Inspecting ECM (Engine Control Module) connectors and terminals is a vital aspect of vehicle maintenance, particularly for high-performance engines like the 2JZ-GTE. ECM connectors and terminals are crucial for ensuring proper communication between the ECM and various engine components. For 2JZ-GTE engine enthusiasts, regular inspection of these connectors and terminals helps maintain engine efficiency and prevents potential issues that could impact performance.

In this guide, we will explore the importance of inspecting ECM connectors and terminals, outline common issues, and provide detailed diagnostic procedures. By following these steps, you can ensure your engine’s electrical connections remain reliable and effective.

Understanding ECM Connectors and Terminals

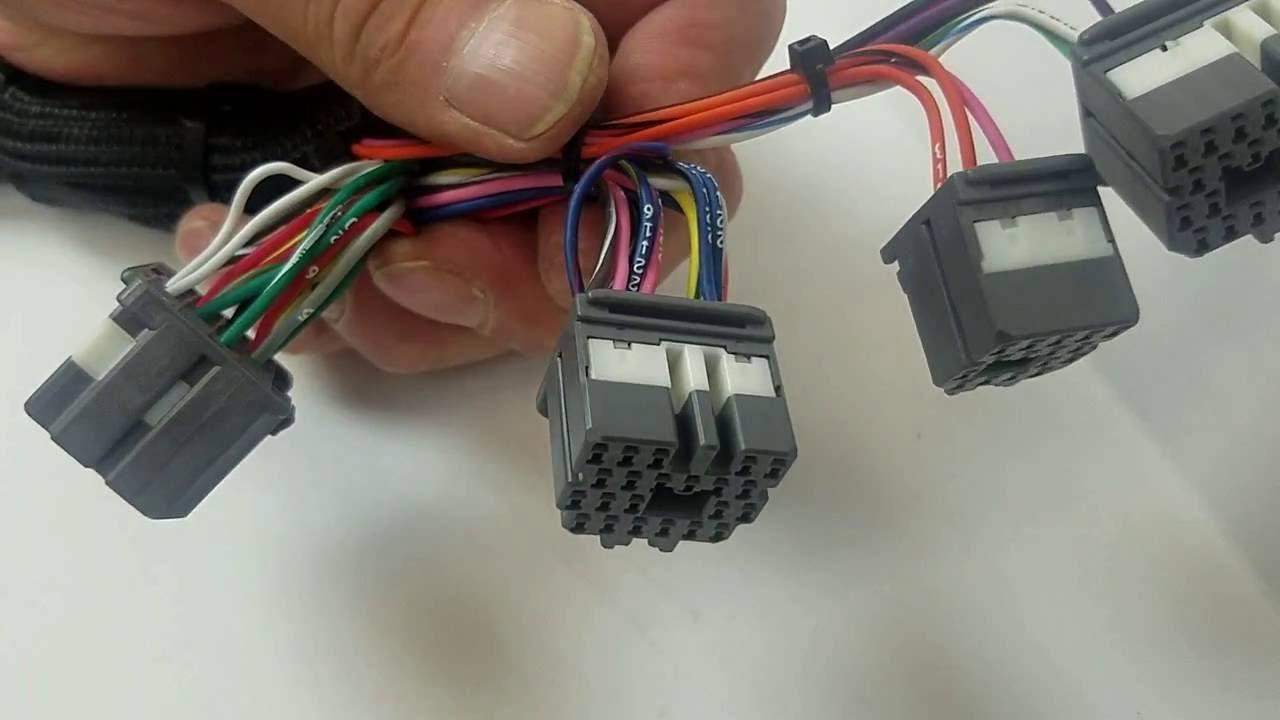

ECM connectors and terminals are integral parts of the engine’s electrical system, enabling communication between the ECM and various sensors and actuators. These components must be in good condition to ensure accurate data transmission and optimal engine performance.

Types of ECM Connectors and Terminals in the 2JZ-GTE Engine:

- Power Supply Connectors: Provide the necessary power to the ECM.

- Sensor Connectors: Connect various sensors to the ECM for data transmission.

- Actuator Connectors: Connect actuators, such as fuel injectors and ignition coils, to the ECM.

Proper inspection of these connectors and terminals helps in diagnosing issues such as communication errors, sensor malfunctions, and overall engine performance problems.

Common Issues with ECM Connectors and Terminals

Several issues can affect ECM connectors and terminals, leading to various engine performance problems. Identifying these issues early is crucial for maintaining the engine’s reliability.

Common Issues:

- Corrosion: Corrosion on connectors and terminals can impede electrical conductivity, leading to poor performance or communication failures.

