The 2JZ engine is more than just a piece of machinery; it’s a cultural icon in the world of automotive performance. Known for its legendary durability and near-limitless tuning potential, the 2JZ has cemented its place as one of the most sought-after engines for high-performance builds. Whether you’re a drag racer, a drifter, or someone looking to build the ultimate street machine, the 2JZ is often the engine of choice.

But achieving greatness comes at a cost. Building a high-performance 2JZ engine requires careful planning, not just for performance goals but also for budgeting. From sourcing quality parts to ensuring professional assembly, the process is both an art and a science.

In this article, we’ll dive deep into the costs involved in building a high-performance 2JZ engine. We’ll break down the expenses, including parts, labor, and other associated costs, and analyze budget scenarios to help you plan effectively. Whether you’re aiming for a 500HP daily driver or a 1500HP track monster, this guide will provide the insights you need to make informed decisions.

Popular Questions We’ll Address:

- How much does it cost to build a 2JZ engine?

- What’s the cheapest way to build a reliable high-performance setup?

- Is a high-performance 2JZ build worth the investment?

Prepare to uncover everything you need to know about building a high-performance 2JZ engine—and how to maximize value at every step.

What Makes the 2JZ Engine Special?

The Toyota 2JZ engine has earned its reputation as one of the greatest engines in automotive history. But what exactly makes it so special? From its engineering brilliance to its aftermarket versatility, the 2JZ stands apart for several key reasons.

Unmatched Durability

The 2JZ engine was built to last. Its iron block is capable of withstanding immense stress, making it a popular choice for high-horsepower applications. Unlike many modern aluminum-block engines, the 2JZ’s design allows it to endure extreme heat and pressure without compromising reliability.

Key Features:

- Iron Block: Provides superior strength and resistance to warping under high boost pressures.

- Stock Resilience: A stock 2JZ-GTE engine can handle 500-600 HP without major upgrades.

Incredible Tuning Potential

The 2JZ is famous for its ability to produce jaw-dropping horsepower numbers. With proper upgrades, this engine can comfortably exceed 1000 HP, and in extreme builds, reach as high as 1500 HP or more. The availability of performance parts—from forged internals to high-flow turbos—makes the 2JZ a tuner’s dream.

Popular Applications:

- Drifting: Torque-rich and reliable for aggressive driving styles.

- Drag Racing: Capable of massive power outputs for quarter-mile domination.

- Street Performance: Ideal for enthusiasts looking to blend power with daily drivability.

Strong Aftermarket Support

One of the biggest reasons for the 2JZ’s continued popularity is the extensive aftermarket support it enjoys. From big-name brands like GReddy and HKS to smaller boutique manufacturers, there’s no shortage of parts and expertise available. This accessibility simplifies the process of upgrading and maintaining the engine, regardless of your performance goals.

Aftermarket Advantages:

- Endless supply of parts for nearly any budget.

- Global community of tuners and mechanics who specialize in 2JZ builds.

Cultural and Historical Impact

Originally powering the Toyota Supra MK4, the 2JZ gained legendary status thanks to its appearances in movies like The Fast and the Furious and its dominance in the tuner car scene. Its reputation as a performance icon has only grown over the decades, making it a badge of honor for enthusiasts who build one.

The 2JZ engine is more than just its specs—it’s a symbol of what’s possible with precision engineering and passion for performance. This foundation of strength, flexibility, and history sets the stage for understanding why so many choose the 2JZ for their high-performance builds.

Cost Breakdown of a High-Performance 2JZ Engine

Building a high-performance 2JZ engine involves numerous components and considerations. Each part of the engine plays a critical role in achieving the desired performance, and understanding the associated costs is essential for planning your build.

