Understanding the 2JZ Platform

What Makes the 2JZ Legendary?

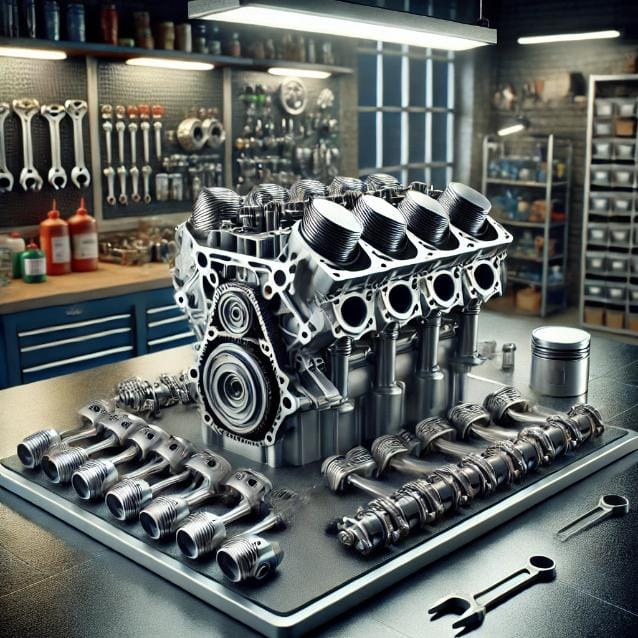

The Toyota 2JZ engine has gained legendary status among car enthusiasts and tuners for its unparalleled durability, power potential, and versatility. Introduced in the 1990s and featured in iconic cars like the Toyota Supra MK4, the 2JZ became a symbol of reliability and performance.

Key Features of the 2JZ Engine:

- Cast-Iron Block: The 2JZ engine’s robust cast-iron block ensures exceptional strength, allowing it to handle extreme levels of horsepower without compromising durability.

- Forged Internals: Stock 2JZ engines come equipped with forged crankshafts and rods, capable of enduring significant stress.

- Turbocharged Power: The 2JZ-GTE variant includes twin turbochargers, delivering impressive performance out of the box and offering room for modification.

- Over-Engineering: Toyota’s attention to detail in designing the 2JZ makes it ideal for high-performance applications, with features like oil squirters for cooling pistons and strong main caps.

2JZ-GTE vs. 2JZ-GE: What’s the Difference?

While both variants share the same fundamental architecture, their intended purposes and performance capabilities differ.

- 2JZ-GTE:

- Equipped with twin sequential turbochargers.

- Designed for high-performance vehicles like the Supra and Aristo.

- Includes oil squirters and a lower compression ratio, making it more suitable for forced induction.

- 2JZ-GE:

- Naturally aspirated variant, found in vehicles like the Lexus IS300.

- Higher compression ratio for better efficiency in NA applications.

- Fewer reinforcements compared to the GTE but still offers solid reliability.

Why 2JZ Engines Are Ideal for Modifications

The 2JZ engine is a favorite in the tuning world due to:

- Its ability to handle up to 800–1,000 HP with stock internals when properly tuned.

- Compatibility with a wide range of aftermarket parts.

- A global community of enthusiasts sharing build insights, making information and support easily accessible.

Knowing Your Build Goals

Before starting a 2JZ project, it’s crucial to define your objectives. Building a high-performance engine without a clear purpose often leads to wasted resources and potential reliability issues.

- Types of Builds:

- Street Build: Balanced modifications for daily driving reliability with moderate power gains (~400–600 HP).

- Track Build: High-horsepower setups with supporting mods for circuit or drag racing (~700–1,000+ HP).

- Show Build: Focus on aesthetics with polished parts and custom detailing.

- Setting Realistic Power Goals:

- Aim for incremental gains rather than jumping straight to extreme horsepower figures.

- Consider supporting modifications like fuel systems, cooling, and drivetrain upgrades to align with your power targets.

Common Mistakes During Planning

Lack of Research and Goal Setting

One of the most frequent pitfalls for 2JZ engine builders is diving into a project without proper planning. A lack of clear objectives and research often results in wasted time, money, and effort.

