The Toyota 2JZ engine has achieved legendary status among car enthusiasts and performance tuners. Known for its durability, incredible power potential, and reliable engineering, this iconic inline-six engine has become a favorite in the automotive world. Originally equipped with a twin-turbo configuration in the 2JZ-GTE model, the engine offers impressive performance right out of the factory.

However, for many enthusiasts, the allure of converting the 2JZ to a single turbo setup is irresistible. This modification unlocks a new level of customization, power, and efficiency, making it a popular choice for those looking to maximize their engine’s potential.

This comprehensive guide aims to provide a step-by-step walkthrough of upgrading your 2JZ engine from a twin-turbo setup to a single turbo. Along the way, we’ll explore the advantages of going single, key considerations before starting the project, and essential tips to ensure a successful conversion.

Whether you’re building a track car, a high-performance daily driver, or a drag racing beast, this article will equip you with the knowledge to make informed decisions and achieve outstanding results. Let’s dive into the world of single turbo conversions and discover how to take your 2JZ to the next level.

Understanding the Basics of Turbocharging in the 2JZ

What is Turbocharging?

Turbocharging is a method of forced induction that compresses the air entering the engine, allowing for a greater amount of fuel and air to combust in each cylinder. This results in significantly increased power output compared to naturally aspirated engines. The Toyota 2JZ-GTE, as a factory-installed twin-turbocharged engine, is a shining example of how turbocharging can unlock exceptional performance.

The Twin-Turbo Setup in the 2JZ-GTE

The 2JZ-GTE’s twin-turbo configuration is designed for sequential turbocharging, where one smaller turbo operates at low RPM for improved responsiveness, and the second larger turbo engages at higher RPM to maximize power. This system ensures:

- Smooth power delivery across a wide RPM range.

- Enhanced low-end torque for daily drivability.

- High-end power output for performance needs.

However, the complexity of the twin-turbo system comes with limitations, such as:

- Increased weight and space requirements.

- More components prone to wear and failure.

- Limited customization for higher power goals.

Why Go Single Turbo?

While the stock twin-turbo system is efficient for its intended purpose, a single turbo setup offers unparalleled flexibility for tuners. By replacing the twin turbos with a larger, more efficient single turbocharger, enthusiasts can achieve:

- Higher peak power outputs.

- Simplified plumbing and reduced engine bay clutter.

- A tailored setup optimized for specific performance goals.

With a solid understanding of turbocharging fundamentals and the factory twin-turbo setup, we can now explore the benefits of converting your 2JZ engine to a single turbo configuration.

Advantages of Converting to a Single Turbo

Switching from a twin-turbo setup to a single turbo configuration on the 2JZ engine offers several compelling benefits, making it a popular choice among performance enthusiasts. Here’s a detailed breakdown of the key advantages:

1. Performance Gains

A single turbocharger can produce higher peak power outputs compared to a twin-turbo system. With the ability to choose a turbo tailored to your performance goals, a single turbo setup can:

- Deliver significant horsepower and torque increases, especially at higher RPM ranges.

- Handle greater boost levels due to improved efficiency and design.

For example, a properly sized single turbo can push a 2JZ engine to exceed 700 HP or more, depending on supporting modifications.

2. Simplified Design

The single turbo system offers a cleaner and more streamlined design compared to the factory twin-turbo setup. This simplification provides:

- Reduced complexity: Fewer components mean fewer potential failure points.

- Easier maintenance and troubleshooting: A single turbo is easier to access and service than a dual-turbo configuration.

- Improved airflow efficiency: With fewer pipes and junctions, the intake and exhaust systems face less restriction.

3. Customization Flexibility

One of the greatest advantages of a single turbo setup is the ability to customize the system to your needs:

- Choose the ideal turbo size based on your desired power band (e.g., larger turbos for top-end power or smaller ones for reduced lag).

- Use aftermarket manifolds, downpipes, and wastegates tailored to your application.

- Integrate advanced boost control systems for precise tuning.

This level of flexibility allows tuners to optimize their setup for street use, track performance, or drag racing.

4. Cost Efficiency

While the initial conversion cost may be high, a single turbo setup often results in lower maintenance costs over time:

- Fewer components to maintain or replace.

- Easier upgrades, as most performance parts are designed for single turbo systems.

