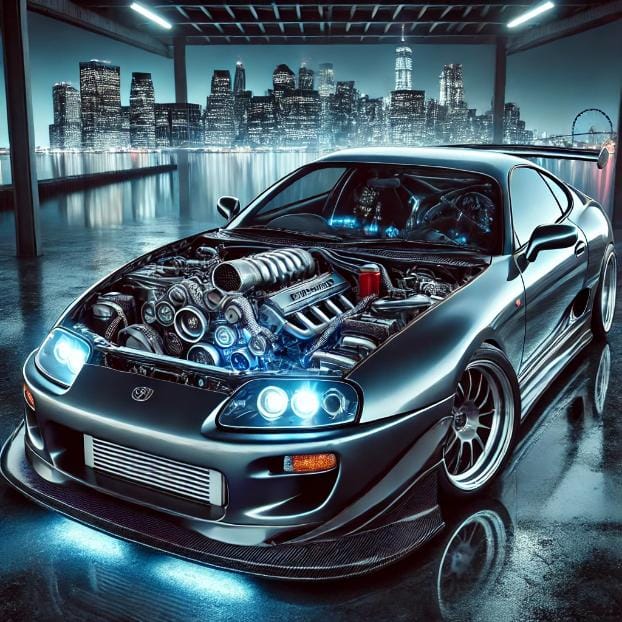

The Toyota 2JZ engine has achieved legendary status in the world of performance tuning. Originally designed for durability and reliability, its over-engineered design makes it a favorite among car enthusiasts aiming to push the boundaries of maximum horsepower. With a solid iron block, six-cylinder inline configuration, and unparalleled tuning potential, the 2JZ is capable of delivering well over 1,000 horsepower with the right modifications.

In this comprehensive guide, we will explore everything you need to know to unlock the full potential of your 2JZ engine. Whether you’re working with the naturally aspirated 2JZ-GE or the turbocharged 2JZ-GTE, this step-by-step roadmap will walk you through optimizing air/fuel ratios, adjusting ignition timing, upgrading forced induction components, and much more.

Our focus is on delivering practical advice that balances raw horsepower with reliability, ensuring your engine is ready for both the track and the street. We’ve also incorporated insights from top tuning experts, competitive SEO strategies, and cutting-edge tuning technologies to ensure this article is your ultimate 2JZ tuning resource.

By the end of this guide, you’ll have the knowledge and confidence to take your 2JZ to the next level, making it a true powerhouse while outranking competitors in both performance and search results.

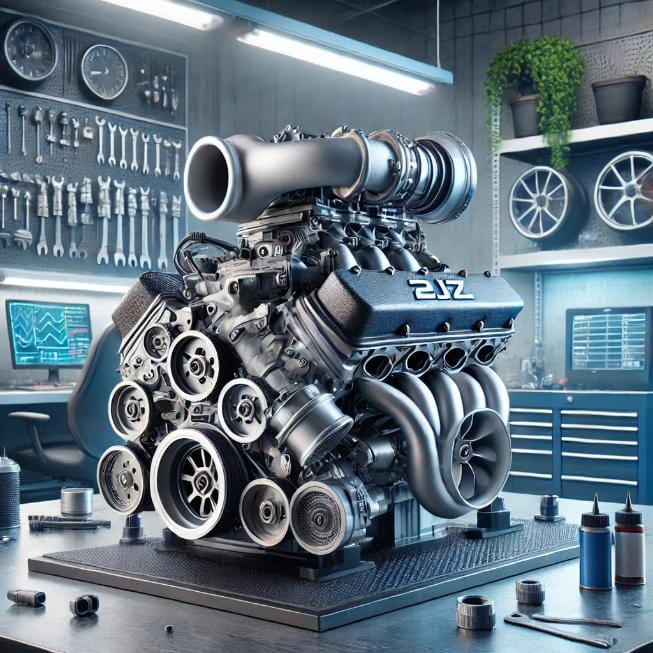

Understanding the 2JZ Engine: Foundation for High Performance

What Makes the 2JZ So Special?

The Toyota 2JZ engine stands as a pinnacle of engineering brilliance, celebrated for its robust design and unparalleled tuning potential. Whether it’s the naturally aspirated 2JZ-GE or the turbocharged 2JZ-GTE, both variants share a foundation of durability that has made them favorites among tuners worldwide.

- 2JZ-GE: The naturally aspirated variant features a 10:1 compression ratio and delivers around 220 horsepower in its stock configuration. It’s a reliable base for naturally aspirated builds or turbocharged conversions.

- 2JZ-GTE: Equipped with twin turbos and a lower compression ratio of 8.5:1, the GTE version was engineered for higher power applications, capable of producing up to 320 horsepower in stock form. With aftermarket upgrades, it can easily surpass 1,000 horsepower.

Both engines boast a cast-iron block, a six-cylinder inline layout, and a 24-valve DOHC cylinder head. This combination provides not only exceptional reliability but also ample room for modifications to achieve higher performance.

Key Features of the 2JZ Engine

- Over-Engineered Design:

- Thick cast-iron block walls support immense horsepower levels without compromising reliability.

- Durable internals make it a popular choice for high-boost applications.

- Inline-Six Configuration:

- Naturally balanced for smooth operation, reducing wear and tear over time.

- Aftermarket Support:

- The 2JZ has one of the largest aftermarket ecosystems, with parts readily available for everything from turbo upgrades to standalone ECUs.

- Turbocharged Potential:

- The 2JZ-GTE’s sequential twin-turbo system is iconic for its performance, and many enthusiasts upgrade to a single, larger turbo for even greater output.

- Tuning Flexibility:

- Whether you’re building a drag car, a circuit racer, or a street machine, the 2JZ adapts to a wide range of performance needs.

Variants Overview: VVTi vs. Non-VVTi

The later versions of the 2JZ introduced Toyota’s Variable Valve Timing with intelligence (VVTi) system, which improves efficiency and low-end torque. However, non-VVTi engines are often preferred for high-performance builds due to their simpler design and ease of tuning.

Pre-Tuning Preparations

Before diving into the tuning process, it’s crucial to ensure that your 2JZ engine is in optimal condition. Proper preparation can save you time, money, and frustration by addressing potential issues upfront and laying the foundation for a successful build.

Initial Health Check of Your Engine

To handle the increased stress that comes with high horsepower, your 2JZ engine must be mechanically sound. Conduct the following checks to assess its current state:

- Compression Test

- Measure the pressure in each cylinder to ensure consistency. Variations in compression can indicate worn piston rings, damaged valves, or head gasket issues.

- Ideal results: Each cylinder should fall within 5-10% of the others.

- Leak-Down Test

- Identify any leaks in the combustion chamber that could compromise performance. This test pinpoints issues in the piston rings, valves, or cylinder head.

- Inspect for Signs of Wear

- Check for oil leaks, damaged seals, and signs of overheating.

- Inspect timing components like the belt or chain for wear or slack.

- Fluid Check

- Replace old oil with high-performance synthetic oil designed for turbocharged engines.

- Ensure coolant levels are adequate and compatible with high temperatures.

Necessary Tools and Equipment for Tuning

Having the right tools ensures precise adjustments and reduces the risk of errors during the tuning process. Here’s a checklist of essential items:

- Wideband O2 Sensor

- Crucial for monitoring air/fuel ratios in real time to optimize combustion.