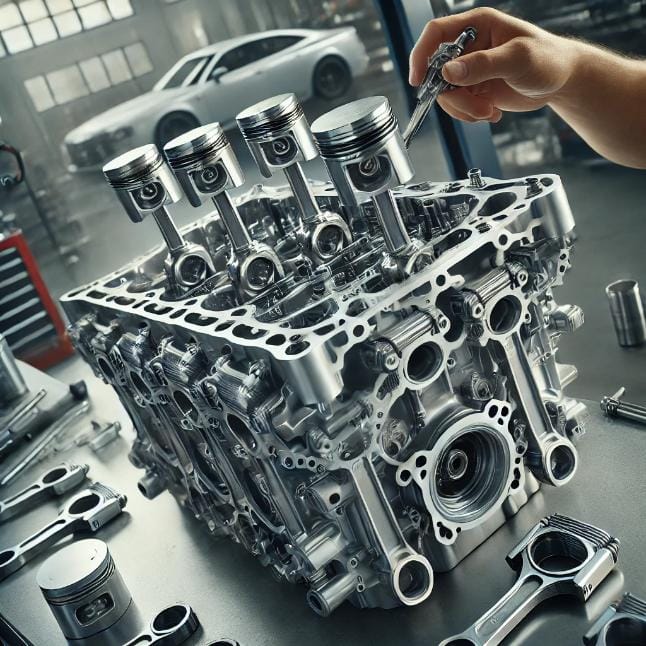

Short Block Components

The short block forms the foundation of the 2JZ engine. To handle high power, upgrading these components is often necessary.

- Pistons: Forged pistons are essential for high-compression and turbocharged builds.

- Cost Range: $600–$1,200

- Connecting Rods: Forged rods are designed to endure high torque and RPMs.

- Cost Range: $400–$1,000

- Crankshaft: The stock 2JZ crankshaft is robust, but aftermarket billet options are available for extreme builds.

- Cost Range: $500–$2,500

- Bearings and Gaskets: High-quality bearings and gaskets ensure durability under extreme conditions.

- Cost Range: $300–$700

Approximate Total (Short Block): $2,000–$5,000

Cylinder Head Components

The cylinder head controls airflow and combustion efficiency. Upgrades here are critical for optimizing performance.

- Cams and Camshafts: Higher lift and duration profiles improve airflow and power delivery.

- Cost Range: $800–$1,500

- Valves and Springs: Stronger valves and springs prevent valve float at high RPMs.

- Cost Range: $500–$1,200

- Porting and Polishing: Enhances airflow by optimizing intake and exhaust passages.

- Cost Range: $1,000–$2,000

Approximate Total (Cylinder Head): $2,300–$4,700

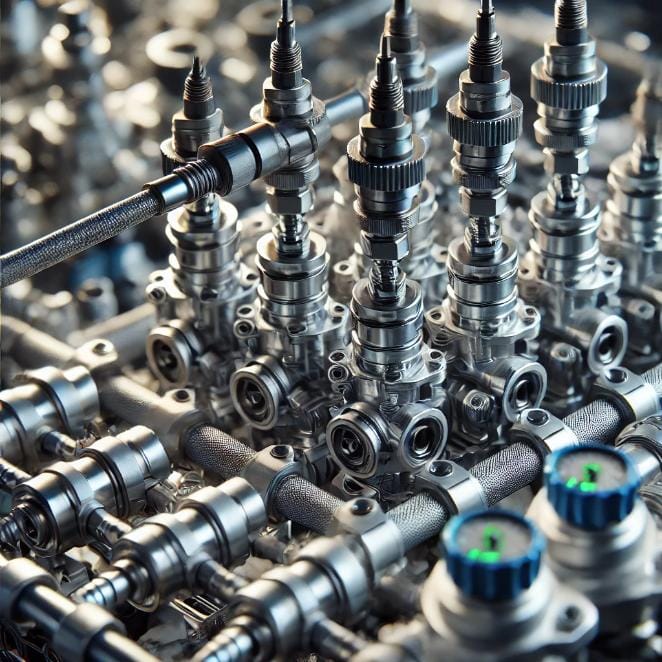

Forced Induction Options

A significant portion of the budget goes to forced induction systems, which are responsible for the massive power gains the 2JZ is known for.

- Single Turbo Setup: Popular for simplicity and peak power.

- Cost Range: $2,500–$4,000

- Twin Turbo Setup: Ideal for better response and broader powerband.

- Cost Range: $3,500–$6,000

- Turbo Manifold: Critical for mounting the turbo system.

- Cost Range: $500–$1,500

Approximate Total (Forced Induction): $3,500–$8,500

Supporting Systems

Supporting systems ensure reliability and performance under high power levels.

- Fuel System:

- Injectors, pumps, and regulators for optimal fuel delivery.