Key Issues:

- Unrealistic Expectations: Many enthusiasts overestimate what they can achieve with their budget or experience level. For instance, attempting a 1,000 HP build without understanding the necessary supporting modifications is a recipe for disaster.

- Overlooking Details: Failing to research torque specs, proper installation techniques, and compatibility between components can lead to assembly errors.

Solutions:

- Define clear objectives, such as your intended power level, purpose (street, track, or show), and budget.

- Spend time researching reliable sources like forums, manuals, and professional tuners.

Not Understanding Part Compatibility

One of the most costly mistakes in a 2JZ build is using parts that are incompatible or poorly matched. With so many aftermarket options available, selecting the wrong components can significantly impact performance and reliability.

Examples of Common Compatibility Issues:

- Turbo Selection:

- Mismatched turbochargers can cause issues like lag, insufficient boost, or engine stress.

- Example: Using a large single turbo for a daily driver leads to excessive turbo lag and poor drivability.

- Piston and Rod Combinations:

- Selecting pistons and rods that don’t align with your build goals or compression requirements can lead to premature wear or failure.

- Example: Choosing high-compression pistons for a forced-induction build without proper tuning.

- Gasket Choices:

- Using the wrong head gasket for high-boost applications often leads to leaks or engine damage.

- Recommendation: Stick to high-performance options like ARP head studs and GTE head gaskets for forced induction.

Solutions:

- Create a build sheet outlining all required components and verify their compatibility with your 2JZ variant.

- Consult professionals or forums with extensive experience in 2JZ builds to ensure proper part selection.

Overlooking the Budget

An underestimated budget can derail even the most well-planned builds. Many enthusiasts focus on core components like the turbo and internals while forgetting essential upgrades.

Key Areas Often Overlooked:

- Supporting Modifications: Upgraded fuel systems, ECUs, cooling systems, and drivetrain components.

- Professional Services: Costs for machining, tuning, and dyno sessions.

Solutions:

- Plan your budget realistically, accounting for all parts, labor, and unexpected expenses.

- Include a buffer (around 15–20%) to cover unforeseen issues.

Neglecting to Consider Legal and Practical Constraints

Ignoring local laws and practical constraints can lead to frustration later in the build process.

Examples:

- Building an engine that doesn’t comply with emissions standards can make your car illegal for street use.

- Creating a high-horsepower build without considering heat management for daily driving conditions.

Solutions:

- Research emissions regulations and ensure your build adheres to them.

- Design your build around your intended use (e.g., a track car doesn’t need to pass emissions testing).

Choosing the Right Components

Turbocharging Mistakes

Turbocharging is one of the most exciting aspects of a 2JZ build, but selecting the wrong turbocharger can severely impact performance and drivability.

Common Turbocharging Errors:

- Oversized Turbochargers:

- Leads to excessive turbo lag, making the car sluggish in low RPM ranges.

- Example: Choosing a 76mm turbo for a street build when a 58–62mm option would deliver better drivability.

- Underestimating Boost Control:

- Inadequate boost controllers can result in inconsistent performance or engine damage.

- Solution: Invest in a quality electronic boost controller for precise adjustments.

- Ignoring Supporting Mods:

- Upgraded turbos require matching upgrades, such as larger intercoolers, exhaust manifolds, and downpipes.

Pro Tip: Match your turbo size to your power goals and usage. For street builds, focus on quick spool times and mid-range torque; for track builds, prioritize peak horsepower.

Skimping on Supporting Mods

Many builders focus on the core engine components but neglect the systems that support their functionality. This can cause bottlenecks and reliability issues.

Essential Supporting Modifications:

- Fuel System:

- Upgraded injectors, fuel pumps, and regulators are mandatory for high-horsepower builds.

- Example: Use 1,000cc injectors for power goals exceeding 500 HP.

- Cooling System:

- Increased power generates more heat, which can overwhelm the stock cooling system.

- Recommendation: Upgrade to aluminum radiators, larger intercoolers, and oil coolers.