- Boost Gauge

- Provides accurate readings of boost pressure to ensure you stay within safe levels.

- Fuel Pressure Regulator and Gauge

- Allows fine-tuning of fuel delivery for consistent performance.

- Tuning Software

- Options like Haltech, AEM Infinity, or Link ECU provide comprehensive control over engine parameters.

- Dyno Access

- A dynamometer is essential for measuring horsepower and torque while fine-tuning engine performance.

- Basic Hand Tools

- Quality wrenches, sockets, and torque wrenches are must-haves for engine assembly and adjustments.

Planning for Power Goals

Before modifying your 2JZ, define your power targets. Ask yourself:

- Is the build for daily driving, track days, or drag racing?

- What’s the desired horsepower range (e.g., 400HP, 600HP, or 1,000HP)?

Setting realistic goals helps prioritize upgrades and ensures the components you choose are compatible with each other.

Air Intake and Exhaust System Upgrades

To maximize the performance of your 2JZ engine, improving airflow is critical. Upgrading the intake and exhaust systems allows your engine to “breathe” more efficiently, directly enhancing combustion and overall horsepower.

Upgrading the Air Intake System

A well-designed air intake system increases the volume of cool, dense air entering the engine, which results in more powerful combustion. Here’s what to consider:

- High-Flow Air Filters

- Replace the stock air filter with a high-performance option from brands like K&N or HKS.

- Benefits: Better airflow and filtration, protecting the engine from contaminants.

- Cold Air Intake (CAI) Systems

- A CAI relocates the intake away from the engine bay to draw cooler air.

- Cooler air is denser, allowing for improved combustion efficiency and more horsepower.

- Short Ram Intake

- For those seeking simplicity, a short ram intake provides a compact alternative.

- While less effective in heat management, it improves airflow over stock systems.

- Avoiding Bottlenecks

- Ensure intake piping has a consistent diameter and is free from sharp bends that restrict airflow.

- Silicone hoses or mandrel-bent aluminum tubing are excellent options.

Enhancing the Exhaust System

Freeing up the exhaust flow is just as important as improving intake airflow. A performance exhaust reduces backpressure, enabling the engine to expel gases efficiently.

- Cat-Back Exhaust Systems

- Replace the stock exhaust with a high-flow cat-back system for better performance and sound.

- Look for systems with mandrel bends and larger diameters (3” to 3.5” recommended for turbo setups).

- Turbo-Back Exhaust

- For turbocharged 2JZ engines, a turbo-back system maximizes exhaust gas flow from the turbocharger outlet.

- Benefits: Increased power potential, reduced turbo lag, and better boost response.

- High-Flow Catalytic Converters

- Upgrade to a high-flow catalytic converter or remove it for off-road applications (where legal).

- This reduces restriction in the exhaust system without excessively increasing emissions.

- Aftermarket Headers (For 2JZ-GE)

- Naturally aspirated builds benefit significantly from aftermarket headers.

- Equal-length headers improve exhaust scavenging, enhancing power output.

Bonus: Common Pitfalls to Avoid in Airflow Mods

- Overly Large Piping

- Bigger isn’t always better. Oversized piping can reduce exhaust gas velocity, especially at lower RPMs.

- Ignoring Heat Management

- Use heat shields or wraps for intake and exhaust components to minimize heat soak and improve efficiency.

- Poor Fitment

- Ensure all aftermarket parts are compatible with the 2JZ engine and installed securely to avoid leaks or performance losses.

Improving intake and exhaust systems lays the foundation for significant horsepower gains and supports other performance upgrades like turbocharging and fuel system modifications.

Fuel System Modifications for Maximum Horsepower

Upgrading the fuel system is essential to support the increased demands of a tuned 2JZ engine. A reliable and efficient fuel delivery system ensures optimal combustion, prevents detonation, and allows for significant power gains.

Upgrading Fuel Injectors and Fuel Pumps

The stock fuel system is designed for factory horsepower levels and becomes a bottleneck when tuning for higher performance. Here’s what to focus on:

- Fuel Injectors

- Stock injectors on the 2JZ-GTE are insufficient for power goals exceeding 450HP.

- Recommended Injector Sizes:

- 550cc injectors: Suitable for ~400-500HP.

- 1,000cc injectors: Ideal for builds targeting ~600-700HP.

- 2,000cc injectors: Necessary for extreme power builds over 1,000HP.

- Choose high-impedance injectors or ensure compatibility with your standalone ECU.

- Fuel Pumps

- Upgrade to high-flow pumps like the Walbro 450 or AEM 340 to deliver consistent fuel pressure.

- For builds targeting over 700HP, consider dual fuel pumps or an in-line pump setup.

- E85 Compatibility

- If switching to E85 fuel (ethanol blend), ensure your injectors, pump, and fuel lines are ethanol-resistant.

- E85 offers a higher octane rating, allowing for increased boost and timing, but requires 30-40% more fuel flow.

Fuel Pressure Regulation

Maintaining steady fuel pressure is critical to avoid lean conditions at high RPMs or boost levels.

- Adjustable Fuel Pressure Regulators

- Replace the stock regulator with an aftermarket adjustable unit to fine-tune pressure.

- Ideal fuel pressure for the 2JZ: ~43 PSI at idle with a vacuum reference.

- Fuel Pressure Gauge

- Install a gauge to monitor pressure in real-time during tuning.

- Digital gauges provide more precise readings for high-performance setups.

Fuel Delivery Lines and Rails

Upgraded lines and fuel rails help prevent bottlenecks in fuel delivery.

- Braided Stainless Steel Lines

- Resistant to higher pressures and temperatures. Essential for high-power applications.

- High-Flow Fuel Rails

- Aftermarket fuel rails ensure equal fuel distribution to all cylinders, improving performance consistency.

Considerations for a Safe and Reliable Fuel System

- Proper Tuning

- The upgraded fuel system must be calibrated with an ECU to match the air/fuel ratio.

- Use a wideband O2 sensor to monitor AFR during tuning (ideal ratio: 11.5:1 to 12:1 under boost).

- Testing and Maintenance

- Regularly inspect fuel lines, fittings, and pumps for wear or leaks.

- Replace fuel filters more frequently, especially when running E85.

- Heat Management

- Install heat shields around fuel lines near high-temperature components to prevent vapor lock.

Why Fuel System Upgrades Matter

A properly upgraded fuel system not only supports higher horsepower levels but also protects your engine from catastrophic damage caused by lean conditions or insufficient fueling under load. With the right combination of injectors, pumps, and regulators, your 2JZ will be ready to handle extreme tuning.

Forced Induction: Turbocharging the 2JZ

The 2JZ engine’s reputation as a high-horsepower monster is largely due to its turbocharging potential. Whether you’re upgrading the factory twin-turbo setup or adding forced induction to a naturally aspirated 2JZ-GE, turbocharging is key to unlocking massive power gains.

Selecting the Right Turbocharger for Your Goals

Choosing the correct turbocharger depends on your power targets, intended use, and desired balance between power and response.

- Twin-Turbo Setup (Factory 2JZ-GTE)

- The stock sequential twin-turbo system offers good low-end response and high-RPM power.

- Upgrades include larger factory-style turbos (e.g., hybrid CT12B turbos) or switching to a parallel twin-turbo system for better airflow.