- Cost Range: $1,200–$2,500

- Cooling System:

- Radiators, oil coolers, and intercoolers to manage heat.

- Cost Range: $800–$2,000

- Ignition System:

- Upgraded coils and spark plugs for efficient combustion.

- Cost Range: $300–$800

Approximate Total (Supporting Systems): $2,300–$5,300

Transmission and Drivetrain

The drivetrain must be robust enough to handle the power and torque of a high-performance 2JZ.

- Gearbox: Options like the Getrag V160 or R154.

- Cost Range: $2,000–$7,000

- Clutch and Flywheel: Performance-grade options for smooth power delivery.

- Cost Range: $800–$2,000

Approximate Total (Transmission and Drivetrain): $2,800–$9,000

Miscellaneous Expenses

Small yet essential components add up to the overall cost.

- Tools and Consumables: Specialized tools, fluids, and fasteners.

- Cost Range: $300–$800

- Unforeseen Costs: Budget for troubleshooting and replacements.

- Estimated Buffer: $500–$1,000

Estimated Total Cost

Combining all components, the total cost for a high-performance 2JZ engine build typically falls between $10,000 and $25,000. Extreme builds can exceed $30,000 depending on the level of customization and quality of parts.

Labor Costs

While the parts for a high-performance 2JZ engine make up a significant portion of the budget, labor costs can be just as impactful. Proper assembly, machining, and tuning are essential to ensure your build runs reliably and delivers the desired performance.

Engine Machining Costs

Machine work is a critical step in preparing the engine for high performance. This includes precision work to ensure all components fit and function flawlessly.

- Block Boring and Honing: Prepares the cylinder walls for new pistons and rings.

- Cost Range: $300–$800

- Head Resurfacing and Porting: Improves compression and airflow.

- Cost Range: $400–$1,500

- Crankshaft Balancing: Ensures smooth operation at high RPMs.

- Cost Range: $250–$500

- Total Machine Work Cost: $1,000–$3,000

Assembly Labor

Engine assembly labor costs vary depending on the level of expertise required. While some enthusiasts choose to assemble their engines at home, professional assembly is often recommended for high-performance builds.

- Professional Assembly: Ensures proper torque specs, tolerances, and seals.

- Cost Range: $1,500–$3,000

- DIY Assembly: Savings on labor costs but requires specialized tools and knowledge.

Tuning Costs

Proper tuning is crucial for unlocking the full potential of your 2JZ engine while maintaining reliability. Dyno tuning involves adjusting the ECU for optimal air-fuel ratios, ignition timing, and boost levels.

- Dyno Tuning: Conducted by professional tuners using advanced equipment.

- Cost Range: $500–$1,500 per session

- Retunes: Necessary after major changes to the setup.

- Cost Range: $300–$800

Regional Variances

Labor costs can vary significantly depending on your location and the shop’s expertise. High-end performance shops with extensive experience in 2JZ builds may charge premium rates, but their quality of work often justifies the expense.

- Average Hourly Rates:

- Standard Shops: $75–$125/hour

- Performance Specialists: $150–$250/hour

Estimated Total Labor Costs

Depending on the complexity of the build and the expertise required, total labor costs for a high-performance 2JZ engine can range from $3,000 to $7,000 or more. Factoring in potential retunes and additional adjustments is crucial to budgeting accurately.

Real-World Budget Scenarios

Understanding how different budgets affect a 2JZ engine build is crucial for setting realistic expectations. Here, we break down three common build scenarios: entry-level, mid-range, and high-end. Each scenario highlights the typical costs, components, and performance outcomes.

Entry-Level Build (~500 HP)

For enthusiasts seeking a reliable and modestly powerful 2JZ engine, an entry-level build is the way to go. This setup is ideal for daily driving with occasional spirited use.

- Key Components:

- Stock internals with minor upgrades (e.g., forged pistons and rods).

- Single turbo kit with moderate boost (Garrett or BorgWarner).

- Basic fuel system upgrades (injectors and pump).

- Stock ECU with a piggyback tuning solution.

- Basic supporting mods (intercooler, clutch, exhaust).