- The ability to repurpose parts across different builds or projects.

5. Enhanced Aesthetics and Engine Bay Space

The streamlined nature of a single turbo system creates a cleaner engine bay appearance, providing:

- Easier access to other components for repairs or modifications.

- Reduced weight in the engine bay, which can contribute to better handling and balance.

6. Increased Tuning Potential

A single turbo setup is often more compatible with standalone ECUs and modern tuning methods. This allows for:

- Greater control over air-fuel ratios, ignition timing, and boost levels.

- Advanced features like anti-lag systems and boost-by-gear for track or racing applications.

Converting to a single turbo setup unlocks incredible performance potential while offering simplicity, flexibility, and long-term cost benefits. These advantages make it a worthwhile investment for anyone looking to take their 2JZ engine to the next level.

Considerations Before Converting to a Single Turbo

Switching to a single turbo setup on your 2JZ engine is a transformative upgrade, but it requires careful planning to ensure a successful and efficient conversion. Here are key factors to consider before starting your project:

1. Budget Planning

Converting to a single turbo setup can range from a modest upgrade to a high-budget build, depending on the quality and scope of components. Key costs to account for include:

- Turbo Kit: Prices can vary significantly based on the turbo brand, size, and quality.

- Supporting Modifications: Fuel system upgrades, standalone ECU, intercooler, and piping.

- Labor Costs: Professional installation fees, if you’re not doing the work yourself.

- Tuning: Essential to optimize performance and ensure engine longevity.

Tip: Create a detailed budget that includes a buffer for unexpected expenses.

2. Technical Expertise

A single turbo conversion requires a good understanding of engine mechanics and turbo systems. Assess your skill level honestly:

- If you’re a seasoned DIYer, ensure you have the tools and workspace for the project.

- For less experienced enthusiasts, hiring a professional mechanic or tuner is recommended to avoid costly mistakes.

3. Intended Vehicle Use

Your driving habits and goals should influence your turbo selection and setup:

- Daily Driving: Prioritize a smaller turbo for reduced lag and better drivability.

- Track Use: Focus on a balance between responsiveness and peak power.

- Drag Racing: Opt for a larger turbo for maximum top-end performance.

Tip: Clearly define your primary use case to guide your component selection.

4. Legal and Emissions Compliance

Modifying your engine’s turbo system can have legal implications in some regions:

- Emissions Standards: A single turbo setup may not comply with emissions regulations, particularly if the vehicle lacks catalytic converters or OEM components.

- Inspections and Certifications: Ensure your modifications meet local laws to avoid fines or penalties.

Tip: Research regulations in your area before proceeding with the conversion.

5. Supporting Modifications

To achieve the full potential of a single turbo setup, additional upgrades are often necessary:

- Fuel System: Larger injectors, high-flow fuel pumps, and regulators to support increased power.

- Cooling System: Upgraded intercoolers and radiators to manage higher heat levels.

- Exhaust System: A free-flowing exhaust to reduce backpressure and optimize performance.

- Standalone ECU: For precise tuning and control over the engine.

Tip: Include these upgrades in your project timeline and budget.

6. Time Commitment

A single turbo conversion is a time-intensive process, particularly if you’re doing it yourself. Tasks such as removing the twin turbos, fitting the new turbo, and connecting supporting components require patience and precision.

7. Long-Term Maintenance

While a single turbo system simplifies certain aspects of the engine, it introduces new maintenance considerations:

- Turbo Maintenance: Regular inspections for shaft play, oil leaks, and boost control.

- Tuning Updates: Periodic adjustments to keep the engine running optimally.

By addressing these considerations upfront, you can streamline the conversion process and minimize unexpected setbacks. This thoughtful preparation will help you enjoy the performance gains of your single turbo 2JZ with confidence.

Components Needed for a Single Turbo Conversion

Converting your 2JZ engine to a single turbo setup requires a well-thought-out selection of components. Each part plays a crucial role in ensuring reliability, performance, and compatibility. Here’s a breakdown of the essential components you’ll need:

1. Turbocharger

The heart of the single turbo setup, your turbo choice determines the overall performance characteristics of your engine.

- Key Considerations:

- Size: Larger turbos provide high-end power but may introduce lag. Smaller turbos offer quicker spool times, ideal for street use.

- Brands: Garrett, Precision, BorgWarner, and Holset are popular and reliable options.