- Single-Turbo Conversion

- Many tuners opt for a single-turbo setup for its simplicity and potential for greater power.

- Turbocharger Size Recommendations:

- Small (50-60mm): Quick spool, ideal for street builds (up to ~500HP).

- Medium (60-70mm): Balanced for both street and track (~600-800HP).

- Large (70mm+): High boost for drag racing or extreme builds (1,000HP+).

- Popular Turbo Brands for 2JZ Builds

- Garrett: Known for reliable, high-performance turbos (e.g., Garrett GTX3582R).

- Precision Turbo: Offers a range of sizes for various applications.

- BorgWarner: Durable turbos with advanced boost technology.

Intercooler and Piping Upgrades

Cooling the compressed air from the turbocharger is essential for improving engine efficiency and preventing detonation.

- Front-Mount Intercoolers (FMIC)

- Larger FMICs are ideal for reducing intake air temperatures, leading to denser air and better combustion.

- Choose an intercooler core size that matches your turbo and power goals (e.g., 24″x12″x3″).

- Intercooler Piping

- Use mandrel-bent aluminum or stainless steel piping to minimize airflow restrictions.

- Optimize routing to reduce turbo lag and improve throttle response.

- Avoiding Heat Soak

- Proper placement of the intercooler is crucial to prevent heat soak in traffic or during extended driving.

Boost Control Strategies

Managing boost levels ensures your turbo setup delivers consistent and safe performance.

- Manual Boost Controllers

- Budget-friendly option for simple setups. Allows manual adjustment of boost pressure.

- Electronic Boost Controllers (EBCs)

- More precise and user-friendly, EBCs let you control boost levels on the fly.

- Popular options include GReddy Profec and HKS EVC.

- Wastegate Upgrades

- External wastegates provide better boost control compared to internal setups, especially at higher power levels.

- Sizes range from 38mm for street builds to 60mm+ for high-boost applications.

- Blow-Off Valves (BOVs)

- Prevent compressor surge and extend turbo life by releasing excess boost pressure.

Turbo Manifold Selection

The turbo manifold plays a critical role in directing exhaust gases to the turbine.

- Cast Manifolds

- Durable and affordable, ideal for moderate builds.

- Slightly heavier than tubular options.

- Tubular Manifolds

- Lightweight with better flow characteristics, suited for high-performance builds.

- More prone to cracking under extreme heat cycles, so choose high-quality materials like stainless steel.

Tuning for Forced Induction

- Air/Fuel Ratios Under Boost

- Ideal AFR: 11.5:1 to 12:1 for turbocharged applications.

- Monitor AFR with a wideband O2 sensor during tuning to avoid detonation.

- Timing Adjustments

- Retard ignition timing under boost to prevent knocking.

- Work with a standalone ECU or piggyback system for precise control.

- Boost Mapping

- Use tuning software to create custom boost maps tailored to your power goals.

- Adjust for atmospheric conditions, fuel type, and other variables.

Achieving Balance: Lag vs. Power

Turbo lag is the delay between throttle input and boost response. To minimize lag:

- Opt for ball-bearing turbos, which spool faster than journal-bearing models.

- Use shorter intercooler piping with fewer bends.

- Match your turbo size to your intended power and RPM range.

Why Turbo Upgrades Are Essential

Turbocharging transforms the 2JZ into a performance powerhouse capable of producing upwards of 1,000 horsepower. With the right combination of turbo, intercooler, and boost management, your engine can deliver exhilarating performance while maintaining reliability.

Engine Management Systems (EMS)

Upgrading the engine management system (EMS) is one of the most critical steps in tuning your 2JZ for maximum horsepower. A robust EMS gives you complete control over essential parameters like air/fuel ratios, ignition timing, and boost settings, enabling precise tuning for optimal performance and reliability.

Standalone vs. Piggyback Systems

- Standalone EMS

- Standalone systems replace the factory ECU entirely, offering unparalleled control over engine parameters.

- Advantages:

- Fully programmable for custom builds.

- Supports high-power setups with aftermarket injectors, turbos, and fuel systems.

- Recommended Options:

- Haltech Elite 2500: Popular for 2JZ builds, offering plug-and-play support with advanced features like traction control and flex-fuel compatibility.

- AEM Infinity: Known for its flexibility and ability to handle complex tuning scenarios.

- Piggyback Systems

- Piggyback ECUs work alongside the factory ECU, modifying its signals to improve performance.

- Advantages:

- Budget-friendly and easier to install.

- Good for mild builds or beginners.

- Limitations:

- Less control compared to standalone systems.

- May struggle with extreme power setups.

Key Features to Look for in an EMS

- Fuel and Ignition Mapping

- Ability to create precise fuel and ignition maps for various load and RPM conditions.

- Boost Control Integration

- Standalone ECUs often include electronic boost control functionality, eliminating the need for external controllers.

- Flex-Fuel Compatibility

- Support for ethanol blends (E85) allows for more aggressive tuning without the risk of detonation.

- Data Logging and Monitoring

- Real-time data logging helps identify issues and fine-tune settings during dyno runs or track sessions.

- Safety Features

- Built-in fail-safes like knock detection, boost cut, and overheat protection prevent engine damage.

Setting Up Your EMS

- Base Map Installation

- Most standalone systems come with a base map designed for the 2JZ.

- This provides a starting point for further tuning.

- Custom Tuning

- Use tuning software to adjust air/fuel ratios, ignition timing, and boost settings.

- A professional dyno session is recommended to maximize performance and ensure reliability.

- Sensor Calibration

- Calibrate wideband O2 sensors, MAP sensors, and knock sensors to ensure accurate data.

- Flex-Fuel Tuning (if applicable)

- For E85 setups, tune for ethanol content to take advantage of its higher octane rating.

Real-World Example: EMS Setup for 2JZ-GTE

- Scenario: Single-turbo 2JZ-GTE build targeting 800HP.

- EMS Used: Haltech Elite 2500.

- Key Adjustments:

- Fuel injectors upgraded to 1,000cc.

- Ignition timing mapped for 18 PSI of boost.

- AFR optimized to 11.5:1 under full throttle.

Why an EMS is a Game-Changer

A high-quality EMS is the cornerstone of any serious tuning project. It allows you to maximize the potential of your upgrades while protecting your engine from damage. With features like real-time monitoring and customizable maps, you can fine-tune your 2JZ to meet your exact power goals and driving needs.

Fine-Tuning Air/Fuel Ratios (AFR)

One of the most critical aspects of achieving maximum horsepower in your 2JZ engine is dialing in the correct air/fuel ratio (AFR). The AFR determines the balance of air and fuel entering the engine for combustion. Fine-tuning it ensures optimal power output, fuel efficiency, and engine longevity.

Understanding Air/Fuel Ratios

- What is AFR?

- The air/fuel ratio measures the amount of air compared to fuel in the combustion process.

- Ideal Stoichiometric Ratio: 14.7:1 (14.7 parts air to 1 part fuel).

- Optimal AFRs for Performance Tuning

- Naturally Aspirated (2JZ-GE): Target ~12.5:1 under wide-open throttle for maximum power.

- Turbocharged (2JZ-GTE): Aim for ~11.5:1 to 12:1 under boost to prevent detonation.

- Impact of AFR on Performance

- Lean Mixture (higher AFR): More air, less fuel. Risk of knocking/detonation at high power.

