The Legend of the 2JZ Engine

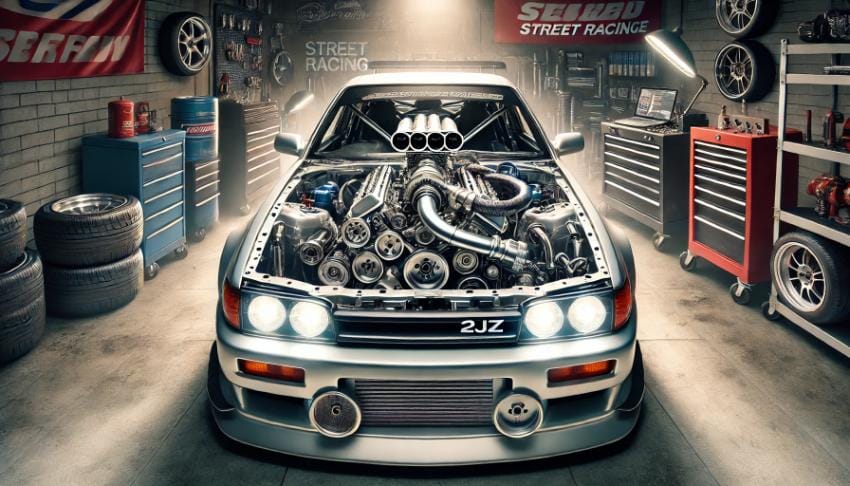

History and Popularity

The Toyota 2JZ engine debuted in the early 1990s as part of Toyota’s JZ-series of inline-six engines. Originally designed for the luxurious Toyota Aristo (known as the Lexus GS300 in some markets), the 2JZ rose to fame with its inclusion in the Toyota Supra MKIV. Its iron block construction, paired with its twin-turbo setup in the 2JZ-GTE variant, quickly set it apart as a high-performance powerhouse capable of enduring extreme stress and delivering exceptional power output.

In the realm of street racing, the 2JZ’s ability to achieve massive horsepower numbers—often exceeding 1,000hp with the right upgrades—cemented its place as a favorite among enthusiasts. Its reliability, tunability, and availability of aftermarket support make it a legend in motorsports and the go-to choice for anyone serious about speed.

Variants and Their Differences

The 2JZ engine family consists of two primary variants:

- 2JZ-GTE: The high-performance, twin-turbocharged variant. Equipped with forged internals, a stronger head gasket, and oil-cooled pistons, the GTE is built for extreme performance straight from the factory.

- 2JZ-GE: The naturally aspirated version. While less powerful than the GTE, it shares the same robust iron block and can be upgraded for forced induction, making it a budget-friendly alternative for builders.

| Key Specification | 2JZ-GTE | 2JZ-GE |

| Horsepower (Stock) | 280hp | 220hp |

| Compression Ratio | 8.5:1 | 10.0:1 |

| Induction Type | Twin Turbocharged | Naturally Aspirated |

| Application | Toyota Supra MKIV | Lexus GS300, others |

The GTE is the ideal starting point for high-power builds, while the GE is often chosen for cost-conscious projects.

Defining Your Build Goals

Before embarking on your 2JZ engine build, it’s crucial to establish clear goals to ensure your project meets your expectations. Whether you’re aiming for a high-horsepower street beast or a balanced daily driver with racing capabilities, setting a solid foundation will save you time, money, and effort in the long run.

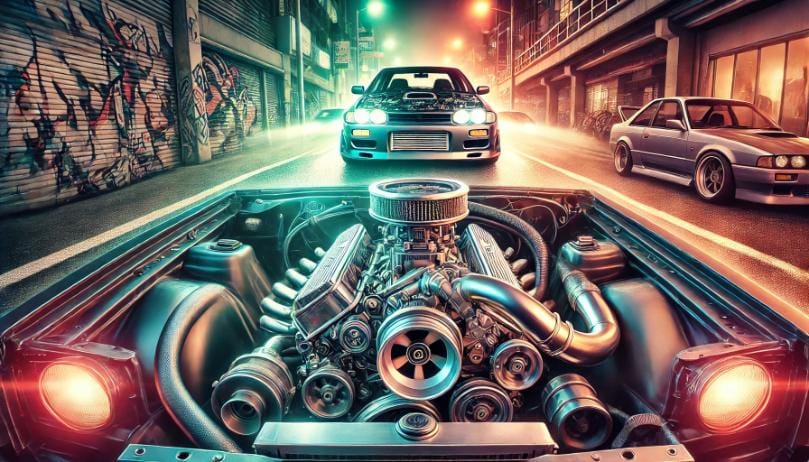

Street Racing Essentials

Street racing is about achieving the perfect balance between power, acceleration, handling, and reliability. Unlike track builds, street builds must handle everyday conditions like traffic, heat, and wear and tear while still delivering adrenaline-pumping performance.

