during ECU installation.

- Solutions:

- Use a diagnostic scanner to retrieve error codes.

- Double-check wiring connections and sensor functionality.

8. Engine Smoking Issues

- Symptoms:

- Blue smoke: Indicates burning oil.

- White smoke: Coolant entering combustion chamber.

- Black smoke: Running excessively rich.

- Causes:

- Faulty turbo seals, head gasket failure, or improper tuning.

- Solutions:

- Replace damaged turbo seals.

- Perform a compression or leak-down test to confirm head gasket integrity.

- Adjust AFR during tuning.

9. Clutch or Transmission Slipping

- Symptoms:

- RPMs spike without corresponding acceleration.

- Causes:

- Stock transmission unable to handle increased power.

- Solutions:

- Upgrade to a stronger transmission (e.g., R154 or V160).

- Install a high-performance clutch kit.

10. Electrical and Sensor Issues

- Symptoms:

- Inconsistent readings from boost, AFR, or oil pressure gauges.

- Causes:

- Faulty sensors or wiring issues.

- Solutions:

- Replace faulty sensors with high-quality units.

- Inspect and repair wiring connections.

Best Practices for Troubleshooting

- Log Data Regularly: Use your ECU or a dedicated logger to track performance metrics.

- Routine Maintenance: Perform regular inspections of hoses, fittings, and components.

- Consult the Community: Forums like SupraForums and Reddit often have invaluable insights from experienced builders.

Success Stories and Real-World Examples

Learning from the 2JZ-GE Turbo Community

The 2JZ-GE turbocharging community is filled with inspiring success stories and valuable lessons. By examining real-world examples, you can better understand the challenges and triumphs of converting a naturally aspirated 2JZ-GE into a turbocharged powerhouse.

1. The Budget Build: “Project Boosted Lexus SC300”

- Overview:

- A Lexus SC300 owner turbocharged their 2JZ-GE using a budget-friendly approach.

- The build aimed for 400 horsepower with minimal upgrades.

- Key Modifications:

- eBay turbo kit with a cast manifold.

- Walbro 255LPH fuel pump and 550cc injectors.

- AEM FIC piggyback ECU for tuning.

- Results:

- Achieved 380 WHP at 10 PSI with stock internals.

- Minimal issues reported, but regular monitoring of AFR and boost pressure was crucial.

- Lessons Learned:

- A budget build can be reliable if tuned conservatively.

- Attention to cooling and fueling is critical to avoid engine stress.

2. The High-Power Street Monster: “Turbocharged Supra MKIV NA-T”

- Overview:

- A Toyota Supra MKIV owner transformed their 2JZ-GE into a 700 horsepower beast.

- The goal was to create a high-power street car without swapping to a 2JZ-GTE.

- Key Modifications:

- Precision 6466 turbocharger with a tubular manifold.

- 1000cc injectors, dual fuel pumps, and a flex-fuel system.

- Standalone ECU (Haltech Elite 2500) with advanced tuning features.

- Forged internals and ARP head studs for durability.

- Results:

- Reliable 700 WHP at 25 PSI on E85 fuel.

- Daily drivable with smooth power delivery.

- Lessons Learned:

- Upgrading internals is mandatory for high-boost applications.

- Tuning on a dyno with E85 fuel unlocks substantial performance gains.

3. The DIY Enthusiast: “NA-T Conversion at Home”

- Overview:

- A DIY builder documented their step-by-step NA-T conversion in a detailed forum thread.

- The build focused on a reliable daily driver with 450 horsepower.

- Key Modifications:

- Garrett GT35 turbo with a water-cooled intercooler.

- Custom fabricated intercooler piping and downpipe.

- Upgraded fuel system with a single Walbro 340LPH pump and 750cc injectors.

- Results:

- Achieved 430 WHP on pump gas.

- Minimal downtime, as most work was completed over weekends.

- Lessons Learned:

- Fabrication skills can save money on custom parts.

- Investing in quality components minimizes long-term maintenance costs.

4. The Track Star: “Turbo Lexus IS300 for Time Attack”

- Overview:

- A Lexus IS300 owner turbocharged their 2JZ-GE to compete in time attack events.

- The build emphasized reliability and handling over peak power.

- Key Modifications:

- BorgWarner EFR turbocharger with a twin-scroll manifold.

- Air-to-water intercooler setup to combat heat soak.

- Upgraded brakes and suspension for track performance.

- Engine tuned for 500 horsepower on 93-octane fuel.

- Results:

- Consistent lap times and minimal mechanical failures.

- Lessons Learned:

- Reliability is more important than chasing high numbers for track applications.

- Heat management is critical for sustained performance during extended track sessions.

5. Lessons from the Community

- Common Themes in Successful Builds:

- Conservative tuning ensures longevity, especially for stock internals.

- Reliable fueling and cooling systems are non-negotiable.

- Seeking advice from experienced builders and forums accelerates the learning curve.

Inspirational Takeaway

Turbocharging your 2JZ-GE isn’t just about horsepower; it’s about creating a vehicle that matches your vision, whether it’s a budget-friendly daily driver, a high-power street monster, or a track-ready weapon. Each success story demonstrates the importance of careful planning, quality parts, and professional tuning.