- Rich Mixture (lower AFR): More fuel, less air. Reduces power but protects the engine.

Tools for Monitoring and Adjusting AFR

- Wideband O2 Sensor

- Essential for real-time AFR monitoring during tuning.

- Brands like Innovate Motorsports and AEM offer accurate and reliable options.

- ECU or EMS Integration

- Use your standalone EMS to adjust fuel maps and monitor AFR changes.

- Dyno Testing

- A controlled environment allows precise adjustments under load.

- AFR Gauges

- Install an in-dash gauge for continuous monitoring during street or track use.

How to Adjust Air/Fuel Ratios

- Modify Fuel Maps in the EMS

- Use tuning software to alter fuel delivery at specific RPM ranges and load conditions.

- For example, increase fuel delivery under boost for a richer mixture.

- Increase Fuel Supply When Necessary

- Upgrade fuel injectors, pumps, or pressure regulators if the current system can’t supply enough fuel to achieve the desired AFR.

- Compensate for Environmental Factors

- High altitudes or hot climates may require adjustments to avoid running lean.

Common AFR Tuning Challenges

- Boosted Engines Running Lean

- Insufficient fuel delivery under boost can lead to catastrophic detonation.

- Solution: Ensure injectors and pumps are sized appropriately for your power goals.

- Rich Conditions Causing Fouling

- Excessive fuel can foul spark plugs and reduce power.

- Solution: Fine-tune the EMS to balance the mixture.

- Inconsistent AFR Readings

- Caused by exhaust leaks or a failing O2 sensor.

- Solution: Address any mechanical issues and replace faulty sensors.

Best Practices for AFR Tuning

- Start Conservatively

- Begin with a slightly rich AFR during initial tuning to avoid engine damage.

- Gradually lean out the mixture as you fine-tune the setup.

- Monitor Engine Temps

- Excessively lean mixtures can lead to high combustion temperatures, damaging pistons and valves.

- Utilize Closed-Loop Tuning

- Many EMS systems offer closed-loop tuning, where the ECU adjusts AFR automatically based on O2 sensor feedback.

Why AFR Tuning is Essential

Precise AFR tuning ensures that your 2JZ engine produces maximum power without sacrificing reliability. It also protects against common tuning pitfalls like detonation, overheating, or inefficient combustion. Combined with a proper EMS and fuel system, optimized AFR will allow your engine to perform at its absolute peak.

Ignition Timing Adjustments

Ignition timing plays a crucial role in extracting maximum horsepower from your 2JZ engine. Proper timing adjustments ensure that the spark plug fires at the optimal moment, allowing for efficient combustion and enhanced performance. Fine-tuning ignition timing can lead to significant gains in power and throttle response while reducing the risk of detonation.

What is Ignition Timing?

- Definition

- Ignition timing refers to when the spark plug ignites the air/fuel mixture in relation to the position of the piston in the cylinder.

- Measured in degrees before the piston reaches Top Dead Center (TDC) during the compression stroke.

- Advanced vs. Retarded Timing

- Advanced Timing: The spark occurs earlier in the compression stroke, allowing for a more complete burn.

- Benefits: Increased power and efficiency at higher RPMs.

- Risks: Can lead to detonation if overly advanced.

- Retarded Timing: The spark occurs later in the stroke, reducing peak cylinder pressure.

- Benefits: Safer for high-boost applications.

- Risks: Reduced power output and efficiency.

- Advanced Timing: The spark occurs earlier in the compression stroke, allowing for a more complete burn.

Tools Needed for Timing Adjustments

- Timing Light

- A must-have for accurately checking and adjusting ignition timing.

- Ensure the timing light is compatible with multi-cylinder engines like the 2JZ.

- EMS Tuning Software

- Standalone ECUs allow precise control of ignition timing across the entire RPM and load range.

- Knock Sensor and Monitoring Equipment

- Detects knock or detonation during tuning, enabling safer timing adjustments.

- Dyno Access

- A dynamometer helps fine-tune timing under load to maximize power.

How to Adjust Ignition Timing

- Baseline Timing Check

- Begin by verifying the factory timing settings using a timing light.

- Factory timing for the 2JZ-GTE is typically set around 10° BTDC at idle.

- Adjust Timing for Performance

- Use your EMS to advance or retard timing at specific RPM ranges.

- Turbocharged Builds:

- Advance timing slightly in low-boost situations.

- Retard timing under high boost to prevent detonation.

- Naturally Aspirated Builds:

- Advance timing across the mid-to-high RPM range for improved throttle response and power.

- Monitor Knock and AFR

- Use a wideband O2 sensor and knock detection tools to ensure safe adjustments.

- Detonation, if detected, requires retarding the timing.

- Optimize Timing Curve

- A properly tuned timing curve matches ignition timing to engine load and RPM for optimal performance across the powerband.

Best Practices for Timing Adjustments

- Incremental Adjustments

- Adjust timing in small increments (1° to 2° at a time) and test the results.

- Prioritize Safety Over Aggressiveness

- Slightly conservative timing reduces the risk of engine damage in high-power setups.

- Compensate for Boost Levels

- Retard ignition timing as boost increases to reduce cylinder pressure and prevent knocking.

- Account for Fuel Quality

- Higher-octane fuels allow for more advanced timing without detonation. If running E85, timing can be advanced more aggressively.

Timing Maps for Different Setups

- Street Builds

- Moderate advance for good response and driveability.

- Example: 15°-20° advance in mid-range RPMs under light load.

- Track Builds

- Aggressive timing curves for maximum power.

- Example: 10°-12° advance at high boost (~20 PSI).

- E85 Tuning

- Increased timing advance due to the knock-resistant nature of ethanol.

- Example: Up to 18° advance under full load with proper AFR.

Common Mistakes to Avoid

- Excessively Advanced Timing

- Can cause knocking, overheating, and piston damage.

- Always monitor with a knock sensor during tuning.

- Neglecting Boost and Fuel Adjustments

- Ignition timing should always be tuned in conjunction with boost pressure and AFR adjustments.

- Using Low-Quality Fuel

- Poor fuel quality increases the likelihood of detonation during aggressive timing adjustments.

Why Ignition Timing Matters

Properly tuned ignition timing unlocks the full potential of your 2JZ engine. It balances power, efficiency, and reliability by ensuring the combustion process occurs at the right moment. When combined with an optimized fuel system and boost settings, timing adjustments can yield substantial horsepower gains while protecting your engine from damage.

Boost Control Strategies

Boost control is a vital aspect of tuning a turbocharged 2JZ engine. By managing the amount of boost pressure produced by the turbocharger, you can optimize power delivery, improve drivability, and safeguard the engine from over-boosting or detonation.

What is Boost Control?

Boost control regulates the pressure generated by the turbocharger. This pressure determines how much air enters the engine, directly affecting power output. Efficient boost control ensures:

- Consistent performance across various conditions.

- Prevention of engine damage caused by excessive boost levels.

- Optimal turbocharger efficiency and longevity.

Manual vs. Electronic Boost Controllers

- Manual Boost Controllers (MBCs)

- Simple and cost-effective option.

- Adjusted manually via a knob or valve.

- Pros:

- Affordable and easy to install.

- No electronic components to fail.

- Cons:

- Requires manual adjustment.

- Limited precision compared to electronic controllers.