- Compressor and Turbine Trim: Match the turbo’s airflow characteristics to your power goals.

- Example Options:

- Garrett GTX3582R: Excellent for 500–700 HP builds.

- Precision 6466: Ideal for high-power drag setups.

2. Turbo Manifold

The turbo manifold connects the exhaust gases from the engine to the turbocharger.

- Options:

- Log Style: Budget-friendly and compact.

- Equal Length: Optimized for performance, offering balanced exhaust flow.

- Material: Stainless steel is preferred for durability and heat resistance.

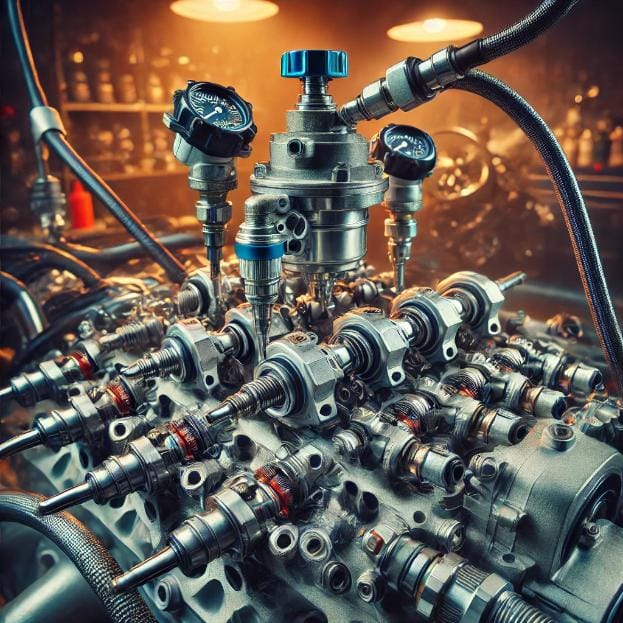

3. Fuel System Upgrades

A single turbo setup demands more fuel to match the increased airflow.

- Components:

- Fuel Injectors: Larger injectors (e.g., 1,000cc or higher) to handle increased fuel requirements.

- Fuel Pump: High-flow pumps like the Walbro 450 or AEM 380.

- Fuel Pressure Regulator: Ensures consistent fuel delivery under boost.

4. Standalone ECU

A standalone engine control unit (ECU) is essential for precise tuning and control.

- Top Choices:

- Haltech Elite 2000

- AEM Infinity

- Link G4+

- Functions:

- Boost control, air-fuel ratio (AFR) monitoring, ignition timing adjustment.

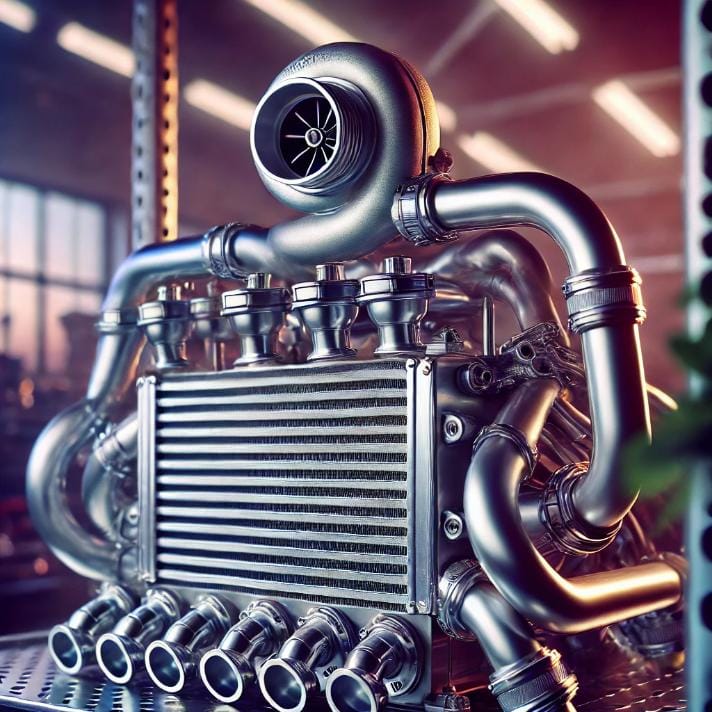

5. Intercooler and Piping

The intercooler cools the compressed air from the turbo before it enters the engine.

