How to Check the ECM Power Source Circuit in the 2JZ-GTE Engine

The 2JZ-GTE engine, renowned for its power and reliability, is a favorite among car enthusiasts. Central to its performance is the Engine Control Module (ECM), which relies on a stable power source to function correctly. The ECM power source circuit is crucial for the overall operation of the engine, ensuring that it receives the necessary electrical power to manage various engine functions.

Understanding and checking the ECM power source circuit in the 2JZ-GTE engine is vital for maintaining its optimal performance. This article will guide you through the significance of the ECM power source circuit, common issues that may arise, and detailed diagnostic and troubleshooting procedures. By mastering these aspects, you can ensure that your 2JZ-GTE engine remains in peak condition.

Understanding the ECM Power Source Circuit

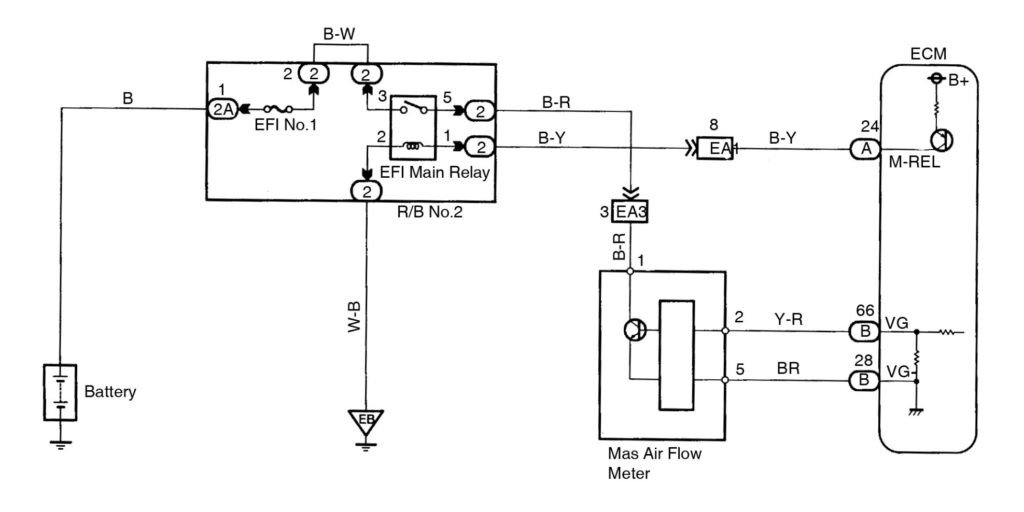

Function: The ECM power source circuit is responsible for supplying the necessary electrical power to the Engine Control Module. The ECM uses this power to monitor and control various engine functions, including fuel injection, ignition timing, and emissions control. A stable and reliable power source is essential for the ECM to perform these tasks efficiently.

Components: The main components of the ECM power source circuit include the battery, fuses, wiring, and connectors. The battery provides the primary power, while fuses protect the circuit from overloads. Wiring and connectors ensure the efficient transmission of electrical power to the ECM.

Importance: A properly functioning ECM power source circuit is crucial for the engine’s performance. Any disruption in the power supply can lead to a range of issues, from poor fuel economy and reduced power to complete engine failure. Regular checks and maintenance of the power source circuit are essential to prevent these problems.

Common Issues with the ECM Power Source Circuit

Battery Issues:

- Symptoms: The engine may not start, or there could be intermittent power loss while driving.

- Causes: Weak or dead battery, corroded terminals, or loose connections.

- Solutions: Check the battery’s voltage and charge it if necessary. Clean the terminals and ensure all connections are tight.

Blown Fuses:

- Symptoms: The ECM may not receive power, leading to engine performance issues or failure to start.

- Causes: Electrical surges or short circuits can cause fuses to blow.

- Solutions: Inspect the fuses related to the ECM and replace any that are blown. Identify and fix the underlying cause of the electrical surge.

Wiring Problems:

- Symptoms: Intermittent power loss, erratic engine behavior, or failure to start.

- Causes: Damaged or corroded wires, loose connections, or short circuits.