- Electronic Boost Controllers (EBCs)

- Advanced, programmable devices that automatically adjust boost pressure.

- Examples: GReddy Profec, HKS EVC.

- Pros:

- Real-time control and multiple boost presets.

- Integration with engine management systems for precise tuning.

- Cons:

- More expensive than MBCs.

- Requires proper wiring and setup.

External Wastegates vs. Internal Wastegates

- Internal Wastegates

- Built into the turbocharger housing.

- Suitable for lower-boost applications or stock setups.

- Limited flow capacity for high-boost builds.

- External Wastegates

- Mounted separately from the turbo.

- Ideal for high-boost and large turbo setups.

- Provides more precise control over boost pressure.

Popular Sizes for 2JZ Builds:

- 38mm for moderate power (~500-600HP).

- 50mm+ for extreme builds (~1,000HP+).

Blow-Off Valves (BOVs)

A blow-off valve prevents compressor surge by releasing excess pressure when the throttle closes.

- Benefits

- Extends turbocharger lifespan.

- Improves throttle response during gear shifts.

- Types

- Recirculating BOV: Routes air back into the intake system for quieter operation.

- Atmospheric BOV: Vents air to the atmosphere, producing the signature “whoosh” sound.

Boost Control Strategies

- Setting Safe Boost Levels

- For stock internals: Limit boost to ~15 PSI (400-500HP).

- For upgraded internals: Safely increase boost to ~25-30 PSI (800-1,000HP).

- Boost by Gear

- Use your EMS to reduce boost pressure in lower gears, improving traction and reducing wheel spin.

- Boost by RPM

- Gradually increase boost as RPMs rise to match airflow demands.

- Progressive Boost Control

- Ideal for drag racing or track use, where boost levels can be ramped up smoothly for optimal performance.

Monitoring Boost Pressure

- Boost Gauges

- A mechanical or digital gauge provides real-time readings of turbocharger pressure.

- Essential for spotting over-boost situations during tuning.

- EMS Data Logging

- Most standalone ECUs allow you to log and review boost levels across different RPM and load conditions.

- Fail-Safe Systems

- Some EBCs include fail-safe features to cut boost pressure if it exceeds a set threshold.

Common Boost Control Issues and Solutions

- Boost Creep

- Caused by insufficient wastegate flow.

- Solution: Upgrade to a larger wastegate or improve exhaust flow.

- Boost Spiking

- Sudden pressure increases due to delayed wastegate response.

- Solution: Use a high-quality boost controller and properly tune the wastegate actuator.

- Inconsistent Boost Levels

- Caused by leaks in the boost control system.

- Solution: Inspect all hoses, clamps, and fittings for tightness and damage.

Why Boost Control Matters

Efficient boost control unlocks the full potential of your turbocharger while protecting your engine from excessive stress. It allows you to tailor the power delivery to your specific driving needs, whether you’re aiming for a smooth, street-friendly tune or an aggressive track-focused setup.

Internal Engine Upgrades for Durability

When pushing the limits of the 2JZ engine for maximum horsepower, the internal components must be able to handle the added stress and power. Upgrading the internals ensures reliability under high boost, extreme RPMs, and intense conditions.

Reinforcing the Bottom End

The bottom end of the engine (pistons, rods, crankshaft, bearings) is critical for withstanding increased combustion forces.

- Pistons

- Stock pistons can handle ~600-700HP but become a weak point at higher power levels.

- Upgrade to forged pistons for builds exceeding 700HP.

- Brands: CP Pistons, JE Pistons, Wiseco.

- Benefits:

- Withstand higher compression and temperatures.

- Reduce the risk of piston failure under extreme loads.

- Connecting Rods

- Stock rods are strong but should be replaced with forged steel or aluminum rods for power levels above 800HP.

- Brands: Manley, Eagle, Carrillo.

- Benefits:

- Increased tensile strength for high-RPM operation.

- Lighter options reduce reciprocating mass for faster revs.

- Stock rods are strong but should be replaced with forged steel or aluminum rods for power levels above 800HP.

- Crankshaft

- The 2JZ’s stock crankshaft is over-engineered and can handle up to 1,000HP with proper care.

- For extreme builds (~1,500HP+), billet crankshafts are recommended.

- Brands: Brian Crower, Callies.

- Bearings

- Upgrade to performance-grade main and rod bearings to reduce wear under high loads.

- Brands: ACL Race Bearings, King Bearings.

- Upgrade to performance-grade main and rod bearings to reduce wear under high loads.

Cylinder Head Upgrades

Improving airflow in the cylinder head is key to maximizing power and efficiency.

- Porting and Polishing

- Porting increases airflow by enlarging and smoothing intake and exhaust ports.

- Polishing reduces turbulence, enhancing combustion efficiency.

- Valves and Valve Springs

- Stock valves may float at high RPMs, leading to power loss.

- Upgrade to oversized stainless steel or titanium valves for better durability.

- Use dual or beehive valve springs for high-RPM stability.

- Camshafts

- Upgrading camshafts allows for greater valve lift and improved airflow.

- HKS 272° cams are popular for 2JZ builds.

- Adjust cam timing to optimize power delivery at specific RPM ranges.

- Upgrading camshafts allows for greater valve lift and improved airflow.

Gaskets and Head Studs

- Head Gasket

- Replace the stock head gasket with a multi-layer steel (MLS) gasket for better sealing under high boost.

- Thickness depends on compression ratio and power goals.

- Replace the stock head gasket with a multi-layer steel (MLS) gasket for better sealing under high boost.

- Head Studs

- Upgrade to ARP head studs for a more secure cylinder head seal, preventing lift under high pressure.

Oil System Enhancements

Maintaining proper lubrication is vital for preventing damage to upgraded internals.

- High-Flow Oil Pumps

- Upgrade the oil pump to ensure adequate flow at high RPMs.

- Consider using a shimmed oil pump for additional pressure.

- Oil Coolers

- Install an external oil cooler to maintain optimal oil temperature under heavy loads.

- Baffled Oil Pan

- Prevents oil starvation during hard cornering or acceleration.

Balancing and Blueprinting

- Balancing

- Dynamically balance the rotating assembly (crankshaft, pistons, rods) to reduce vibrations and improve reliability.

- Blueprinting

- Ensure all tolerances and clearances are precise, optimizing performance and minimizing wear.

E85 and Compression Ratio Adjustments

- E85 Compatibility

- Running E85 allows for higher compression and boost levels due to its knock-resistant properties.

- Compression Ratio

- Lower compression (~8.5:1 to 9.0:1) is ideal for high-boost applications.

- Higher compression (~10.0:1+) is better for naturally aspirated builds.

Why Internal Upgrades Are Essential

Stock internals are robust but limited when tuning beyond 600HP. Upgrading the engine’s bottom end, cylinder head, and oil system ensures it can handle the stresses of high-performance tuning without sacrificing reliability. Proper reinforcement of these components allows you to confidently push your 2JZ to its full potential.

Cooling System Enhancements

Tuning the 2JZ engine for high horsepower generates significant heat, making an upgraded cooling system essential for maintaining performance and reliability. Proper cooling prevents overheating, which can lead to catastrophic engine failure under high boost and extended operation.

Radiator Upgrades

The stock radiator is not designed to handle the thermal load of a heavily tuned engine.

- Aluminum Performance Radiators

- Lightweight and offer better heat dissipation compared to stock radiators.