- Options:

- Front-Mount Intercooler (FMIC): Most common for high-performance setups.

- Bar-and-Plate Design: Preferred for durability and cooling efficiency.

- Piping:

- Aluminum or stainless steel for strength and heat dissipation.

- Proper couplers and clamps to ensure a leak-free setup.

6. Exhaust System

A free-flowing exhaust is critical for turbo efficiency.

- Components:

- Downpipe: Connects the turbo to the exhaust. Ensure it matches the turbo’s outlet.

- Exhaust Diameter: 3-inch or larger for high-flow setups.

- Catalytic Converter (Optional): Depending on emissions requirements.

7. Oil and Coolant Lines

Turbochargers require dedicated oil and coolant lines for lubrication and cooling.

- Options:

- Braided steel lines for durability and heat resistance.

- AN fittings for secure connections.

8. Wastegate and Blow-Off Valve (BOV)

These components help regulate boost pressure and protect the turbo system.

- Wastegate:

- External: Offers better control for high-boost setups.

- Popular Brands: Tial, Turbosmart.

- Blow-Off Valve (BOV):

- Releases excess pressure to prevent compressor surge.

9. Boost Controller

Controls the amount of boost generated by the turbo.

- Options:

- Manual controllers: Cost-effective but less precise.

- Electronic controllers: Advanced control with settings for different driving modes.

10. Miscellaneous Components

- Turbo Mounting Hardware: Bolts, gaskets, and brackets.

- Heat Management:

- Turbo blankets and heat wrap for exhaust piping to manage engine bay temperatures.

- Gaskets and Seals:

- High-quality gaskets for exhaust and intake connections.

Optional Components

- Water-Methanol Injection:

- Reduces intake air temperatures and prevents detonation under high boost.

- Surge Tank:

- Helps prevent fuel starvation during aggressive driving.

By gathering these components, you’ll have the foundation needed for a successful single turbo conversion. In the next section, we’ll dive into the step-by-step installation process, guiding you

Detailed Conversion Process: Step-by-Step Guide

Switching to a single turbo on your 2JZ engine is a detailed project that requires patience, precision, and the right tools. Here’s a comprehensive step-by-step guide to help you successfully complete the conversion:

1. Preparation

Tools and Equipment:

- Socket sets, wrenches, and torque wrenches.

- Engine hoist (if necessary).

- Safety gear: gloves, goggles, and fire extinguisher.

Work Area:

- Ensure a clean, well-lit, and organized workspace.

- Have a friend or professional on standby for assistance.

Checklist:

- Verify that you have all components (refer to the previous section).

- Drain fluids (coolant and oil) to avoid spills during disassembly.

2. Removing the Twin-Turbo System

- Step 1: Disconnect the battery to ensure safety.

- Step 2: Remove the air intake, intercooler piping, and stock exhaust system.

- Step 3: Carefully unbolt the twin turbos from the exhaust manifold.

- Step 4: Disconnect oil and coolant lines attached to the twin turbos.

- Step 5: Remove the stock turbo manifold.

Tips:

- Label bolts and small components for easier reassembly.

- Inspect the engine bay for wear, leaks, or damage before proceeding.

3. Installing the Single Turbo

- Step 1: Mount the new turbo manifold. Ensure proper alignment and use quality gaskets.

- Step 2: Attach the single turbo to the manifold using high-grade bolts.

- Step 3: Connect oil feed and return lines, ensuring they are properly routed and free of kinks.

- Step 4: Install coolant lines if your turbo requires water cooling.

- Step 5: Attach the wastegate to the manifold and connect the appropriate lines.

Pro Tip: Pre-lubricate the turbo with engine oil before starting the installation.

4. Installing Supporting Components

- Intercooler and Piping:

- Mount the intercooler securely in the front of the vehicle.

- Connect intercooler piping to the turbo and throttle body using clamps and couplers.

- Exhaust System:

- Install the downpipe and connect it to the exhaust system.

- Ensure proper clearance to avoid rattling or damage during operation.

- Fuel System:

- Upgrade injectors, fuel pump, and pressure regulator as needed.

- Double-check for leaks after installation.

- ECU and Wiring:

- Install the standalone ECU and connect sensors (boost, AFR, etc.).