- Cost Breakdown:

- Parts: $4,000–$7,000

- Labor: $2,000–$3,000

- Total: $6,000–$10,000

- Performance Expectations:

- Horsepower: ~500 HP

- Reliability: High with moderate boost levels.

Mid-Range Build (~1,000 HP)

A mid-range build pushes the 2JZ’s capabilities significantly, balancing performance and reliability. This setup suits enthusiasts looking for track performance with occasional street driving.

- Key Components:

- Forged internals (rods, pistons, and billet crankshaft if needed).

- High-performance turbo (e.g., Precision or GReddy).

- Advanced fuel system with high-flow injectors and dual pumps.

- Standalone ECU for full control over tuning parameters.

- Upgraded cooling system (radiator, intercooler, oil cooler).

- Reinforced drivetrain (clutch, flywheel, and transmission upgrades).

- Cost Breakdown:

- Parts: $10,000–$15,000

- Labor: $4,000–$6,000

- Total: $14,000–$21,000

- Performance Expectations:

- Horsepower: ~1,000 HP

- Reliability: Moderate; regular maintenance required.

High-End Build (1,500+ HP)

For those chasing extreme power and performance, a high-end build leaves no room for compromise. This is the ultimate setup for competitive racing or showcasing engineering prowess.

- Key Components:

- Fully forged internals with billet block and head options.

- Custom turbo setup with large single turbos or advanced twin systems.

- Comprehensive fuel system capable of handling E85 or race fuel.

- Advanced ECU with custom dyno tuning.

- Reinforced drivetrain with sequential transmission.

- Full array of supporting systems (cooling, ignition, exhaust).

- Cost Breakdown:

- Parts: $20,000–$30,000+

- Labor: $6,000–$10,000+

- Total: $26,000–$40,000+

- Performance Expectations:

- Horsepower: 1,500+ HP

- Reliability: Low to moderate; highly dependent on maintenance and tuning.

Key Takeaways for Budget Scenarios

- Entry-Level Builds offer the best balance of cost and reliability, ideal for new enthusiasts.

- Mid-Range Builds are perfect for track-ready vehicles with serious performance goals.

- High-End Builds cater to professionals and serious competitors who demand peak performance.

DIY vs. Professional Builds

One of the biggest decisions in a high-performance 2JZ engine build is whether to handle the project yourself or rely on professionals. Both approaches have distinct advantages and drawbacks, depending on your skill level, budget, and performance goals.

DIY Builds

A do-it-yourself build appeals to enthusiasts who want to save on labor costs and gain hands-on experience. While it can be a rewarding endeavor, it requires significant preparation, tools, and knowledge.

Advantages of DIY:

- Cost Savings: Avoid professional labor fees, saving thousands of dollars.

- Learning Opportunity: Gain invaluable mechanical skills and a deeper understanding of your engine.

- Customization: Full control over every component and process.

Challenges of DIY:

- Specialized Tools: Requires tools like torque wrenches, engine stands, and precision measuring instruments.

- Tool Costs: ~$500–$2,000.

- Time Commitment: Building an engine can take weeks or months, especially for beginners.

- Risk of Errors: Mistakes during assembly or tuning can lead to costly damage.

Best Suited For:

- Enthusiasts with prior mechanical experience.

- Builds under 500–800 HP, where tolerances are more forgiving.

Professional Builds

Relying on experienced shops ensures a high-quality result, especially for complex or high-power setups. Performance specialists often have decades of experience with 2JZ engines.

Advantages of Professional Builds:

- Expertise: Professionals can handle precise tolerances, machining, and tuning.

- Time Efficiency: A shop can complete the project faster than most DIY efforts.

- Warranty: Many shops offer guarantees on their work, providing peace of mind.

Challenges of Professional Builds:

- Higher Costs: Labor fees for assembly, machining, and tuning add significantly to the budget.

- Less Control: You may have limited input on the process unless working with a highly collaborative shop.

Best Suited For:

- Builds exceeding 800 HP, where precision is critical.

- Enthusiasts who prefer convenience over hands-on involvement.

Hybrid Approach

For some builders, a hybrid approach offers the best of both worlds. You can handle simpler tasks, like disassembly or sourcing parts, while leaving the complex work to professionals.

Example Tasks for DIY:

- Removing the engine from the vehicle.

- Cleaning parts and prepping the block.