- Popular brands: Mishimoto, Koyo, CSF.

- Opt for a dual- or triple-core radiator for maximum cooling efficiency.

- Radiator Cap and Pressure Rating

- Upgrade to a high-pressure radiator cap (e.g., 1.3-1.5 bar) to raise the boiling point of the coolant.

- Helps prevent coolant loss under high-temperature conditions.

Thermostats

- Low-Temperature Thermostats

- Open at lower temperatures (~160°F or 71°C) to circulate coolant sooner.

- Brands like TRD and Mishimoto offer options tailored for performance engines.

- Benefits

- Keeps engine temperatures consistent under heavy loads.

- Reduces the risk of overheating during prolonged use.

Oil Cooling

Oil plays a dual role in lubrication and cooling. As engine power increases, so does the demand for improved oil cooling.

- External Oil Coolers

- Install a high-capacity oil cooler to regulate oil temperature during high RPM or boost.

- Position the cooler in a location with good airflow, such as behind the front bumper.

- Oil Temperature Gauge

- Monitor oil temps to ensure they stay within the optimal range (typically 180°F-210°F).

Intercooler Efficiency

The intercooler is critical for reducing the temperature of the compressed air entering the engine.

- Front-Mount Intercooler (FMIC)

- Larger intercoolers reduce intake air temperatures, resulting in denser air and better combustion.

- Choose a size that matches your turbo and horsepower goals (e.g., 24″x12″x3″).

- Intercooler Placement and Piping

- Use mandrel-bent piping for smooth airflow.

- Avoid excessive piping length, as it can increase turbo lag.

Fan and Shroud Upgrades

- Electric Fans

- Replace the stock mechanical fan with high-performance electric fans for improved cooling efficiency.

- Examples: SPAL and Mishimoto fans.

- Fan Shrouds

- Direct airflow through the radiator for consistent cooling.

- Ensure compatibility with the upgraded radiator and fans.

Coolant Choices

- Performance Coolants

- Use a high-performance coolant (e.g., Evans or Engine Ice) to improve heat transfer and reduce the risk of boiling.

- Water Additives

- Products like Red Line Water Wetter enhance the heat transfer capabilities of water-based coolants.

- Distilled Water Mixes

- For track use, consider a distilled water and additive mix (without antifreeze) for better heat dissipation.

Additional Cooling Enhancements

- Baffled Expansion Tanks

- Prevent air pockets in the cooling system that can cause overheating.

- Improves overall system efficiency.

- Ducting and Airflow Management

- Use cooling ducts to direct airflow to the radiator, intercooler, and oil cooler.

- Proper sealing around these components prevents hot air recirculation.

- Upgraded Water Pumps

- High-flow water pumps improve coolant circulation, especially at high RPMs.

Why Cooling Upgrades Are Essential

As horsepower increases, so does the heat generated by your 2JZ engine. A robust cooling system is critical for maintaining engine health and performance under extreme conditions. Upgraded radiators, intercoolers, and oil coolers work together to dissipate heat effectively, ensuring your engine remains reliable and efficient.

Transmission and Drivetrain Considerations

Tuning the 2JZ engine for maximum horsepower puts immense strain on the transmission and drivetrain. To reliably transfer power to the wheels without failures, these components need to be upgraded and optimized for your specific performance goals.

Clutch and Flywheel Upgrades

The stock clutch and flywheel are not designed to handle the increased torque and horsepower of a tuned 2JZ engine.

- Clutch Options

- Stage 2 or 3 Clutches: Ideal for street builds producing up to 500-700HP.

- Stage 4 or Twin-Disc Clutches: Necessary for high-boost setups exceeding 700HP.

- Brands: Exedy, ACT, SPEC.

- Flywheel Upgrades

- Lightweight flywheels improve throttle response and reduce rotational mass.

- For drag racing, a heavier flywheel may be preferred for smoother launches.

Transmission Strengthening

The Toyota 2JZ is often paired with robust transmissions, but upgrades are essential for extreme horsepower builds.

- R154 Transmission

- Popular for moderate power builds (~600HP).

- Upgrade to billet shift forks, stronger synchros, and heavy-duty input/output shafts for reliability.

- V160/V161 (Getrag 6-Speed)

- The gold standard for high-horsepower 2JZ builds.

- Capable of handling over 1,000HP in stock form but expensive and rare.

- Alternative Options

- CD009 (Nissan 350Z Transmission): Affordable and durable for high-power builds, requiring an adapter plate.

- T56 Magnum: Widely used in drag racing for its strength and availability.

Driveshaft and Axles

High horsepower requires drivetrain components capable of handling increased torque.

- Driveshaft Upgrades

- Replace the stock driveshaft with a single-piece aluminum or carbon fiber unit for reduced weight and increased strength.

- Benefits: Smoother power delivery and less drivetrain loss.

- Axles

- Upgrade to heavy-duty axles (e.g., Driveshaft Shop axles) to prevent breakage during launches.

Differential Upgrades

The rear differential must handle the torque produced by a high-power 2JZ.

- Limited Slip Differentials (LSD)

- Replace the open differential with a mechanical or clutch-type LSD for improved traction.

- Brands: Cusco, Kaaz, OS Giken.

- Replace the open differential with a mechanical or clutch-type LSD for improved traction.

- Final Drive Ratio

- Adjust the gear ratio based on your application:

- Shorter ratios (e.g., 4.10:1) for better acceleration (drag racing).

- Taller ratios (e.g., 3.73:1) for higher top speeds (track use).

- Adjust the gear ratio based on your application:

Upgraded Mounts and Bushings

- Polyurethane or Solid Mounts

- Replace stock mounts with stiffer alternatives to minimize drivetrain flex.

- Benefits: More direct power transfer and improved shifting.

- Drivetrain Bushings

- Upgrading differential and subframe bushings reduces wheel hop and improves handling under high loads.

Traction and Launch Control

High-horsepower builds often struggle with traction during launches or hard accelerations.

- Drag Radials or Performance Tires

- Use tires designed for high grip, such as Mickey Thompson or Toyo R888R.

- Traction Control Systems

- Integrate with your EMS to reduce wheel spin by limiting power delivery to the wheels.

- Two-Step Launch Control

- Allows precise control of RPM during launches, ensuring consistent starts and reduced drivetrain shock.

Common Transmission and Drivetrain Issues

- Clutch Slippage

- Symptoms: Loss of power during acceleration or difficulty shifting.

- Solution: Upgrade to a clutch rated for your horsepower level.

- Driveshaft Vibrations

- Caused by imbalance or improper installation.

- Solution: Ensure the driveshaft is properly aligned and balanced.

- Axle Breakage

- Symptoms: Loud clunks or complete loss of power to one wheel.

- Solution: Install heavy-duty axles designed for high-torque applications.

Why Drivetrain Upgrades Matter

No matter how much power your 2JZ produces, it’s useless if it can’t reach the wheels reliably. Upgrading your transmission, clutch, axles, and differential ensures that your drivetrain can handle the increased torque without failure, making your build as reliable as it is powerful.

Dyno Tuning and Performance Testing

After installing upgrades and making necessary adjustments to your 2JZ engine, dyno tuning is the final step to optimize its performance. This process ensures all components work together efficiently, delivering maximum horsepower and reliability.

What is Dyno Tuning?