- Loose Connections: Loose or poorly connected terminals can result in intermittent electrical connections, causing erratic engine behavior.

- Damaged Wiring: Frayed or damaged wires connected to the ECM can disrupt the flow of data and power.

- Debris and Contaminants: Dirt, oil, and other contaminants can accumulate on connectors and terminals, affecting their performance.

Diagnostic Trouble Codes (DTCs) Related to ECM Connectors and Terminals:

- P0600: Serial Communication Link Malfunction

- P0606: ECM/PCM Processor Fault

- P0641: Sensor Reference Voltage ‘A’ Circuit/Open

Understanding these common issues and related DTCs can help you pinpoint the source of ECM connector and terminal problems.

Diagnostic Procedures for ECM Connectors and Terminals

Performing thorough inspections of ECM connectors and terminals involves several diagnostic steps. Here is a step-by-step guide to help you diagnose these issues effectively:

Tools Required:

- Multimeter: For measuring voltage, resistance, and continuity.

- Inspection Light: To visually inspect hard-to-see areas.

- Contact Cleaner: To clean connectors and terminals.

- Wire Strippers and Crimpers: For repairing or replacing damaged wiring.

Step-by-Step Guide:

- Preparation:

- Ensure the engine is off and the key is removed from the ignition.

- Disconnect the battery to prevent any electrical shorts.

- Visual Inspection:

- Inspect all ECM connectors and terminals for signs of corrosion, damage, or loose connections.

- Use an inspection light to check difficult areas and ensure all connectors are securely attached.

- Cleaning:

- Use contact cleaner to remove any dirt, oil, or contaminants from the connectors and terminals.

- Allow the cleaner to dry completely before proceeding with further tests.

- Continuity Testing:

- Set the multimeter to the continuity mode.

- Test each wire connected to the ECM for continuity by placing the leads on both ends of the wire.

- Voltage Testing:

- Reconnect the battery and turn the ignition to the “ON” position.

- Measure the voltage at various ECM terminals and compare it to the specifications in the service manual.

- Resistance Measurement:

- Disconnect the ECM connectors you are testing.

- Measure the resistance and compare it to the specifications in the service manual.

- High resistance may indicate a faulty connection or damaged wiring.

Interpreting Results:

- Normal Readings: Indicate the connectors and terminals are functioning correctly.

- Abnormal Readings: Suggest an issue such as a poor connection, corrosion, or damaged wiring.

By following these steps, you can accurately diagnose ECM connector and terminal issues, ensuring your engine performs optimally.

Best Practices for ECM Connector and Terminal Inspection

To maintain the health of your engine’s electrical connections, follow these best practices:

Common Solutions:

- Repair Damaged Wiring: Replace or repair any frayed or damaged wires connected to the ECM.

- Clean Connectors and Terminals: Regularly clean connectors and terminals to remove contaminants and prevent corrosion.

- Secure Connections: Ensure all connectors are securely attached and properly insulated.

Preventive Maintenance Tips:

- Regular Inspections: Perform visual inspections regularly to catch any issues early.

- Use Quality Parts: Always use high-quality connectors and wiring to prevent future problems.

- Keep Documentation: Maintain a record of all inspections and repairs for future reference.

By adhering to these best practices, you can prevent many common electrical issues and ensure the longevity and performance of your 2JZ-GTE engine.

Conclusion

In summary, regular inspection of ECM connectors and terminals is crucial for diagnosing and resolving electrical issues in your 2JZ-GTE engine. By understanding the types of connectors and terminals, common issues, and using the right diagnostic tools, you can ensure your engine operates efficiently and reliably.

If you suspect any issues with your ECM connectors or terminals, don’t wait. Perform a detailed inspection using the steps outlined in this guide and refer to your service manual for specific diagnostic procedures. Regular inspections and timely repairs will help maintain the performance and longevity of your 2JZ-GTE engine.

Frequently Asked Questions (FAQ)

What are the common symptoms of ECM connector and terminal issues?

Common symptoms include intermittent electrical connections, engine misfires, poor performance, and diagnostic trouble codes (DTCs) related to communication errors.

How can I tell if my ECM connector or terminal problem is serious?

Serious ECM connector or terminal problems often trigger DTCs and can cause significant performance issues or prevent the engine from starting.

What tools do I need to inspect ECM connectors and terminals?

You will need a multimeter, an inspection light, contact cleaner, and wire strippers and crimpers.

Can I drive with faulty ECM connectors or terminals?

It is not recommended to drive with faulty ECM connectors or terminals, as it can lead to further damage and potentially leave you stranded.

How often should I check my ECM connectors and terminals for issues?

Regular inspections should be performed during routine maintenance, such as every oil change or every 10,000 miles.