Key Considerations for Street Racing Builds:

- Power Output: Aim for 500–800 horsepower for a reliable yet exhilarating street experience.

- Boost Response: Focus on minimizing turbo lag to ensure quick acceleration.

- Drivability: Prioritize a smooth power curve for better handling in various conditions.

- Durability: Select components that can withstand prolonged use without frequent maintenance.

Legal and Safety Considerations

A street racing build must adhere to local laws to remain street-legal while maintaining a focus on safety. Neglecting these considerations could lead to fines, vehicle impoundment, or worse.

Tips for Staying Street-Legal:

- Catalytic Converters: Ensure emissions compliance by installing a high-flow catalytic converter.

- Noise Levels: Use an exhaust system that meets local noise regulations.

- Safety Equipment: Include upgraded brakes, seatbelts, and even roll cages if necessary.

- Lighting and Signals: Maintain functional headlights, brake lights, and turn signals.

Budget Breakdown

Understanding the cost implications of your build is vital. Below is a general breakdown based on performance tiers:

| Performance Tier | Power Output | Approximate Cost | Key Components |

| Entry-Level Build | 400–500 hp | $5,000–$10,000 | Upgraded turbo, intercooler, basic ECU tuning |

| Mid-Tier Build | 500–700 hp | $10,000–$20,000 | Forged internals, standalone ECU, fuel system |

| High-End Build | 700–1,000+ hp | $20,000+ | Built block, large turbo, advanced tuning tools |

Proper budgeting ensures you prioritize essential upgrades while leaving room for unforeseen expenses.

Disassembly and Inspection

Before upgrading or assembling your 2JZ engine, thorough disassembly and inspection are vital. This ensures the engine block and components are in good condition and ready to handle the demands of street racing.

Step-by-Step Disassembly Guide

Disassembling your 2JZ engine properly requires attention to detail and the right tools. Below is a step-by-step process:

- Preparation:

- Drain all fluids, including oil and coolant.

- Label all hoses, wires, and components for easy reassembly.

- Organize tools and create a workspace.

- Remove External Components:

- Detach the intake manifold, exhaust manifold, and turbocharger (if applicable).

- Disconnect the alternator, power steering pump, and A/C compressor.

- Disassemble the Head:

- Remove the valve covers and camshafts.

- Take out the head bolts and carefully lift the cylinder head.

- Access the Bottom End:

- Remove the oil pan and oil pump.

- Detach the crankshaft pulley, timing belt, and associated components.

- Disassemble the Block:

- Remove pistons, connecting rods, and crankshaft.

- Extract any remaining bearings or seals.

Inspecting the Engine Components

After disassembly, inspect every part for wear, cracks, or damage. Use precision tools like micrometers and bore gauges for accurate measurements.

| Component | Inspection Criteria | Action if Damaged |

| Cylinder Block | Check for cracks, bore wear, or warping. | Resleeve or replace the block. |

| Pistons and Rods | Inspect for scoring, cracks, and deformation. | Upgrade to forged components if damaged. |

| Crankshaft | Look for scoring or bent sections. | Regrind or replace as needed. |

| Cylinder Head | Test for cracks and warped surfaces. | Resurface or replace. |

| Valvetrain Components | Check for wear on cams, lifters, and valves. | Replace with performance parts if needed. |

Cleaning and Preparing for Assembly

Once all components have been inspected:

- Clean all parts thoroughly to remove debris, oil, and carbon buildup.

- Hone the cylinders and deck the block if necessary.

- Replace all seals, gaskets, and bearings during reassembly to ensure reliability.

Tips for Success

- Use a detailed service manual for reference during disassembly.

- Take photos of each step to assist with reassembly.

- Invest in high-quality tools for precision work.

Internal Upgrades for High Performance

Building a 2JZ engine for street racing requires robust internal components to handle high horsepower and ensure reliability. Upgrading the internals lays the foundation for a powerful and durable engine.

Forged Pistons and Connecting Rods

Stock pistons and rods in the 2JZ-GTE can handle moderate power, but for higher horsepower builds (500+ HP), forged internals are essential.

- Benefits of Forged Pistons:

- Greater durability under high boost pressures.

- Improved heat resistance for prolonged engine life.

- Recommended Options:

- Pistons: JE Pistons, CP-Carrillo, or Wiseco.

- Rods: Manley, Eagle, or Brian Crower.

- Key Specifications to Look For:

- Compression ratio: 8.5:1 for high boost, 10.0:1 for better response.

Crankshaft and Bearings

The 2JZ’s factory crankshaft is incredibly robust and can support up to 1,000 HP with proper balancing. However, upgrading to a billet crankshaft or adding a stroker kit can unlock even more performance.