Dyno tuning involves using a dynamometer to measure engine output (horsepower and torque) under various load conditions. This data allows precise adjustments to critical parameters like air/fuel ratios, ignition timing, and boost levels.

Preparing for a Dyno Session

Before heading to the dyno, follow these steps to ensure a smooth and productive session:

- Pre-Dyno Checklist

- Verify there are no oil, coolant, or fuel leaks.

- Check that all sensors (wideband O2, MAP, knock) are functioning correctly.

- Ensure proper installation of all aftermarket components (turbo, injectors, etc.).

- Fresh Fluids and Filters

- Use fresh engine oil, coolant, and fuel.

- Replace air and fuel filters to prevent restrictions during tuning.

- Fuel Quality

- Use the same fuel grade or type (e.g., E85, 93-octane) intended for daily operation.

- Baseline Map

- Load a safe baseline map on your ECU to minimize the risk of detonation or lean conditions during initial runs.

Dyno Tuning Process

- Baseline Power Run

- Perform an initial pull to measure current horsepower, torque, and AFR.

- Identify weak points or areas for improvement.

- Adjusting Air/Fuel Ratios (AFR)

- Target an AFR of 11.5:1 to 12:1 for turbocharged setups under boost.

- Lean out the mixture slightly in non-boost regions for better fuel efficiency.

- Optimizing Ignition Timing

- Advance timing cautiously for more power while monitoring for knock.

- Retard timing if knock or detonation occurs.

- Boost Mapping

- Adjust boost levels incrementally to ensure safe power delivery.

- Set boost-by-gear or boost-by-RPM profiles for better control and traction.

- Performance Testing

- Measure and record peak horsepower and torque at various RPMs.

- Compare results with the initial baseline to track progress.

Interpreting Dyno Results

- Horsepower and Torque Curves

- A smooth power curve indicates consistent tuning.

- Identify dips or spikes in the curve, which may signal tuning issues or hardware limitations.

- Air/Fuel Ratio Data

- Confirm that AFR remains consistent and within safe limits across the powerband.

- Boost Pressure Data

- Verify that the turbocharger delivers the desired boost levels without spiking or creeping.

- Knock Monitoring

- Ensure no knock is detected during power pulls, particularly under high boost.

Post-Dyno Adjustments

- Fine-Tuning

- Adjust maps to address any inconsistencies observed during testing.

- Real-World Testing

- Take the car on the road or track to verify drivability and performance under real conditions.

- Logging and Monitoring

- Use the EMS to log additional data during real-world use for further refinements.

Why Dyno Tuning is Essential

Dyno tuning ensures that every upgrade installed on your 2JZ engine operates at its peak potential. By fine-tuning parameters like AFR, timing, and boost, you can achieve maximum horsepower, improved throttle response, and enhanced reliability. Without dyno tuning, even the best upgrades may not deliver optimal results.

Maintenance and Reliability

Once your 2JZ engine is tuned to deliver maximum horsepower, consistent maintenance is critical to ensure its reliability and longevity. High-performance builds endure greater stress, and neglecting maintenance can lead to costly repairs or catastrophic failures.

Regular Maintenance for Tuned Engines

- Oil Changes

- Use high-quality synthetic oil designed for turbocharged or high-performance engines (e.g., 10W-40 or 5W-50).

- Change the oil more frequently, especially after dyno sessions or track days (every 2,000-3,000 miles).

- Coolant System Maintenance

- Regularly inspect coolant levels and ensure no leaks.

- Flush and replace the coolant annually or as recommended by your performance coolant manufacturer.

- Spark Plugs

- Use heat-range-appropriate spark plugs for your power level and boost settings (colder plugs for high boost).

- Inspect and replace spark plugs every 10,000 miles or sooner if fouling occurs.

- Fuel System Checks

- Inspect fuel injectors, lines, and pumps for leaks or clogs.

- Replace fuel filters regularly, especially when using E85, which can degrade components faster.

- Turbocharger Maintenance

- Check for shaft play or oil leaks from the turbo.

- Allow the engine to idle for 1-2 minutes after driving to cool the turbo and prevent oil coking.

Preventative Maintenance for High-Power Builds

- Compression and Leak-Down Tests

- Perform these tests annually to monitor the health of pistons, rings, and valves.

- Address any loss of compression immediately.

- Inspect Belts and Pulleys

- Check the timing belt and accessory belts for wear and replace them according to your build’s intervals.

- Upgrade to a performance timing belt for added durability.

- Monitor AFR and Boost Levels

- Install gauges or use your EMS to continually monitor air/fuel ratios and boost pressure for any abnormalities.

- Exhaust System Maintenance

- Inspect for leaks or cracks, especially around the manifold and downpipe.

- Tighten all clamps and bolts periodically.

Common Issues and Troubleshooting

- Overheating

- Symptoms: Rising coolant temperatures during hard driving or idling.

- Solution: Check radiator, thermostat, and water pump functionality. Upgrade cooling components as needed.

- Detonation or Knocking

- Symptoms: Metallic pinging sound under load.

- Solution: Retard ignition timing, reduce boost, or use higher-octane fuel.

- Oil Consumption or Leaks

- Symptoms: Excessive oil loss or visible leaks.

- Solution: Inspect seals, turbo oil lines, and gaskets. Replace worn components.

- Boost Leaks

- Symptoms: Loss of power or hissing sound under boost.

- Solution: Pressure-test the system to identify and repair leaks in intercooler piping or couplers.

Performance Monitoring Tools

- Data Loggers

- Use EMS-integrated logging tools to track performance data like AFR, knock, and boost pressure over time.

- Diagnostics Tools

- OBD-II scanners and standalone EMS diagnostics can help identify issues early.

- Gauges

- Essential gauges to monitor: oil pressure, boost, AFR, and coolant temperature.

Scheduled Maintenance Checklist for Tuned 2JZ Engines

| Maintenance Task | Interval |

| Oil and filter change | Every 2,000-3,000 miles |

| Spark plug inspection/replacement | Every 10,000 miles or sooner |

| Coolant flush | Annually |

| Timing belt inspection | Every 60,000 miles (or upgraded intervals) |

| Compression test | Annually |

| Turbocharger inspection | Annually or after track use |

Why Maintenance is Essential

Tuning your 2JZ for maximum horsepower significantly increases the strain on its components. Consistent maintenance not only ensures reliability and performance but also protects your investment. Proactive care minimizes the risk of expensive failures, keeping your 2JZ running strong for years to come.

Legal and Environmental Considerations

When tuning a 2JZ engine for maximum horsepower, it’s important to consider legal and environmental regulations. Compliance with emissions and noise standards ensures your build is both roadworthy and respectful of community standards. Neglecting these factors could lead to fines, restrictions, or even bans on vehicle operation in certain areas.

Emissions Compliance

- Catalytic Converters

- Retaining or upgrading to a high-flow catalytic converter helps reduce harmful emissions while maintaining performance.

- Legal requirements in many regions mandate the use of catalytic converters for road-driven vehicles.

- Emission Testing

- Ensure your build passes local emissions testing.

- For turbocharged setups, tuning the AFR to run slightly leaner during idle and low load can help reduce emissions without sacrificing power.

- E85 and Ethanol Fuels

- E85 can significantly reduce carbon emissions while offering higher octane levels.