- Drivetrain:

- Stock transmissions like the A340E may not handle increased power.

- Upgrade Options: CD009 (Nissan) or T-56 (GM) transmissions for high-horsepower applications.

Choosing Quality Internals

Key Internal Components:

- Pistons and Rods:

- Stock internals can handle ~600 HP, but beyond that, forged components are necessary.

- Recommendation: Brands like CP Pistons and Carrillo Rods are trusted for durability.

- Gaskets and Fasteners:

- Use high-performance head gaskets and ARP head studs to prevent head lifting under high boost.

- Bearings and Seals:

- Upgrade to performance-grade bearings to withstand higher RPM and stress levels.

The Importance of Machining and Blueprinting

Precise machining and blueprinting are vital for ensuring your engine operates efficiently and reliably.

Common Machining Mistakes:

- Over-Boring:

- Excessive cylinder boring can weaken the block and compromise reliability.

- Solution: Use a qualified machinist experienced with 2JZ engines.

- Improper Decking:

- Uneven surfaces can lead to head gasket failure.

- Solution: Ensure proper deck preparation for high-boost applications.

Pro Tip: Always consult machinists who specialize in high-performance engines and understand 2JZ tolerances.

Exhaust System Considerations

A restrictive exhaust system can limit performance and cause excessive backpressure.

Upgrades to Consider:

- Larger-diameter exhaust piping (e.g., 3–4 inches).

- High-flow catalytic converters or test pipes for track applications.

- Turbo manifolds designed for optimal flow and reduced lag.

Avoiding Electrical and ECU Mistakes

A powerful engine needs equally capable electronics to run efficiently.

ECU Upgrades:

- Standalone ECUs: Options like Haltech or AEM provide complete control over tuning.

- Piggyback ECUs: Less expensive but limited in functionality compared to standalone options.

Common Wiring Mistakes:

- Improper grounding and poor connections can lead to intermittent issues.

- Solution: Use high-quality wiring kits and follow a clean, organized installation process.

Assembly Errors

Incorrect Assembly Techniques

The assembly process is where all your preparation and parts selection come together. Errors at this stage can result in catastrophic engine failure, even with top-tier components.

Common Assembly Mistakes:

- Ignoring Torque Specifications:

- Over- or under-tightening bolts can lead to warped components or insufficient sealing.

- Solution: Always follow the manufacturer’s torque specs, especially for critical areas like head bolts and main bearings.

- Improper Gasket Installation:

- Misaligned or poorly seated gaskets can cause leaks.

- Recommendation: Use high-quality gaskets and double-check alignment during installation.

- Incorrect Timing Setup:

- Mistiming the camshafts can result in poor performance or engine damage.

- Solution: Use a timing light and proper tools to ensure accuracy.

Skipping Professional Machining

Precision is key to achieving reliable performance from a high-powered 2JZ engine. Attempting to bypass professional services often leads to avoidable problems.

Examples of Skipped Machining Errors:

- Cylinder Wall Finish:

- Poor honing can lead to improper piston ring sealing, increasing oil consumption.

- Solution: Ensure proper surface roughness for your specific piston and ring combination.

- Deck Surface Preparation:

- Uneven or rough surfaces cause head gasket failures, especially under boost.

- Solution: Request a smooth RA (Roughness Average) finish suited for MLS (multi-layer steel) head gaskets.

Pro Tip: Provide your machinist with the exact specs and goals for your build. Communication is essential.

Neglecting Break-In Procedures

How you treat the engine during its break-in period has a lasting impact on performance and longevity.

Key Steps for Proper Break-In:

- Initial Oil Selection:

- Use a break-in oil with high zinc and phosphorus content to protect new components.

- Example: Joe Gibbs Driven BR30 is a popular choice.

- RPM Variation:

- Avoid prolonged idling or steady RPMs during the first 500–1,000 miles.

- Alternate between light loads and moderate acceleration to seat the rings properly.

- Early Maintenance:

- Change the oil and filter after the first 50–100 miles to remove initial debris from new components.