- Billet Crankshafts: Ideal for extreme builds exceeding 1,000 HP.

- Bearings: Use high-performance bearings from brands like ACL or King Racing for better lubrication and load tolerance.

Valvetrain Upgrades

An upgraded valvetrain ensures the engine can handle higher RPMs without valve float or failure.

- Cams: High-lift camshafts increase airflow and performance. Popular options include Brian Crower and HKS.

- Valves and Springs:

- Titanium valves for reduced weight.

- Dual valve springs for stability at high RPM.

- Retainers and Locks: Upgrade to titanium retainers for improved durability.

Head Gasket and ARP Studs

A high-performance head gasket and ARP head studs are crucial for sealing the combustion chamber under high boost.

- Head Gaskets:

- Multi-layer steel (MLS) gaskets are ideal for durability.

- Brands like Cometic and HKS offer reliable options.

- ARP Studs:

- Prevent head lift during high-pressure operation.

Stroker Kits

A stroker kit increases the engine’s displacement, resulting in better low-end torque and overall power.

- Benefits:

- Enhanced power delivery across the RPM range.

- Increased throttle response and acceleration.

- Popular Options:

- Brian Crower 3.4L stroker kit (crankshaft, rods, and pistons).

Budget Breakdown for Internal Upgrades

| Component | Estimated Cost | Purpose |

| Forged Pistons | $800–$1,500 | Handle higher boost and temperatures. |

| Connecting Rods | $700–$1,200 | Increased strength and durability. |

| Valvetrain Components | $1,200–$2,000 | Stability at high RPMs. |

| Head Gasket and Studs | $500–$1,000 | Ensure proper sealing under high pressure. |

| Stroker Kit | $3,000–$5,000 | Increase displacement and torque. |

Turbocharging: Single vs. Twin Turbo Setups

Turbocharging is one of the most impactful upgrades for a 2JZ engine, providing substantial power gains and performance versatility. Choosing between a single or twin-turbo setup depends on your goals for power, response, and usability.

Single vs. Twin Turbo: A Comparison

| Factor | Single Turbo | Twin Turbo |

| Power Output | Can produce extreme horsepower (700–1,000+). | Ideal for moderate power goals (500–700). |

| Turbo Lag | More noticeable lag at low RPM. | Reduced lag due to smaller turbo size. |

| Complexity | Simpler installation and fewer components. | More complex setup with extra piping. |

| Cost | Generally more cost-effective. | Slightly more expensive overall. |

- Best for Single Turbo: High-horsepower builds prioritizing top-end performance.

- Best for Twin Turbo: Builds aiming for responsiveness and balanced power delivery.

Choosing the Right Turbo

Selecting the correct turbocharger is critical to achieving your desired performance. Factors to consider include spool time, airflow capacity, and intended use.

- Popular Single Turbo Options:

- Garrett GTX3582R: Excellent for street applications with ~800 HP capacity.

- Precision Turbo 6466: Capable of supporting 700–1,000 HP.

- Popular Twin Turbo Options:

- HKS GTIII-RS: Compact design, great for street use.

- BorgWarner EFR Series: Lightweight and responsive.

Turbo Sizing Considerations:

- Match the compressor size (measured in mm) to your horsepower goals.

- Larger turbos offer more power but spool slower.

Supporting Modifications for Turbocharging

To ensure reliability and efficiency, your turbo setup requires the following supporting upgrades:

- Manifolds:

- Single Turbo: Use a tubular manifold for better exhaust flow.

- Twin Turbo: Ensure compatibility with the factory manifold or upgrade to high-flow designs.

- Intercoolers:

- Front-mounted intercoolers are essential to cool compressed air.

- Look for core sizes that fit your power goals (e.g., 4-inch cores for high HP builds).

- Wastegates:

- External wastegates provide better boost control.

- Recommended brands: Tial, Turbosmart.

- Blow-Off Valves:

- Protect your turbo from compressor surge during throttle lifts.

- Tial and HKS are popular choices.

Boost Control and Management

Proper boost management ensures the engine runs efficiently and safely.

- Boost Controllers:

- Electronic controllers like the Greddy Profec allow fine-tuning of boost levels.

- Manual controllers are cost-effective but less precise.

- Boost Gauges:

- Essential for monitoring boost pressure in real-time.

- Digital gauges provide higher accuracy.

Practical Tips for Turbo Setup

- Use high-quality oil lines and fittings to ensure reliable lubrication.

- Heat-wrap exhaust manifolds and downpipes to improve efficiency and protect nearby components.

- Always tune your engine after installing a turbo to prevent detonation and maximize power.