- Solutions: Inspect the wiring for any signs of damage or corrosion. Repair or replace damaged wires and secure any loose connections.

Connector Issues:

- Symptoms: Similar to wiring problems, with intermittent power loss or failure to start.

- Causes: Dirty or corroded connectors, loose connections.

- Solutions: Clean the connectors and ensure they are securely connected. Replace any damaged connectors.

Diagnostic Procedures for the ECM Power Source Circuit

Using a Multimeter:

- Voltage Check: Use a multimeter to check the voltage at various points in the ECM power source circuit. Ensure that the battery voltage is within the specified range (typically 12.6V to 14.7V).

- Continuity Test: Check the continuity of the wires and connectors in the ECM power source circuit to ensure there are no breaks or short circuits.

Step-by-Step Diagnostic Procedures:

- Battery Inspection:

- Visual Check: Inspect the battery for any signs of damage or corrosion on the terminals.

- Voltage Measurement: Measure the battery voltage using a multimeter. A fully charged battery should read around 12.6V. If the voltage is low, charge the battery or replace it if necessary.

- Fuse Inspection:

- Visual Check: Inspect the fuses related to the ECM power source circuit.

- Continuity Test: Use a multimeter to test the continuity of each fuse. Replace any fuses that do not have continuity.

- Wiring and Connector Inspection:

- Visual Check: Inspect the wiring and connectors for any signs of damage, corrosion, or loose connections.

- Continuity Test: Use a multimeter to check the continuity of the wires and connectors. Repair or replace any components that do not have continuity.

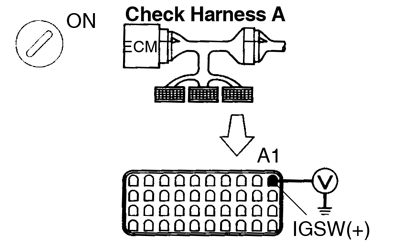

- ECM Power Source Circuit Test:

- Voltage Check: With the ignition on, measure the voltage at the ECM power connector. Ensure the voltage is within the specified range.

- Ground Check: Verify that the ECM has a good ground connection by measuring the resistance between the ECM ground terminal and the chassis ground. The resistance should be close to zero.

Preventive Maintenance Tips

Regular Battery Checks: Regularly check the battery’s condition, including its voltage and connections. Clean the terminals and ensure all connections are tight to prevent power supply issues.

Fuse Inspections: Inspect the fuses related to the ECM power source circuit during routine maintenance. Replace any blown fuses and investigate the cause of any electrical surges.

Wiring and Connector Maintenance: Regularly inspect the wiring and connectors for signs of damage or corrosion. Clean the connectors and secure any loose connections to ensure a reliable power supply to the ECM.

Conclusion

Maintaining the ECM power source circuit is essential for the optimal performance of the 2JZ-GTE engine. By understanding the circuit’s components, recognizing common issues, and following proper diagnostic and maintenance procedures, you can ensure that your engine runs smoothly.

Regularly check and maintain the ECM power source circuit to avoid performance issues. If you experience any symptoms of a faulty circuit, follow the diagnostic procedures outlined in this article. For more complex issues, seek professional help to ensure your engine remains in top condition.

Frequently Asked Questions (FAQ)

What is the ECM power source circuit?

The ECM power source circuit supplies the necessary electrical power to the Engine Control Module, which controls various engine functions.

How do I check the ECM power source circuit in my 2JZ-GTE engine?

Use a multimeter to check the voltage and continuity of the battery, fuses, wiring, and connectors in the ECM power source circuit.

Can I drive with a faulty ECM power source circuit?

It is not recommended to drive with a faulty ECM power source circuit, as it can lead to engine performance issues and potential failure.

What tools do I need to diagnose the ECM power source circuit?

A multimeter is essential for diagnosing the ECM power source circuit. It allows you to measure voltage and continuity to identify any issues.

How often should I check the ECM power source circuit?

Regularly check the ECM power source circuit during routine maintenance or if you notice any changes in engine performance or behavior.