- Installing bolt-on components like turbos and exhaust systems.

Example Tasks for Professionals:

- Machining and balancing internal components.

- Head porting and tuning on a dyno.

Cost Comparison

| Build Type | Approximate Cost | Time Required | Skill Level Needed |

| DIY Build | $8,000–$15,000 | 1–3 months | Advanced (for high HP) |

| Professional Build | $15,000–$25,000+ | 1–2 weeks (shop time) | None (expert work done) |

| Hybrid Approach | $10,000–$20,000 | Varies | Intermediate |

Key Takeaways for DIY vs. Professional Builds

- DIY builds are cost-effective and satisfying for smaller projects, but they demand expertise.

- Professional builds are ideal for high-stakes performance goals but come at a premium.

- A hybrid approach offers flexibility, balancing cost savings and professional reliability.

Comparison with Other Performance Engines

When considering building a high-performance engine, the 2JZ often enters the conversation alongside other iconic powerplants. To help you make an informed decision, let’s compare the 2JZ with other popular performance engines in terms of cost, performance, and overall value.

2JZ vs. RB26DETT

The RB26DETT is another legendary engine known for its tuning potential and reliability. It’s commonly found in the Nissan Skyline, making it a direct competitor to the 2JZ for high-performance builds.

Key Comparisons:

- Cost:

- 2JZ: Generally less expensive for initial builds, with a broader aftermarket parts market.

- RB26: Can be more expensive due to fewer aftermarket parts and increased difficulty sourcing parts in some regions.

- Cost Range for Similar Builds:

- 2JZ: $10,000–$20,000

- RB26: $12,000–$22,000

- Performance Potential:

- 2JZ: Known for exceeding 1,000 HP reliably with minimal internal upgrades.

- RB26: Also capable of 1,000+ HP but requires more internal upgrades (e.g., strengthened block).

- Availability and Aftermarket Support:

- 2JZ: Extensive support from brands like GReddy, HKS, and AEM.

- RB26: Fewer options compared to the 2JZ, but still significant for Nissan enthusiasts.

Conclusion:

The 2JZ offers a more cost-effective and widely supported platform, making it a better choice for most enthusiasts, especially when considering the power-to-cost ratio.

2JZ vs. LS3 (Chevy V8)

The LS3 is one of the most popular V8 engines for performance builds, thanks to its large displacement and ease of modification. It’s often compared to the 2JZ for projects where high horsepower is the primary goal.

Key Comparisons:

- Cost:

- 2JZ: More expensive for the engine block and high-quality internals.

- LS3: Typically cheaper for stock engine blocks, but costs can rise quickly with modifications.

- Cost Range for Similar Builds:

- 2JZ: $10,000–$25,000+

- LS3: $7,000–$20,000+ (depending on level of modifications)

- Performance Potential:

- 2JZ: Greater reliability at high RPMs, making it ideal for setups with forced induction.

- LS3: Easy to build to 1,000 HP with a large displacement advantage. However, may need more modifications for forced induction builds.

- Weight and Packaging:

- 2JZ: Lighter and smaller, making it easier to fit into a variety of vehicles, including smaller platforms like the Toyota Supra.

- LS3: Heavier, often requiring significant modifications to the engine bay for fitment.

Conclusion:

The LS3 offers more power for the dollar when considering large-displacement builds but lacks the 2JZ’s reputation for reliability and high-revving performance. If you’re looking for a smoother and more reliable platform at higher RPMs, the 2JZ might be the better choice.

7.3 2JZ vs. VR38DETT (Nissan GT-R)

The VR38DETT is the engine found in the Nissan GT-R and is known for its sophisticated technology and high performance. It competes with the 2JZ for those seeking extreme power output and durability.

Key Comparisons:

- Cost:

- 2JZ: Lower initial cost, with plenty of aftermarket support for builds up to 1,500 HP.

- VR38: Higher initial cost and more expensive to modify, often requiring specialized parts and tuning.

- Cost Range for Similar Builds:

- 2JZ: $15,000–$30,000

- VR38: $20,000–$40,000

- Performance Potential:

- 2JZ: Proven reliability at over 1,000 HP with less internal modification.

- VR38: Can achieve similar power figures but at a higher cost and complexity.