Budget Breakdown for Turbocharging

| Component | Estimated Cost | Purpose |

| Single Turbo (GTX3582R) | $2,000–$2,500 | High power with moderate spool. |

| Twin Turbos (HKS GTIII-RS) | $3,000–$4,000 | Balanced power with minimal lag. |

| Intercooler System | $500–$1,000 | Reduces intake air temperature. |

| Manifold (Single/Twin) | $600–$1,500 | Improves exhaust flow to the turbo(s). |

| Wastegates & BOVs | $400–$800 | Boost control and surge protection. |

| Boost Controller | $300–$700 | Allows boost level adjustments. |

Fuel System Enhancements

Upgrading the fuel system is critical when building a high-performance 2JZ engine. Proper fuel delivery ensures the engine receives enough fuel under boost, preventing lean conditions that could cause catastrophic damage.

Fuel Injectors and Fuel Pump Upgrades

The stock 2JZ fuel system is adequate for mild performance, but for street racing builds aiming for 500+ horsepower, upgraded injectors and pumps are a must.

- Fuel Injectors:

- Choose injectors based on horsepower goals:

- 550cc for up to 450 HP.

- 1,000cc for 600–800 HP.

- 1,500cc+ for builds exceeding 1,000 HP.

- Recommended Brands: Injector Dynamics, Bosch, DeatschWerks.

- Choose injectors based on horsepower goals:

- Fuel Pump:

- High-flow fuel pumps provide the necessary fuel volume for performance builds.

- Popular Options:

- Walbro 450LPH: Budget-friendly and supports up to 750 HP.

- AEM 340LPH: Great for moderate builds.

- Radium Engineering: High-performance dual or triple pump setups.

Fuel Pressure Regulation

A reliable fuel pressure regulator ensures consistent fuel delivery under varying load conditions. Adjustable regulators allow fine-tuning for optimal air-fuel ratios.

- Recommended Products:

- Aeromotive Adjustable Fuel Pressure Regulators.

- DeatschWerks FPR Kit.

Fuel Types for Maximum Performance

The type of fuel you choose impacts both performance and safety.

- E85 Ethanol:

- Benefits:

- High knock resistance allows for aggressive tuning.

- Cools the intake charge, increasing power.

- Drawbacks:

- Requires a flex-fuel sensor and compatible fuel lines.

- More frequent refueling due to lower energy density.

- Benefits:

- Race Fuel:

- Benefits:

- Consistent quality and high octane ratings (100+).

- Best for occasional racing events due to cost.

- Benefits:

- Pump Gas:

- Ideal for moderate builds or daily driving.

- Limit boost levels to prevent knock.

Fuel Lines, Rails, and Filters

Upgraded fuel lines and rails are necessary to support increased flow and pressure.

- Fuel Rails:

- High-flow rails prevent fuel starvation to the injectors.

- Brands: Radium Engineering, AEM, and Injector Dynamics.

- Fuel Filters:

- Inline filters protect the injectors and fuel pump from debris.

- Use stainless steel or high-flow paper filters.

- Fuel Lines:

- PTFE-lined braided hoses resist corrosion from ethanol-based fuels.

Practical Tips for Upgrading the Fuel System

- Always match injector size with your target horsepower and ECU tuning.

- Consider running a return-style fuel system for better pressure control.

- Ensure proper tuning after fuel system upgrades to avoid running rich or lean.

Budget Breakdown for Fuel System Upgrades

| Component | Estimated Cost | Purpose |

| Fuel Injectors | $500–$1,000 | Deliver sufficient fuel for high power. |

| High-Flow Fuel Pump | $300–$800 | Ensure consistent fuel supply. |

| Fuel Pressure Regulator | $200–$500 | Maintain stable fuel pressure. |

| Fuel Lines and Rails | $400–$900 | Handle increased fuel flow and pressure. |

| Fuel Filter | $100–$300 | Prevent contamination of fuel components. |

Engine Management and Tuning

Proper engine management and tuning are essential to unlocking the full potential of your 2JZ engine. A reliable Engine Control Unit (ECU) and precise tuning will ensure your build achieves optimal power, reliability, and efficiency.

Choosing the Right ECU

A standalone ECU provides the flexibility needed for custom tuning and advanced control of your 2JZ engine’s performance.

- Popular Standalone ECU Options:

- AEM Infinity: Offers excellent tuning control, data logging, and plug-and-play compatibility for 2JZ builds.

- Haltech Elite 2500: Known for its user-friendly interface and comprehensive features, including wideband O2 integration.

- ECUMaster EMU Black: A cost-effective option for moderate builds with robust tuning capabilities.

- Key Features to Consider:

- Multiple fuel and ignition maps.

- Boost-by-gear control for improved traction.

- Data logging and real-time monitoring.

Tuning for Optimal Performance

Tuning adjusts your engine’s air-fuel ratio, ignition timing, and boost levels to maximize power while maintaining reliability. Professional dyno tuning is highly recommended to achieve precise results.