Overlooking Blueprinting

Blueprinting ensures that all engine components meet exact specifications, reducing variability and maximizing efficiency.

What Blueprinting Involves:

- Checking and balancing rotating assemblies (crankshaft, rods, pistons).

- Ensuring exact tolerances for bearings and clearances.

- Aligning bores and honing cylinders for consistent performance.

Common Overlooked Aspects:

- Rod and crank journal alignment.

- Piston-to-valve clearance checks.

Pro Tip: Blueprinting may seem tedious, but it significantly enhances reliability and performance, especially in high-stress applications.

Assembly Environment and Tools

The environment and tools you use during assembly can make or break your build.

Best Practices:

- Clean Environment:

- Assemble your engine in a dust-free, organized workspace to prevent contamination.

- Specialized Tools:

- Use piston ring compressors, torque wrenches, and micrometers to ensure accuracy.

- Documentation:

- Maintain a checklist of each step completed during assembly.

Common Mistakes in Final Assembly

Examples:

- Skipping Lubrication: Failing to lubricate bolts, bearings, or seals leads to unnecessary friction and wear.

- Reusing Old Bolts: Always replace one-time-use fasteners like head bolts with ARP or similar performance-grade alternatives.

Final Check Before Startup:

- Rotate the engine by hand to verify smooth operation and ensure no binding or interference.

- Double-check timing, fluid levels, and connections before initial startup.

The Importance of Tuning

Why Proper Tuning is Critical

Tuning is the heart of achieving optimal performance and reliability in a 2JZ engine. A poorly tuned engine can lead to inefficiencies, overheating, or catastrophic failure, regardless of the quality of the components used.

Key Risks of Poor Tuning:

- Detonation (Knocking):

- Incorrect air-fuel ratios or ignition timing can cause detonation, leading to piston and valve damage.

- Solution: Use high-octane fuel and precise tuning to avoid detonation in forced-induction setups.

- Inefficient Fuel Mapping:

- Running too rich or too lean can decrease performance or harm the engine.

- Recommendation: Optimize the air-fuel ratio (AFR) for the desired powerband.

- Overheating:

- Ignition timing that’s too advanced can create excessive heat and stress on components.

- Solution: Monitor cylinder temperatures during tuning sessions to prevent overheating.

Essential Tools and Equipment for Tuning

ECU Options:

- Standalone ECUs:

- Examples: Haltech, AEM Infinity, and Link G4+.

- Benefits: Complete control over ignition, fuel mapping, boost, and sensors.

- Piggyback ECUs:

- Examples: GReddy E-Manage.

- Benefits: Cost-effective but less versatile than standalone options.

Additional Tools:

- Wideband O2 sensor for monitoring AFRs.

- Knock detection tools to identify detonation risks.

- Data logging systems for reviewing performance metrics.

Dyno Tuning vs. Road Tuning

Dyno Tuning:

- Advantages:

- Controlled environment for precise adjustments.

- Real-time power and torque measurements.

- Best For: High-performance builds requiring peak optimization.

Road Tuning:

- Advantages:

- Simulates real-world driving conditions.

- Allows fine-tuning for daily drivability.

- Best For: Street builds prioritizing drivability over peak numbers.

Pro Tip: Combine dyno and road tuning to strike a balance between peak performance and everyday usability.

Key Parameters to Optimize During Tuning

- Air-Fuel Ratio (AFR):

- Target AFR for 2JZ engines:

- Naturally Aspirated: ~12.5:1 under load.

- Turbocharged: ~11.5:1 under boost.

- Target AFR for 2JZ engines:

- Boost Levels:

- Stock 2JZ-GTE turbos can handle ~14 psi reliably.

- Higher boost levels require upgraded turbos and internal reinforcements.

- Ignition Timing:

- Adjust timing advance based on fuel quality and engine configuration.

- Advanced timing improves power but increases detonation risk.

- Rev Limiter:

- Set to protect components like rods and pistons.

- Example: Limit to ~7,500 RPM for street builds using stock internals.

Common Tuning Mistakes

- Overlooking Safety Features:

- Neglecting fail-safes like knock sensors or overboost protection can lead to damage.