- Technology and Features:

- 2JZ: While the 2JZ is mechanically robust, it’s less advanced in terms of modern tech compared to the VR38.

- VR38: Comes with advanced features like twin turbochargers, direct injection, and a more modern architecture that offers efficiency at extreme power levels.

Conclusion:

The 2JZ remains a more affordable and accessible option, especially for enthusiasts looking for proven results in the aftermarket world. The VR38 is a superior choice for those who want cutting-edge technology and are willing to invest more money into a Nissan GT-R build.

2JZ vs. Hemi V8 (Dodge)

The Hemi V8 is another competitor in the high-performance engine space, popular for muscle car builds. While the Hemi excels in low-end torque, its comparison with the 2JZ is interesting for enthusiasts who want to build an all-around powerhouse.

Key Comparisons:

- Cost:

- 2JZ: Generally less expensive for the base engine, especially in terms of performance mods.

- Hemi V8: Slightly more expensive for stock performance, with higher costs for modifications.

- Cost Range for Similar Builds:

- 2JZ: $10,000–$25,000+

- Hemi V8: $12,000–$30,000+

- Performance Potential:

- 2JZ: Exceptional at handling high RPMs and forced induction.

- Hemi V8: Powerful in the lower RPM range, but often requires more modifications for higher-revving builds.

- Aftermarket Support:

- 2JZ: Offers broad aftermarket support and knowledge from Toyota Supra owners.

- Hemi V8: Strong aftermarket for Mopar vehicles, but less established in terms of high-RPM performance.

Conclusion:

The Hemi V8 is a great engine for low-end torque and muscle car enthusiasts, but the 2JZ offers superior capabilities in forced induction and high-RPM power output.

Key Takeaways for Engine Comparison

- The 2JZ stands out for its balance of affordability, durability, and high-performance potential.

- RB26 offers similar performance but is often more expensive and harder to source parts for.

- LS3 provides excellent value for the power output but lacks the high-revving reliability of the 2JZ.

- The VR38 and Hemi V8 are fantastic for extreme builds but come with higher costs and more complex modifications.

Frequently Asked Questions (FAQs)

How Much Does It Cost to Build a 2JZ Engine?

Building a 2JZ engine can cost anywhere between $6,000 to $30,000, depending on the performance level you’re aiming for and the components you choose. Entry-level builds for 500 HP can cost around $6,000 to $10,000, while extreme builds pushing 1,500 HP can exceed $30,000. This includes the costs of parts, labor, tuning, and other supporting systems like fuel and cooling.

How Much Does It Cost to Turbo a 2JZ?

Turbocharging a 2JZ engine can cost between $2,500 to $8,000, depending on whether you go for a single or twin-turbo setup. The cost includes the turbochargers, manifold, piping, intercooler, and other necessary components. The exact cost depends on your performance goals (e.g., 400 HP vs. 1,000+ HP) and the quality of the parts.

What is the Cheapest Way to Build a Reliable 2JZ?

The most cost-effective way to build a reliable 2JZ engine is by keeping the stock internals (pistons, rods, crankshaft) and focusing on a modest turbo setup, upgraded fuel system, and tuning. Using high-quality aftermarket parts for critical components like injectors, fuel pump, and turbo can help maximize reliability without breaking the bank. Typically, a budget build can be achieved for around $6,000 to $8,000.

Is a 2JZ Engine Worth Building?

Yes, a 2JZ engine is definitely worth building for enthusiasts focused on high performance and long-term reliability. Known for its exceptional strength and tuning potential, the 2JZ can handle significant power upgrades without sacrificing reliability. Whether you’re looking to build a streetcar or a track monster, the 2JZ offers a great balance of power, durability, and aftermarket support.

How Long Does It Take to Build a 2JZ Engine?

Building a 2JZ engine can take anywhere from 1 month to 3 months, depending on whether you’re doing it yourself or working with a professional shop. A professional build with all the necessary tuning and dyno sessions will likely take between 1–2 months. DIY builds can take longer, especially if you’re waiting on parts or need time to troubleshoot.

What’s the Cost to Rebuild a 2JZ-GTE?