- Key Parameters for Tuning:

- Air-Fuel Ratio (AFR):

- Target ~12:1 for boosted applications under load.

- Maintain leaner ratios (~14.7:1) during cruising for fuel economy.

- Ignition Timing:

- Advance timing for power but avoid knock or detonation.

- Boost Control:

- Map boost levels to different gears for better traction.

- Air-Fuel Ratio (AFR):

- Tools for Tuning:

- Wideband O2 sensors for accurate AFR readings.

- Knock sensors to detect pre-detonation.

Advanced Features for Street Racing

Standalone ECUs come with advanced features that are particularly useful for street racing applications:

- Traction Control:

- Limits wheel spin during aggressive launches or in wet conditions.

- Launch Control:

- Allows you to build boost while stationary for quick launches.

- Flex-Fuel Capability:

- Adjusts fuel maps automatically based on ethanol content in your fuel.

Dyno Tuning vs. Street Tuning

Both methods have their advantages, but using a combination of the two is ideal for a street racing build.

- Dyno Tuning:

- Provides a controlled environment for precise adjustments.

- Allows full power runs to test performance and reliability.

- Street Tuning:

- Ensures drivability under real-world conditions.

- Fine-tunes throttle response, boost delivery, and fuel economy.

Ongoing Monitoring and Maintenance

After tuning, regular monitoring ensures your engine remains healthy and performs optimally.

- Essential Gauges:

- Boost gauge to track turbo performance.

- Wideband AFR gauge for monitoring fuel mixture.

- Oil pressure and temperature gauges for critical engine health.

- Software Updates:

- Periodically update your ECU’s firmware to access new features and improvements.

Budget Breakdown for Engine Management

| Component | Estimated Cost | Purpose |

| Standalone ECU | $1,000–$2,500 | Advanced control over engine performance. |

| Dyno Tuning | $500–$1,000 per session | Precision adjustments for power and safety. |

| Wideband O2 Sensor | $200–$400 | Accurate AFR monitoring. |

| Boost Controller | $300–$700 | Fine-tune boost levels. |

| Monitoring Gauges | $400–$800 | Real-time data on critical parameters. |

Cooling and Lubrication Upgrades

Upgrading the cooling and lubrication systems is essential for maintaining the reliability and longevity of your 2JZ engine, especially under the extreme demands of street racing. Proper cooling prevents overheating, while a robust lubrication system ensures all engine components function smoothly under high stress.

Cooling System Enhancements

A high-performance cooling system is critical to dissipate the heat generated by a turbocharged 2JZ engine.

- Radiators:

- Use an aluminum, high-capacity radiator for improved heat dissipation.

- Popular Options: Mishimoto, KoyoRad, CSF.

- Intercoolers:

- A larger, front-mounted intercooler (FMIC) reduces the intake air temperature, increasing engine efficiency.

- Core size recommendations:

- 3-inch core for moderate builds (up to 500 HP).

- 4-inch core for high-performance builds (500+ HP).

- Electric Fans:

- High-flow electric fans improve airflow, especially in stop-and-go traffic.

- Dual-fan setups offer better cooling for larger radiators.

- Thermostats and Water Pumps:

- Upgrade to a low-temperature thermostat to maintain optimal engine temperatures.

- Consider an upgraded water pump for better coolant circulation.

Lubrication System Upgrades

Efficient oil circulation prevents overheating and reduces wear on critical engine components during prolonged street racing.

- Oil Coolers:

- Install an external oil cooler to reduce oil temperatures during heavy usage.

- Recommended Brands: Setrab, Greddy.

- High-Capacity Oil Pans:

- Increased oil capacity improves lubrication and helps maintain oil pressure under high-G forces.

- Baffled oil pans prevent oil starvation during hard cornering or launches.

- Catch Cans:

- Capture blow-by gases and prevent oil vapors from entering the intake system.

- Popular Choices: Mishimoto, Radium Engineering.

- Oil Pumps:

- Upgrade to a high-volume oil pump to ensure consistent oil flow at high RPMs.

Heat Management Solutions

Managing heat effectively is crucial for sustaining performance and protecting components.

- Exhaust Wraps and Turbo Blankets:

- Wrap headers and install turbo blankets to retain heat within the exhaust system, improving efficiency.

- Prevents heat transfer to nearby engine components.

- Coolant Additives:

- Products like Red Line Water Wetter reduce coolant temperatures for added efficiency.

Practical Tips for Cooling and Lubrication

- Regularly inspect hoses and seals for leaks or wear.

- Use high-quality, synthetic oil with the appropriate viscosity for your build.

- Flush and replace coolant and oil at recommended intervals to maintain performance.