- Solution: Configure safety features in the ECU for added protection.

- Rushing the Process:

- Tuning requires iterative adjustments and thorough testing.

- Solution: Dedicate ample time to each tuning phase.

- Ignoring Data Logging:

- Failing to analyze performance metrics results in missed optimization opportunities.

- Solution: Regularly review logs for parameters like AFR, knock, and boost.

Importance of Professional Tuning

DIY tuning can be tempting, but professional tuners bring expertise and equipment that ensure the best results.

Benefits of Professional Tuning:

- Access to advanced tools and dynos.

- Knowledge of 2JZ-specific configurations.

- Assurance of a safe and efficient build.

Recommended Tuning Practices

- Start with a conservative base map, especially for break-in periods.

- Gradually increase power levels to assess reliability.

- Regularly update and refine the tune based on driving habits and environmental conditions.

Advanced Modifications

Pushing the Limits of the 2JZ Engine

For enthusiasts aiming to achieve extreme performance, advanced modifications are essential. These upgrades allow the 2JZ engine to operate at its peak potential while maintaining reliability under high stress.

Reinforcing the Block

The stock cast-iron 2JZ block is robust, but extreme power levels require additional reinforcements.

Key Upgrades:

- Billet Main Caps:

- Strengthen the main bearing structure to handle high RPMs and boost.

- Ideal for builds exceeding 1,000 HP.

- Sleeving:

- Replacing cylinder walls with stronger sleeves increases durability under extreme boost levels.

- Necessary for builds targeting 1,200+ HP.

- Block Girdles:

- Distribute stress more evenly across the block.

- Reduces the likelihood of block distortion at high power levels.

Pro Tip: Consult with machinists experienced in high-performance engines to execute these upgrades properly.

Upgrading the Cylinder Head

The cylinder head plays a crucial role in maximizing airflow and combustion efficiency.

Essential Upgrades:

- Port and Polish:

- Improves airflow, enhancing power output across the RPM range.

- Focus on intake and exhaust ports for the best results.

- High-Performance Valvetrain:

- Upgraded valves, springs, and retainers to handle high RPM and boost pressures.

- Brands like Ferrea and Supertech offer reliable components.

- Camshafts:

- Custom cam profiles for increased lift and duration.

- Example: Choose mild cams for street use and aggressive cams for track builds.

Pro Tip: Balance airflow improvements with proper tuning to avoid powerband mismatches.

Forced Induction Enhancements

Turbocharger Selection:

- Large single turbos like BorgWarner EFR or Garrett GTX are common for extreme builds.

- Twin-turbo setups offer better spool characteristics for mid-range power.

Wastegate and Blow-Off Valves:

- External wastegates improve boost control, essential for maintaining consistent performance.

- Blow-off valves protect the turbo system by releasing excess boost pressure.

Intercooling:

- Upgrade to bar-and-plate intercoolers for better heat dissipation.

- Larger cores reduce intake temperatures, increasing air density and power.

Supporting Systems for High Performance

- Fuel System:

- Dual fuel pumps or high-flow in-tank options for adequate delivery.

- E85 compatibility requires upgraded injectors and fuel lines.

- Ignition System:

- Coil-on-plug setups improve spark energy and reduce misfires.

- Use high-performance spark plugs with the correct heat range for your application.

- Oil System:

- Dry sump systems prevent oil starvation during high-G maneuvers.

- High-capacity oil pans improve lubrication under extreme conditions.

Drivetrain and Transmission Upgrades

The stock drivetrain can’t handle extreme power levels without significant reinforcement.

Transmission Options:

- Getrag V160/V161: Handles up to 1,200 HP but is expensive and rare.

- CD009 (Nissan): Cost-effective and durable for high-horsepower builds.

- Tremec T-56 Magnum: Popular for drag racing applications.

Differential and Axles:

- Upgrade to limited-slip differentials for better traction.

- Reinforced axles and driveshafts prevent failures under high torque loads.

Maximizing Cooling Efficiency

Keeping temperatures in check is critical for reliability in advanced builds.