- Program the ECU with a base map for the single turbo setup.

5. Tuning and Initial Start-Up

- Step 1: Perform a thorough visual inspection to ensure all components are securely installed.

- Step 2: Refill engine oil and coolant.

- Step 3: Start the engine and let it idle to check for leaks or unusual noises.

- Step 4: Conduct a low-boost test run to ensure proper operation of the turbo and wastegate.

- Step 5: Schedule a professional dyno tune to optimize power and reliability.

6. Fine-Tuning and Testing

- Boost Control:

- Adjust boost levels to suit your desired performance and the turbo’s capacity.

- Air-Fuel Ratios (AFR):

- Monitor AFR to ensure safe engine operation under different driving conditions.

- Heat Management:

- Verify that heat wraps, turbo blankets, and cooling systems are effectively managing temperatures.

7. Post-Conversion Maintenance

- Regular Inspections:

- Check turbo components for wear, leaks, or loose connections.

- Scheduled Tuning:

- Retune the ECU periodically to maintain peak performance.

- Oil Changes:

- Follow a strict oil change schedule, especially with higher boost levels.

Completing the single turbo conversion on your 2JZ engine is a rewarding experience that delivers outstanding performance gains. With proper installation, tuning, and maintenance, your engine will be ready to handle the power and thrill of a single turbo setup.

Common Issues and Troubleshooting

Even with meticulous planning and execution, challenges may arise during or after a single turbo conversion on your 2JZ engine. This section outlines common issues you might encounter and provides practical solutions to address them effectively.

1. Boost Creep

What It Is: Boost creep occurs when the wastegate cannot effectively control exhaust flow, leading to unintended and excessive boost levels.

Causes:

- Undersized wastegate.

- Poorly designed turbo manifold.

- Excessive exhaust gas flow.

Solutions:

- Upgrade to a larger external wastegate (e.g., 44mm or larger).

- Ensure proper placement of the wastegate on the manifold.

- Check and adjust the wastegate spring or boost controller settings.

2. Turbo Lag

What It Is: Turbo lag is the delay in power delivery caused by the time it takes for the turbo to spool up.

Causes:

- Oversized turbocharger.

- Inefficient boost control setup.

- Long intercooler piping causing pressure drop.

Solutions:

- Choose a smaller or twin-scroll turbo for quicker spooling.

- Optimize intercooler piping for shorter and more direct airflow.

- Adjust the boost controller for better responsiveness.

3. Overheating

What It Is: Excessive heat can lead to engine damage and reduced turbo efficiency.

Causes:

- Insufficient cooling system capacity.

- Poor heat management in the engine bay.

- Excessive boost without proper tuning.

Solutions:

- Upgrade the radiator, fans, and oil cooler.

- Use turbo blankets and heat wraps on exhaust components.

- Ensure proper air-fuel ratios (AFR) through tuning.

4. Oil Leaks

What It Is: Oil leaks can occur around the turbocharger, causing reduced lubrication and potential damage.

Causes:

- Incorrectly routed oil lines.

- Loose fittings or gaskets.

- Excessive crankcase pressure.

Solutions:

- Use high-quality braided oil lines and AN fittings.

- Inspect and replace gaskets if necessary.

- Install a catch can or breather to manage crankcase pressure.

5. Poor Tuning

What It Is: Inadequate tuning can result in poor engine performance, detonation, or even catastrophic failure.

Causes:

- Using a generic or outdated ECU map.

- Inaccurate sensor data.

- Insufficient dyno tuning.

Solutions:

- Invest in a professional dyno tune tailored to your setup.

- Regularly update your standalone ECU software.

- Ensure all sensors (e.g., AFR, boost, IAT) are calibrated and functioning correctly.

6. Compressor Surge

What It Is: A sudden reversal of airflow when the throttle closes, causing the turbo to stall.

Causes:

- Missing or malfunctioning blow-off valve (BOV).

- Incorrectly sized BOV.

Solutions:

- Install a high-quality BOV and ensure it is properly adjusted.

- Verify that the BOV is compatible with your turbo system.

7. Exhaust Backpressure

What It Is: Excessive backpressure in the exhaust system can hinder turbo efficiency and reduce power output.

Causes:

- Undersized exhaust piping.

- Restrictions in the catalytic converter or muffler.