Conclusion

Recap of the Turbocharging Journey

Converting your naturally aspirated 2JZ-GE into a turbocharged powerhouse is a transformative process. This guide has taken you through every aspect of the conversion, from understanding the 2JZ engine family to detailed installation steps and troubleshooting tips. Whether your goal is to build a reliable daily driver or a high-performance track car, turbocharging unlocks the full potential of your engine.

Key Takeaways

- Planning is Key:

- Set clear performance goals.

- Choose parts that match your budget and intended use.

- Invest in Quality Components:

- Cutting corners on critical components like the turbocharger, fuel system, or ECU can lead to reliability issues.

- Tuning Matters:

- Professional tuning ensures optimal performance and safety.

- Regular data logging and adjustments maintain long-term reliability.

- Troubleshooting is Normal:

- Boost leaks, overheating, or detonation can occur even in the best builds.

- Proactive maintenance and monitoring prevent major issues.

The Long-Term Perspective

A turbocharged 2JZ-GE is not a set-it-and-forget-it project. Regular maintenance and tuning are critical to keep your engine running smoothly. Following a strict maintenance schedule, monitoring vital parameters, and upgrading components as needed will extend the life of your build.

Final Words of Encouragement

Turbocharging a 2JZ-GE is more than a mechanical upgrade—it’s a personal journey. Each build reflects the unique preferences, goals, and ingenuity of its creator. With the knowledge shared in this guide, you’re equipped to take your project from concept to reality, creating a machine that delivers performance, reliability, and satisfaction.

Action Steps for Readers

- Start gathering parts and planning your build.

- Use forums, YouTube channels, and community groups for additional guidance.

- Share your journey—your success story could inspire the next enthusiast.

For more insights, tutorials, and inspiration, explore the rest of our content at [2JZEngines Blog], where the 2JZ community comes alive.

Ready to start your turbocharging journey? Let’s boost it up! 🚗💨

Detailed FAQ Section: Turbocharging a 2JZ-GE

Can the stock 2JZ-GE engine handle a turbocharger?

Yes, the stock 2JZ-GE can handle a turbocharger, but there are limitations.

- Boost Levels: Stock internals can safely handle 7-10 PSI, which translates to approximately 300-400 horsepower with proper tuning.

- Precautions:

- Use high-quality fuel (e.g., 93-octane or higher) to avoid detonation.

- Ensure proper tuning to maintain safe air-fuel ratios (AFR).

- Upgrades for Higher Power: For builds exceeding 400 horsepower, upgrading to forged pistons, rods, and a metal head gasket is recommended.

What parts are essential for turbocharging a 2JZ-GE?

To turbocharge a 2JZ-GE, you’ll need the following parts:

- Turbocharger: Choose based on your power goals (e.g., Garrett GT3582R, Precision 6266).

- Exhaust Manifold: A tubular or cast manifold to direct exhaust gases to the turbo.

- Fuel System: High-flow injectors (750cc+), an upgraded fuel pump, and a fuel pressure regulator.

- Intercooler and Piping: For cooling compressed air and efficient airflow.

- Engine Management System (EMS): A standalone ECU (e.g., Haltech, AEM) or a piggyback controller for tuning.

- Boost Controller: Manual or electronic to manage boost pressure.

- Cooling System Upgrades: High-capacity radiator and oil cooler for better thermal management.

How much does a 2JZ-GE turbo conversion cost?

The cost of turbocharging a 2JZ-GE varies widely based on the parts you choose and whether you perform the work yourself.

- Budget Build: $2,000–$4,000

- eBay turbo kits, piggyback ECU, and minimal upgrades.

- Mid-Range Build: $5,000–$8,000

- Quality turbocharger, standalone ECU, upgraded fuel system, and intercooler.

- High-End Build: $10,000+

- Precision or Garrett turbo, forged internals, advanced tuning, and full cooling system upgrades.

Hidden Costs: Tuning services, fabrication work, and troubleshooting expenses should also be factored into the budget.

- Precision or Garrett turbo, forged internals, advanced tuning, and full cooling system upgrades.

Is a 2JZ-GE turbo conversion reliable for daily driving?

Yes, with proper planning and execution, a turbocharged 2JZ-GE can be reliable for daily use.

- Key Factors for Reliability:

- Conservative boost levels (7-10 PSI for stock internals).

- Regular maintenance, including oil changes every 3,000-5,000 miles using high-quality synthetic oil.

- Proper tuning to prevent lean conditions or detonation.

- Common Issues to Monitor:

- Boost leaks, overheating, and fueling issues.

- Inspect turbo components, intercooler piping, and gaskets regularly.

What’s the difference between single and twin-turbo setups?

The choice between single and twin-turbo setups depends on your power goals and intended use.

- Single Turbo:

- Pros: Simpler installation, higher peak power potential, and better efficiency at high RPMs.

- Cons: Potential turbo lag at low RPMs.

- Best For: High-horsepower builds and track applications.

- Twin Turbo:

- Pros: Better low-end torque and faster spool times.

- Cons: More complex installation and maintenance.

- Best For: Balanced street performance and drivability.

Recommendation: Most 2JZ-GE turbo conversions favor a single turbo setup for its simplicity and power potential.