- Verify local availability of E85 and ensure your fuel system is ethanol-compatible.

Noise Regulations

- Exhaust Noise Levels

- Many regions enforce limits on exhaust noise. Install a muffler or resonator to comply with noise ordinances.

- Consider using a variable exhaust system (e.g., a valve-controlled exhaust) that allows you to switch between quieter and louder modes.

- Blow-Off Valve Noise

- Atmospheric blow-off valves produce the signature “whoosh” sound, which may be restricted in some areas.

- Opt for recirculating blow-off valves for a quieter, more discreet setup.

Street vs. Track Use

- Dedicated Track Builds

- Vehicles used solely on the track may be exempt from emissions and noise regulations in most regions.

- Consult local laws regarding off-road-only vehicles to ensure compliance.

- Street-Legal Builds

- Balance performance with compliance by using emission-legal parts, quieter exhaust systems, and professional tuning for optimal drivability.

Registration and Inspection

- Modified Vehicle Inspections

- Some regions require modified vehicles to pass additional safety and emissions inspections.

- Keep documentation of all modifications, including part certifications and dyno results.

- Title and Registration

- Check your local Department of Motor Vehicles (DMV) or equivalent agency for rules regarding modified vehicles.

- Vehicles with significant modifications may require reclassification or special permits.

Insurance Considerations

- Specialty Insurance

- Insurers may require full disclosure of engine and drivetrain modifications.

- Look for companies specializing in high-performance or modified vehicle coverage.

- Valuation of Modifications

- Document all upgrades with receipts and photographs to ensure they are included in the insured value of your vehicle.

Environmental Responsibility

- Reducing Carbon Footprint

- Use cleaner fuels (e.g., E85 or low-carbon racing fuels).

- Maintain a properly tuned engine to optimize fuel efficiency and minimize emissions.

- Proper Disposal of Fluids and Parts

- Dispose of used oil, coolant, and other fluids at certified recycling centers.

- Recycle old parts like catalytic converters, batteries, and radiators responsibly.

Penalties for Non-Compliance

Non-compliance with legal and environmental regulations can result in:

- Fines and penalties for emissions or noise violations.

- Suspension of vehicle registration or operating privileges.

- Impounding of your vehicle in extreme cases.

Balancing Performance and Compliance

Building a high-performance 2JZ engine doesn’t mean sacrificing compliance. By selecting emissions-friendly upgrades, using quieter exhaust systems, and staying informed about local regulations, you can enjoy the thrill of a powerful engine while staying street-legal and environmentally responsible.

Conclusion

Building and tuning a 2JZ engine for maximum horsepower is both an art and a science. The process requires careful planning, precise execution, and a commitment to balancing raw power with reliability. By following this comprehensive guide, you now have the knowledge and roadmap needed to transform your 2JZ into a high-performance powerhouse.

Key Takeaways

- Understand the Engine

- The 2JZ’s robust design makes it an ideal platform for high-horsepower builds, but each variant (2JZ-GE, 2JZ-GTE) requires specific approaches for tuning.

- Upgrade Strategically

- Prioritize upgrades based on your power goals, starting with intake, exhaust, fuel system, and turbocharging.

- Fine-Tune for Performance

- Use advanced tools like standalone ECUs and wideband O2 sensors to optimize air/fuel ratios, ignition timing, and boost control.

- Reinforce for Reliability

- Strengthen internal components, cooling systems, and the drivetrain to handle the increased stress of a tuned engine.

- Maintain Consistently

- Regular maintenance is critical to ensure your 2JZ performs reliably for years to come.

Final Thoughts

The 2JZ engine has earned its legendary status for a reason. With the right combination of parts, tuning, and expertise, it can produce staggering horsepower figures while maintaining everyday usability. Whether you’re building a track monster, a drag racer, or a street machine, the principles and steps outlined in this guide will help you achieve your performance goals.

Call to Action

If you’ve found this guide helpful, share it with fellow enthusiasts or leave a comment with your experiences and results. For more 2JZ tuning insights, updates, and tips, subscribe to our blog and follow us on social media. Let’s keep pushing the limits of what this iconic engine can achieve! 🚗🔥

Frequently Asked Questions (FAQs)

How much horsepower can a stock 2JZ handle?

The stock 2JZ-GTE engine is known for its durability and can handle 600-700 horsepower on factory internals with proper tuning. For the naturally aspirated 2JZ-GE, the limit is closer to 400-450 horsepower. Achieving higher power levels requires upgrading components such as pistons, rods, and head gaskets to withstand the increased stress. Regular maintenance and careful tuning are essential to ensure reliability at these power levels.

What turbo size is ideal for my 2JZ build?

The ideal turbo size depends on your power goals and intended use:

- Small Turbo (50-60mm): Great for street builds targeting ~400-500HP. Provides quick spool and better low-RPM drivability.

- Medium Turbo (60-70mm): Balanced for street and track use, capable of producing ~600-800HP.

- Large Turbo (70mm+): Best for drag racing or extreme builds exceeding 1,000HP, but may introduce turbo lag.

Selecting the right turbocharger also involves considering supporting modifications, such as fuel system upgrades, intercooler size, and drivetrain enhancements.

What’s the best fuel for a high-performance 2JZ?

The fuel you choose significantly impacts tuning and performance:

- Pump Gasoline (93-Octane): Suitable for moderate power builds (~400-500HP).

- E85 Ethanol: Offers a higher octane rating and cooling properties, enabling more aggressive timing and higher boost levels. However, it requires upgraded injectors, fuel pumps, and ethanol-compatible lines.

- Race Fuel (100+ Octane): Ideal for high-power builds (~800HP+), providing superior knock resistance for maximum boost and timing.

For daily driving or occasional performance use, E85 is a popular choice due to its accessibility and cost-effectiveness.

How do I prevent detonation when tuning a 2JZ engine?

Detonation, or knock, is one of the biggest threats to a tuned engine. Here are key steps to prevent it:

- Proper AFR Tuning: Maintain an air/fuel ratio of 11.5:1 to 12:1 under boost to avoid lean conditions.

- Control Ignition Timing: Retard ignition timing under high boost to reduce cylinder pressure and prevent pre-ignition.

- Use High-Octane Fuel: Higher octane fuels resist knock better, allowing for more aggressive tuning.

- Monitor Engine Conditions: Use knock sensors, AFR gauges, and real-time data logging to identify and resolve issues early.

- Cooling Upgrades: Install larger radiators, intercoolers, and oil coolers to manage heat buildup during aggressive tuning.

Can I turbocharge a 2JZ-GE engine, and what’s required?

Yes, the 2JZ-GE can be turbocharged to achieve impressive power levels, but it requires specific modifications:

- Turbo Kit: Install a bolt-on turbo kit or custom setup, including a turbocharger, exhaust manifold, downpipe, and intercooler.

- Fuel System: Upgrade fuel injectors, fuel pump, and pressure regulator to handle the increased fuel demand.

- ECU or EMS: Use a piggyback or standalone engine management system to tune for proper air/fuel ratios and ignition timing.

- Internal Upgrades: For power levels exceeding ~400HP, consider upgrading pistons, rods, and head gaskets to handle the added stress.

- Cooling System: Add an oil cooler and radiator upgrades to manage heat from forced induction.

With these modifications and proper tuning, a turbocharged 2JZ-GE can reliably produce 500-700 horsepower.