Solutions:

- Use a 3-inch or larger diameter exhaust system.

- Consider a high-flow catalytic converter or a straight-pipe setup (if regulations permit).

8. Fuel Delivery Issues

What It Is: Insufficient fuel supply can lead to lean conditions, causing engine damage.

Causes:

- Undersized injectors or fuel pump.

- Inconsistent fuel pressure.

Solutions:

- Upgrade to high-flow fuel injectors and a compatible fuel pump.

- Install a reliable fuel pressure regulator.

9. Vibrations or Mounting Problems

What It Is: Improperly mounted components can lead to vibrations, noise, and premature wear.

Causes:

- Loose bolts or poorly designed mounts.

- Misaligned turbo or piping.

Solutions:

- Use high-quality mounting brackets and torque all bolts to spec.

- Double-check alignment during installation.

10. Emissions Compliance Challenges

What It Is: Modified turbo setups may fail emissions tests in certain regions.

Causes:

- Absence of a catalytic converter.

- Increased exhaust emissions due to high boost levels.

Solutions:

- Install a high-flow catalytic converter.

- Optimize tuning to minimize emissions.

Preventative Maintenance Tips

- Routine Inspections: Check all components periodically for wear, leaks, and proper operation.

- Regular Oil Changes: Use high-quality synthetic oil and follow a strict oil change schedule.

- Monitor Sensors: Keep an eye on AFR, boost, and temperature readings to catch issues early.

This troubleshooting guide will help you address common challenges and ensure your single turbo 2JZ setup performs reliably and efficiently.

Case Studies and Examples

To provide a clearer understanding of the potential outcomes and variations in single turbo conversions, here are two real-world examples: a budget-friendly build and a high-performance setup. These examples highlight the flexibility and adaptability of the 2JZ single turbo conversion.

1. Budget Build: Affordable Single Turbo Setup

Objective: Achieving a reliable and cost-effective single turbo setup for street use.

Build Highlights:

- Turbo: CX Racing budget single turbo kit (~$650).

- Manifold: Log-style manifold included in the kit.

- Fuel System: Upgraded to 550cc injectors and a Walbro 255 fuel pump.

- Intercooler: Affordable front-mount intercooler (~$300).

- ECU: Piggyback ECU (Greddy E-Manage) for basic tuning.

- Exhaust: Custom 3-inch downpipe and cat-back exhaust.

Performance Results:

- Peak Power: 400-450 HP at 14 PSI.

- Driveability: Smooth power delivery for daily driving.

- Cost: Total conversion cost under $3,000.

Pros:

- Affordable and straightforward setup.

- Reliable for moderate power goals.

- Ideal for beginners with basic mechanical skills.

Cons:

- Limited room for future upgrades.

- Piggyback ECU lacks advanced tuning features.

2. High-Performance Build: Drag-Focused Single Turbo Setup

Objective: Maximizing horsepower for competitive drag racing.

Build Highlights:

- Turbo: Precision 6466 ball-bearing turbo (~$2,300).

- Manifold: Equal-length stainless steel manifold for optimal flow.

- Fuel System: 1,000cc injectors, dual Walbro 450 fuel pumps, and a surge tank.

- Intercooler: High-capacity bar-and-plate front-mount intercooler.

- ECU: Haltech Elite 2000 standalone ECU for advanced tuning.

- Exhaust: 4-inch straight pipe for maximum flow.

- Additional Upgrades:

- Anti-lag system for quicker spool.

- Methanol injection for cooler intake temps and detonation prevention.

Performance Results:

- Peak Power: 850+ HP at 30 PSI.

- Quarter-Mile Time: Low 10-second range.

- Cost: Total conversion cost over $10,000.

Pros:

- Exceptional power and performance.

- Advanced ECU enables fine-tuning for every aspect of the setup.

- Suitable for competitive use.

Cons:

- High initial cost and maintenance requirements.

- Turbo lag more noticeable in street driving.

Comparison of Builds

| Feature | Budget Build | High-Performance Build |

| Turbo | CX Racing Single Turbo | Precision 6466 |

| Fuel System | 550cc injectors, Walbro 255 | 1,000cc injectors, Dual Walbro 450 |

| ECU | Greddy E-Manage | Haltech Elite 2000 |

| Peak Power | 400-450 HP | 850+ HP |

| Cost | ~$3,000 | ~$10,000 |

Lessons Learned from Case Studies

- Budget Builds: Ideal for enthusiasts looking to improve performance on a tight budget without aiming for extreme horsepower figures.