Budget Breakdown for Cooling and Lubrication Upgrades

| Component | Estimated Cost | Purpose |

| High-Capacity Radiator | $300–$800 | Improved engine cooling. |

| Intercooler System | $500–$1,500 | Reduces intake air temperature. |

| Oil Cooler | $400–$1,000 | Keeps oil temperatures within safe limits. |

| Baffled Oil Pan | $300–$600 | Prevents oil starvation under high G-forces. |

| Turbo Blankets & Wraps | $100–$300 | Manages heat effectively. |

Exhaust System Optimization

The exhaust system of your 2JZ engine plays a critical role in enhancing performance, managing sound levels, and maintaining emissions compliance for street use. A properly designed exhaust system optimizes airflow, reduces backpressure, and supports the turbocharging setup.

Key Components of a High-Performance Exhaust System

- Downpipe:

- Connects the turbocharger to the exhaust system.

- Larger diameters (e.g., 3 inches or more) reduce backpressure and improve turbo efficiency.

- Materials: Stainless steel or titanium for durability and heat resistance.

- Cat-Back Exhaust:

- The section from the catalytic converter to the exhaust tip.

- Upgraded cat-back systems enhance exhaust flow and deliver a more aggressive sound.

- Popular Brands: HKS, Greddy, Apexi.

- Catalytic Converter:

- High-flow catalytic converters maintain emissions compliance while allowing improved airflow.

- Options include metallic core designs for durability under high temperatures.

- Muffler:

- Reduces noise levels while maintaining a sporty tone.

- Straight-through designs provide the best flow and minimal restrictions.

Material Options

- Stainless Steel:

- Corrosion-resistant and durable.

- Ideal for street use due to its longevity.

- Titanium:

- Lightweight and strong but more expensive.

- Perfect for reducing overall vehicle weight in high-performance builds.

Balancing Sound and Performance

Street builds require a balance between performance and legal sound levels.

- Resonators:

- Help reduce drone and harsh frequencies without sacrificing flow.

- Ideal for daily-driven street cars.

- Sound Tuning Tips:

- Use adjustable valves for controlling exhaust volume.

- Opt for dual exhaust tips for better sound distribution.

Headers for Naturally Aspirated Builds

If building a 2JZ-GE or a low-boost GTE:

- Upgrade to long-tube headers to improve exhaust scavenging.

- Ceramic-coated headers help retain heat and improve flow.

Practical Installation Tips

- Ensure proper fitment with your turbo setup to avoid exhaust leaks.

- Use V-band clamps for easy installation and removal.

- Regularly inspect for rust or cracks, especially in high-stress areas like the downpipe.

Budget Breakdown for Exhaust System Upgrades

| Component | Estimated Cost | Purpose |

| Downpipe | $300–$800 | Reduces backpressure and improves turbo spool. |

| Cat-Back Exhaust System | $600–$1,500 | Enhances flow and sound. |

| High-Flow Catalytic Converter | $400–$1,000 | Maintains emissions compliance with minimal flow restriction. |

| Resonators | $150–$400 | Reduces unwanted noise without sacrificing performance. |

| Muffler | $200–$500 | Balances sound and performance. |

Final Thoughts on Exhaust Systems

An optimized exhaust system is the key to unlocking additional power and achieving the signature sound of a high-performance 2JZ. Balancing flow, sound, and emissions compliance ensures your build is both powerful and street-ready.

Assembling Your 2JZ

With all components upgraded and prepared, it’s time to assemble your 2JZ engine. This step requires meticulous attention to detail, as proper assembly ensures the reliability and performance of your build. Below is a step-by-step guide to assembling your 2JZ engine for street racing.

Pre-Assembly Preparation

- Work Area:

- Set up a clean and organized workspace to prevent contamination.

- Use lint-free cloths and ensure all tools are within reach.

- Parts Checklist:

- Verify that all necessary components, seals, and gaskets are on hand.

- Confirm compatibility between upgraded parts (e.g., pistons, rods, bearings).

- Lubrication:

- Use high-quality assembly lube for bearings, camshafts, and valvetrain components.

- Coat piston rings and cylinder walls with engine oil.

Step-by-Step Assembly Process

- Block Preparation:

- Ensure the cylinder block is clean and free of debris.

- Install new freeze plugs and oil gallery plugs.

- Install Crankshaft:

- Lay the crankshaft into the main bearings and check clearances using plastigauge.

- Torque the main caps to the manufacturer’s specifications in a cross-pattern.

- Piston and Rod Assembly:

- Attach forged pistons to the connecting rods using wrist pins.

- Compress piston rings and carefully insert the piston-rod assemblies into the cylinders.

- Torque rod bolts to spec.

- Cylinder Head Installation:

- Place the multi-layer steel (MLS) head gasket onto the block.

- Position the cylinder head and secure it using ARP head studs.

- Torque the studs in sequence, following the manufacturer’s guidelines.

- Camshaft and Valvetrain:

- Lubricate and install the camshafts into the cylinder head.