Rebuilding a 2JZ-GTE, including replacing worn parts and machining the block, can cost between $3,000 and $6,000. This rebuild cost includes things like honing the cylinders, balancing the crankshaft, replacing seals, gaskets, and bearings, as well as labor costs. More extensive rebuilds with performance upgrades will increase the cost.

What’s the Difference Between 2JZ-GTE and 2JZ-GE Builds?

The 2JZ-GTE is the turbocharged version of the 2JZ engine, and it’s built for more extreme performance goals. On the other hand, the 2JZ-GE is naturally aspirated, making it easier and cheaper to build. While the 2JZ-GTE can easily be upgraded to handle 1,000+ horsepower with minimal internal modifications, the 2JZ-GE will require more significant upgrades to reach similar power levels, such as forced induction setups and stronger internals. The cost to build a 2JZ-GE is typically lower than building a 2JZ-GTE.

What Parts Are Needed for a High-Performance 2JZ Build?

A high-performance 2JZ build requires:

- Forged Pistons and Rods for handling high boost and RPM.

- Upgraded Turbochargers for significant power gains.

- Fuel System Upgrades (injectors, pump, regulators).

- Cooling System (intercooler, radiator, oil cooler).

- Stronger Crankshaft and Bearings for extreme builds.

- Standalone ECU for precise tuning.

- Reinforced Transmission to handle high horsepower.

How Much Does Dyno Tuning Cost for a 2JZ Engine?

Dyno tuning costs for a 2JZ engine typically range from $500 to $1,500, depending on the complexity of the build and the tuning shop’s expertise. Tuning is essential to ensure that your engine runs efficiently and reliably at high power levels, optimizing parameters such as air-fuel ratio, ignition timing, and boost levels.

Tips for Saving Money

Building a high-performance 2JZ engine can be a significant investment, but there are ways to minimize costs without compromising on quality. Here are some expert tips and strategies for saving money while still achieving impressive results.

Sourcing Affordable Parts

One of the biggest expenses when building a 2JZ engine is the cost of parts. While it’s tempting to buy the best of everything, there are smart ways to source affordable yet reliable components.

- Buy Used or Refurbished Parts:

- Many 2JZ enthusiasts and shops sell used or refurbished parts that are still in great condition. Popular forums like Supraforums and other automotive communities are good places to find deals.

- Best Sourced Parts: Turbochargers, injectors, and fuel pumps can often be bought used and still perform well.

- Shop for Deals During Off-Seasons:

- Many aftermarket parts suppliers offer discounts during the off-season (typically winter months) or during special sales events like Black Friday or Cyber Monday.

- Tip: Always keep an eye on major online retailers and sign up for alerts.

- Consider Aftermarket Brands:

- While OEM parts are high-quality, aftermarket brands like eBay’s Performance Parts or brands such as Vibrant Performance and Kelford Cams can offer great performance at a lower cost.

- Tip: Look for parts that offer similar quality but are priced more reasonably.

Do Some Work Yourself

While building a 2JZ engine yourself isn’t for everyone, if you have the right skills, there are several areas where you can save money by doing the work yourself.

- Disassembly and Assembly:

- Taking apart the engine and reassembling it is a time-consuming but relatively straightforward task. If you have basic mechanical skills, this can save you hundreds of dollars in labor fees.

- Tip: Be sure to document every step to avoid mistakes. Detailed guides and videos can help you through the process.

- Prep and Clean Parts:

- Many high-performance builds require cleaning and prepping engine parts like the block, pistons, and cylinder head. This can be done yourself with some time and elbow grease, avoiding costly machine shop fees.

- Tip: Use a parts cleaner and feel free to DIY the valve spring replacement if you have the right tools.

Shop Around for Labor

If you prefer to leave the technical work to professionals, be sure to shop around for labor quotes. Not all performance shops charge the same rates, and pricing can vary depending on the region and expertise.

- Get Multiple Quotes:

- Labor costs can vary dramatically, so always get at least 3 quotes from different shops before committing to a particular one. Make sure the shop has experience with high-performance 2JZ builds.

- Tip: Sometimes, specialized shops charge more for their expertise, but the cost is justified by their high-quality work.

- Negotiate for Discounts:

- Don’t be afraid to ask for a discount, especially if you’re getting multiple services (e.g., machining, assembly, and tuning) done at the same shop.