Cooling System Enhancements:

- Dual-pass aluminum radiators for increased coolant efficiency.

- Oil coolers with thermostatic control to prevent overcooling.

- Water-methanol injection kits for intake cooling and detonation prevention.

Advanced Electronics and Data Logging

Advanced builds require precise monitoring and control systems.

Standalone ECU Features:

- Real-time tuning and data logging.

- Advanced safety features like knock detection and fail-safes.

Data Acquisition Systems:

- Use sensors to monitor boost pressure, AFR, EGT (exhaust gas temperature), and oil pressure.

- Popular options include MoTeC and Racepak systems.

Advanced Troubleshooting

High-performance builds come with unique challenges.

Common Issues and Solutions:

- Boost Leaks:

- Regular pressure tests ensure consistent performance.

- Heat Soak:

- Addressed with proper heat shielding and thermal coatings.

- Drivetrain Failures:

- Use progressive power tuning to avoid overwhelming components.

Pro Tip: Advanced modifications require extensive testing and iterative tuning. Never rush this process, and work with professionals for precision.

Legal and Emissions Compliance

Understanding Legal and Emissions Requirements

Building a high-performance 2JZ engine is exciting, but overlooking legal and emissions compliance can lead to hefty fines, failed inspections, or even having your vehicle impounded. Ensuring your build aligns with local laws is crucial for both street legality and peace of mind.

Researching Local Emissions Standards

Key Areas to Investigate:

- Emission Levels:

- Understand the acceptable limits for carbon monoxide (CO), hydrocarbons (HC), and nitrogen oxides (NOx) in your region.

- Example: Many states in the U.S. require compliance with EPA standards or CARB (California Air Resources Board) regulations.

- Catalytic Converters:

- Retaining or upgrading catalytic converters is often mandatory for emissions compliance.

- High-flow catalytic converters can maintain emissions legality while supporting performance.

Pro Tip: Always check whether your region offers exemptions for classic or modified vehicles, as these rules can vary.

Noise Regulations

Performance exhaust systems can produce sound levels that exceed legal limits in some areas.

How to Stay Compliant:

- Use mufflers or resonators designed to reduce noise without compromising flow.

- Check local decibel limits for vehicles; some states cap sound at 95 dB(A) at specific RPM ranges.

Engine Swap Rules

Swapping a 2JZ engine into another vehicle may be subject to specific regulations.

Key Considerations:

- Chassis Compatibility:

- Verify that the vehicle can accommodate the 2JZ engine and supporting systems.

- Emissions Equipment:

- Retain all emissions control devices from the donor engine.

- Example: If swapping a 2JZ-GTE into a U.S. car, ensure the build includes the original catalytic converters and EGR (Exhaust Gas Recirculation) system.

Pro Tip: Some jurisdictions require inspections or certification for engine swaps. Obtain a “referee inspection” where applicable.

Insurance and Registration Challenges

A heavily modified or swapped vehicle may face hurdles during insurance or registration.

Steps to Address These Issues:

- Be transparent with your insurer about modifications to avoid voided policies.

- Provide detailed documentation of your build, including receipts and photographs, to streamline registration.

Keeping Your Build Street Legal

Practical Tips:

- Street vs. Track:

- Designate your car for either street or track use. Track-only vehicles often bypass emissions and noise regulations but cannot be legally driven on public roads.

- Documentation:

- Keep records of all modifications, especially emissions-related components.

- Consult Experts:

- Seek advice from professionals or local forums familiar with your region’s vehicle laws.

Balancing Compliance with Performance

Staying legal doesn’t have to mean sacrificing performance.

Compliance-Friendly Upgrades:

- High-flow catalytic converters to support emissions standards.

- Emissions-compliant ECUs that meet legal requirements while offering tuning flexibility.

- Quiet performance exhaust systems that reduce sound without significant power loss.

Pro Tip: Consider building multiple configurations for your vehicle: one optimized for street compliance and another for track performance.