- Align timing marks and install the timing belt or chain.

- Verify that valve lash is within spec.

- Oil Pan and Pump:

- Install the oil pump and pickup tube.

- Attach the oil pan using a high-temperature sealant on the mating surfaces.

- Accessory Installation:

- Reattach the alternator, power steering pump, and other accessories.

- Install the intake and exhaust manifolds.

- Turbo and Plumbing:

- Mount the turbocharger(s) and connect all oil, water, and boost lines.

- Verify that all clamps and connections are secure.

- Final Steps:

- Install spark plugs and ignition coils.

- Attach the fuel rail, injectors, and sensors.

- Double-check all bolts, connections, and fluid levels.

First Startup Procedure

- Priming the Oil System:

- Disable the ignition and fuel systems, then crank the engine to build oil pressure.

- Initial Idle:

- Start the engine and allow it to idle while monitoring oil pressure and coolant temperature.

- Break-In Period:

- Vary RPMs during the first 500 miles to seat the piston rings properly.

- Avoid full-throttle runs or high RPMs during this period.

Testing and Troubleshooting

After assembly, perform the following checks:

- Compression Test: Ensure even compression across all cylinders.

- Leak Test: Check for coolant or oil leaks at all seals and connections.

- Dyno Testing: Fine-tune the engine for optimal performance under load.

Budget Breakdown for Assembly

| Component | Estimated Cost | Purpose |

| Assembly Tools (Torque Wrenches, Plastigauge, etc.) | $200–$500 | Accurate and precise assembly. |

| Assembly Lube and Sealants | $50–$100 | Smooth operation and proper sealing. |

| MLS Head Gasket | $200–$400 | High-pressure sealing for the cylinder head. |

| ARP Head Studs | $200–$500 | Prevent head lift under high boost. |

Tips for Success

- Follow torque specifications and assembly procedures precisely.

- Keep a detailed log of all clearances and measurements for future reference.

- Take your time—rushing can lead to costly mistakes.

Testing and Troubleshooting

After assembling your 2JZ engine, thorough testing and troubleshooting are essential to ensure everything functions as expected. This phase is crucial for identifying potential issues and optimizing the engine for peak performance and reliability.

Initial Engine Tests

Before putting your engine to use, perform these preliminary checks:

- Compression Test:

- Measure cylinder compression to ensure uniform pressure across all cylinders.

- Ideal compression for a 2JZ-GTE: ~170-200 PSI (depending on modifications).

- Leak-Down Test:

- Detect leaks in the combustion chamber, valves, or head gasket.

- Healthy engines typically show less than 10% leakage.

- Oil Pressure Test:

- Monitor oil pressure at idle and under load.

- Verify it meets the 2JZ specifications (20-30 PSI at idle, 50-70 PSI under load).

- Coolant System Pressure Test:

- Ensure there are no leaks in the cooling system.

- Test pressure should match the radiator cap rating.

First Dyno Test

Dyno testing is a critical step to safely push your engine under controlled conditions:

- Goals:

- Verify that the air-fuel ratio (AFR) remains safe under boost.

- Optimize ignition timing and boost levels for maximum power.

- Ensure engine temperatures stay within safe limits.

- Key Metrics to Monitor:

- Peak horsepower and torque outputs.

- Boost pressure and turbo spool time.

- Fuel injector duty cycle and fuel pump performance.

Common Issues and Their Solutions

Here are some typical problems that may arise during testing and how to address them:

| Issue | Cause | Solution |

| Overheating | Inadequate cooling or air pockets in system | Bleed cooling system, upgrade radiator. |

| Low Oil Pressure | Worn bearings or oil pump issues | Inspect bearings, replace oil pump. |

| Misfires | Faulty spark plugs, ignition coils, or tuning | Replace components, adjust fuel/ignition. |

| Boost Leaks | Loose couplers or damaged intercooler piping | Pressure test and tighten connections. |

| Detonation or Knock | Poor fuel quality or aggressive timing | Retune ignition and switch to higher-octane fuel. |

Fine-Tuning for Street Racing

Once initial testing is complete, refine the engine’s performance for real-world conditions:

- Boost-by-Gear:

- Adjust boost levels based on gear to improve traction during launches.

- Traction Control:

- Use ECU settings to limit wheelspin under hard acceleration.

- Street Drivability:

- Smooth out throttle response and idle for everyday usability.

Post-Build Maintenance Checklist

To maintain peak performance and reliability:

- Oil Changes:

- Perform the first oil change after 500 miles, then follow a regular schedule (e.g., every 3,000 miles or sooner under heavy use).

- Fluid Checks:

- Regularly inspect coolant, oil, and brake fluid levels.

- Fastener Inspection:

- Retorque critical bolts, especially on the cylinder head and manifolds, after the break-in period.