- Tip: Look for shops that offer package deals or promotions.

Use a Hybrid Approach

For those who don’t want to go the full DIY route but still want to save money, a hybrid approach is ideal.

- DIY the Basics, Professionalize the Complex:

- You can handle less technical tasks like disassembling the engine, sourcing parts, and even assembling the short block. The more complex tasks like head porting, machining, and dyno tuning should be left to professionals.

- Tip: Using this hybrid approach can save you $1,000–$5,000 depending on the labor involved.

- Outsource to Experts When Needed:

- Focus your DIY efforts on areas you can confidently handle. Leave the specialized machining and high-end tuning to the experts.

- Tip: Always be realistic about your skill level. A poorly done DIY job can cost you more in the long run due to mistakes.

Consider Alternative Power Options

While the 2JZ engine is known for its immense potential, some builds may benefit from alternative power-boosting strategies that don’t involve heavy spending on high-end parts.

- E85 Fuel:

- If your goal is to run higher power on a budget, consider using E85 fuel. E85 offers better cooling and more octane, allowing you to push the engine further without spending a fortune on expensive fuel system upgrades.

- Tip: You’ll need bigger injectors and a fuel pump, but the overall cost is lower compared to more expensive race fuels.

- Used Turbos and Supporting Systems:

- Opt for used turbochargers and intercoolers that have been cleaned, tested, and refurbished. These can often provide the same performance at a fraction of the cost.

- Tip: Ensure that the used parts you purchase come from reputable sellers and that they are in good working condition.

Key Takeaways for Saving Money

- Sourcing affordable, used, or aftermarket parts can significantly reduce your overall build cost.

- Doing some of the work yourself—such as disassembly or prep work—can save you hundreds to thousands of dollars.

- Shopping around for labor and negotiating can cut your professional costs in half.

- A hybrid approach (DIY for basics, professional for complex tasks) offers a perfect balance of savings and quality.

Conclusion

Building a high-performance 2JZ engine is a thrilling and rewarding experience for any automotive enthusiast. Whether you’re building it for street use, racing, or simply as a passion project, the 2JZ offers an unmatched combination of durability, tunability, and aftermarket support. However, the process comes with significant costs, and careful planning is essential to avoid breaking the bank.

Key Points to Remember:

- Parts and Labor: The cost of building a high-performance 2JZ engine can vary greatly, with entry-level builds ranging from $6,000 to $10,000 and extreme builds potentially exceeding $30,000. Understanding where to invest—whether in high-quality parts or professional labor—is key to making your build both cost-effective and powerful.

- Budgeting: Realistic budgeting is essential. Entry-level builds focus on reliability with moderate power (500 HP), mid-range builds push performance to around 1,000 HP, and high-end builds are designed to exceed 1,500 HP with extreme modifications. Each budget tier has its own set of challenges and costs.

- Labor and DIY: Whether you choose a DIY build or hire professionals, understanding labor costs is crucial. DIY builds can save you money but require significant time and expertise, while professional builds offer precision and reliability, albeit at a higher price.

- Smart Sourcing: Smart shopping for parts and services can drastically reduce the overall cost of your build. From buying used parts to shopping around for labor quotes, these small changes can add up to big savings without compromising on quality.

- Aftermarket Support and Customization: One of the strongest advantages of the 2JZ engine is the extensive aftermarket support. Whether you’re looking for custom turbo kits, forged internals, or fuel systems, the options are abundant. This means you can customize your build to your exact specifications while keeping costs in check.

Final Thoughts:

A 2JZ engine build is not just about horsepower—it’s about creating a reliable and exciting machine that you can proudly drive, race, or show off. While the costs can be significant, careful planning, smart sourcing, and a hybrid approach to DIY and professional work can help you get the best bang for your buck. The journey of building a 2JZ is one of passion, patience, and precision, but the results are always worth it.

Now that you have a comprehensive understanding of the costs involved in building a high-performance 2JZ engine, you’re better equipped to begin your project. Whether you’re working on a budget build or aiming for a record-breaking 1,500 HP monster, you’ll be able to make informed decisions every step of the way.

Ready to start your 2JZ build? Share your plans, ask any remaining questions, and get in touch with other enthusiasts—there’s always more to learn in the world of high-performance builds!