- High-Performance Builds: Best for those seeking maximum power and flexibility for competitive use, but requires a significant investment in time, money, and expertise.

These case studies demonstrate the range of possibilities available with a single turbo conversion on the 2JZ engine, catering to both casual enthusiasts and hardcore tuners.

FAQs: Common Questions About Single Turbo Conversion

To provide clarity on common concerns and inquiries about single turbo conversions on the 2JZ engine, here are detailed answers to frequently asked questions:

What are the benefits of a single turbo over twin turbos?

- Higher Power Potential: Single turbos can handle greater airflow and boost levels, making them ideal for high horsepower builds.

- Simplified Design: A single turbo reduces complexity, resulting in easier maintenance and a cleaner engine bay.

- Customization: You can choose a turbo specifically tailored to your performance goals, whether it’s quick spool for street use or maximum power for racing.

How much does it cost to install a single turbo on a 2JZ?

The cost depends on your goals and parts selection:

- Budget Build: ~$3,000 for basic components and a DIY installation.

- High-Performance Build: $10,000+ for premium components, professional installation, and tuning.

- Additional expenses may include supporting modifications such as fuel system upgrades, standalone ECU, and dyno tuning.

What parts are needed for a 2JZ single turbo conversion?

Key components include:

- Turbocharger and manifold.

- Fuel system upgrades (injectors, fuel pump, regulator).

- Standalone ECU or piggyback system.

- Intercooler and piping.

- Exhaust system and downpipe.

- Oil and coolant lines.

- Wastegate and blow-off valve.

Refer to the “Components Needed” section for a detailed breakdown.

How difficult is a single turbo conversion?

The difficulty varies based on your mechanical experience:

- Moderate: For those familiar with engine modifications, the project is manageable with the right tools and resources.

- Challenging: Beginners may find it overwhelming due to the need for precision in tuning and component installation. Professional assistance is recommended in such cases.

What turbo size should I choose for my 2JZ?

Your turbo choice depends on your goals:

- Smaller Turbos: Faster spool, ideal for daily driving and responsive street setups (e.g., Garrett GTX3076R).

- Larger Turbos: Higher peak power, suited for drag racing or track use (e.g., Precision 6466).

- Consult a professional tuner to match the turbo to your desired power range and driving style.

Do I need a standalone ECU for a single turbo conversion?

Yes, a standalone ECU is highly recommended to:

- Manage air-fuel ratios, ignition timing, and boost control.

- Prevent engine damage and maximize performance. Popular options include Haltech Elite 2000, AEM Infinity, and Link G4+.

How does a single turbo affect daily drivability?

- Pros: Cleaner engine bay, simplified maintenance, and customizable power delivery.

- Cons: Larger turbos may introduce noticeable lag, making them less suitable for daily use. Proper tuning and turbo sizing can mitigate these drawbacks.

What is the expected power output from a single turbo 2JZ?

- Mild Build: 400-500 HP at 14-16 PSI with a budget turbo kit.

- High-Performance Build: 700-1,000+ HP at 25-30 PSI with premium components and supporting mods.

How can I reduce turbo lag in a single turbo setup?

- Use a twin-scroll turbocharger.

- Optimize intercooler piping for shorter routes.

- Adjust boost controller settings for quicker spool.

- Incorporate anti-lag systems in high-performance applications.

Is emissions compliance a concern with a single turbo setup?

In regions with strict emissions regulations, a single turbo setup may not pass inspections due to increased exhaust emissions or lack of a catalytic converter. Consider installing a high-flow catalytic converter and ensure proper tuning to minimize emissions.

Conclusion

Converting your 2JZ engine from a twin-turbo to a single turbo setup is a rewarding modification that unlocks unparalleled performance, customization, and simplicity. By following this guide, you can confidently plan and execute the conversion, ensuring your build aligns with your goals and budget.

Whether you’re aiming for a budget-friendly upgrade or a high-powered track beast, the single turbo setup provides the flexibility to achieve your vision. With proper tuning, maintenance, and attention to detail, your 2JZ engine will deliver thrilling performance and a driving experience that stands out.