Budget Breakdown for Testing and Troubleshooting

| Component | Estimated Cost | Purpose |

| Compression Tester | $50–$100 | Ensures cylinder compression consistency. |

| Leak-Down Tester | $100–$300 | Identifies internal leaks. |

| Dyno Tuning Session | $500–$1,000 per session | Optimizes engine performance. |

| Data Logging Software | $100–$300 | Monitors engine parameters during testing. |

Tips for Success

- Always test in a controlled environment to avoid unnecessary risks.

- Consult a professional tuner or mechanic if you encounter complex issues.

- Log all testing data to track performance trends and adjustments.

Case Studies and Conclusion

Examining real-world 2JZ builds provides valuable insights into the practical application of the techniques and upgrades outlined in this guide. Below are two standout case studies, followed by a summary to conclude your 2JZ street racing build journey.

Case Studies

Case Study 1: Jared’s 7-Second Street Supra

- Overview: Jared’s Supra, equipped with a fully built 2JZ-GTE, achieves a 7-second quarter-mile while remaining street legal.

- Key Modifications:

- Turbo: Precision 8685 Gen2 single turbo.

- Internals: Forged pistons, rods, and billet crankshaft.

- Fuel System: E85 with dual Walbro 525 fuel pumps.

- Engine Management: Haltech Elite 2500 standalone ECU.

- Lessons Learned:

- Advanced tuning, combined with high-quality components, ensures both performance and reliability.

- Proper cooling and heat management are critical for sustained performance under intense use.

Case Study 2: Papadakis Racing’s Short-Block Build

- Overview: Stephan Papadakis demonstrates the process of building a high-horsepower 2JZ short-block for competitive racing.

- Key Modifications:

- Short-Block: Precision machining with forged internals.

- Valvetrain: Dual valve springs and titanium retainers.

- Stroker Kit: Brian Crower 3.4L for enhanced torque.

- Lessons Learned:

- Precision and attention to detail during assembly significantly increase engine longevity.

- Matching components to power goals avoids unnecessary expenses.

Conclusion

Building a 2JZ engine for street racing is both an art and a science. By following the steps in this guide, you can create a reliable, high-performance engine that excels in street conditions. From selecting the right turbocharger to perfecting the tune, every choice you make contributes to your engine’s performance and longevity.

Key Takeaways:

- Preparation: Start with a clear plan, budget, and understanding of your power goals.

- Quality Components: Invest in high-quality parts that match your build requirements.

- Professional Assistance: Leverage professional tuners and machinists for precision work.

- Ongoing Maintenance: Regular inspections and maintenance are essential for sustained performance.

Are you ready to dominate the streets with your custom-built 2JZ? Share your build journey, join discussions, and explore more resources on our blog to continue enhancing your 2JZ expertise. Together, we’ll keep pushing the limits of performance!

Frequently Asked Questions (FAQ)

What is the ideal power range for a street racing 2JZ build?

The ideal power range for a street racing 2JZ build is between 500–800 horsepower. This range balances reliability, drivability, and performance for street use. Beyond 800 HP, additional upgrades to the drivetrain, cooling, and fuel system are often required to maintain usability in daily driving conditions.

Can I use the 2JZ-GE for a turbocharged build, or should I start with a 2JZ-GTE?

The 2JZ-GE can be turbocharged and is a cost-effective option for budget builds. However, the 2JZ-GTE is the better choice for high-power applications due to its stronger internals (e.g., forged pistons) and factory turbo-ready design. For builds aiming above 600 HP, the 2JZ-GTE is more reliable out of the box.

What is the best turbo for a street racing 2JZ?

The best turbo depends on your goals:

- Single Turbo: The Garrett GTX3582R is a popular choice for street builds, offering quick spool and support for up to 800 HP.

- Twin Turbo: The HKS GTIII-RS provides a balance between responsiveness and power for builds in the 500–700 HP range. Always match your turbo choice to your desired power output and driving style.

How often should I perform maintenance on a high-performance 2JZ?

High-performance 2JZ engines require more frequent maintenance:

- Oil Changes: Every 2,500–3,000 miles or after every race event.

- Spark Plugs: Inspect and replace every 5,000–10,000 miles, depending on heat range and use.

- Coolant: Flush and replace annually or sooner if the engine runs excessively hot.

- Timing Belt: Inspect every 15,000 miles and replace every 60,000 miles.

Can I run E85 on a street-legal 2JZ build?

Yes, E85 is an excellent fuel for street-legal 2JZ builds due to its high knock resistance and cooling properties. However:

- Your fuel system must be E85-compatible (e.g., upgraded injectors, fuel lines, and fuel pump).

- A flex-fuel sensor is recommended to switch seamlessly between E85 and pump gas.

- Note that E85 requires more frequent refueling due to lower energy density.