Real-Life Example: Legal 2JZ Builds

Highlight examples of successful street-legal 2JZ swaps:

- A 2JZ-GTE swapped into a Lexus IS300 with all emissions components intact.

- A Toyota Supra built for California streets with a high-flow catalytic converter and compliant tuning.

Real-Life Case Studies

Lessons from Successful and Failed 2JZ Builds

Learning from real-world examples can provide valuable insights into what works and what doesn’t when building a 2JZ engine. These case studies highlight common mistakes, clever solutions, and critical lessons.

Case Study 1: A Reliable Daily Driver 2JZ-GTE Build

Overview:

- Goal: Build a street-legal, reliable daily driver with 500 HP.

- Vehicle: 1998 Toyota Supra.

- Challenges: Balancing power with drivability and emissions compliance.

Key Decisions:

- Turbo Selection: A small-to-medium-sized turbo (Garrett GTX3582R) for quick spool and minimal lag.

- Fuel System: Upgraded to 1,000cc injectors and a Walbro 450 fuel pump for adequate delivery.

- Cooling System: Installed a dual-pass aluminum radiator and an air-to-air intercooler.

- Tuning: Used an AEM Infinity standalone ECU for precise control and street-friendly tuning.

Outcome:

- Achieved 485 HP on pump gas with a smooth power curve and excellent street manners.

- Passed emissions testing using a high-flow catalytic converter and conservative tune.

Lesson: Prioritizing a balanced build and choosing compatible parts results in a reliable, enjoyable daily driver.

Case Study 2: A 1,200+ HP Track Monster

Overview:

- Goal: Maximize horsepower for drag racing while maintaining engine reliability.

- Vehicle: 1995 Toyota Supra.

- Challenges: Reinforcing the engine and drivetrain to handle extreme power.

Key Modifications:

- Engine Block: Sleeved block with billet main caps and girdles.

- Turbo System: Garrett GTX42R turbo with external wastegate.

- Internals: CP forged pistons, Carrillo rods, and ARP head studs.

- Fuel System: Dual fuel pumps with E85 compatibility.

- Transmission: Upgraded to a Tremec T-56 Magnum for durability.

Outcome:

- Produced 1,215 HP on E85 with a reliable, consistent performance at the drag strip.

- Required frequent maintenance and tuning adjustments to sustain high power levels.

Lesson: Extreme builds demand significant investment in reinforcements and regular maintenance to avoid failures.

Case Study 3: A Budget-Friendly 2JZ-GE NA-T Conversion

Overview:

- Goal: Achieve 400 HP on a tight budget using a naturally aspirated 2JZ-GE as the base.

- Vehicle: Lexus IS300.

- Challenges: Converting a naturally aspirated engine for forced induction on a limited budget.

Key Solutions:

- Turbo Setup: Used a budget-friendly eBay turbo kit with a smaller compressor for quick spool.

- Fuel Upgrades: Installed larger injectors and a piggyback ECU for fuel management.

- Internal Reinforcements: Retained stock pistons and rods but kept boost levels conservative (~8 psi).

Outcome:

- Achieved 385 HP reliably while staying within budget constraints.

- Highlighted the importance of tuning and conservative power goals for stock internals.

Lesson: A budget build can deliver satisfying results if you manage expectations and avoid pushing limits.

Common Themes from Case Studies

- Tuning is Key:

- Across all builds, professional tuning played a critical role in achieving reliability and performance.

- Matching Components to Goals:

- Builders who tailored parts to their specific objectives had the most success.

- Maintenance is Essential:

- Regular maintenance and inspections prevented catastrophic failures, especially in high-power builds.

How These Examples Can Inform Your Build

For Beginners:

- Focus on balanced, reliable builds with modest power goals.

- Use proven setups and consult experienced tuners.

For Advanced Builders:

- Plan for reinforcements and regular maintenance if pursuing high-horsepower builds.

- Prioritize quality over cost for critical components like turbos and internals.

Pro Tips from Experts

Expert Advice for a Successful 2JZ Build

Building a 2JZ engine is a rewarding journey, but it requires strategic planning and attention to detail. Here’s what seasoned professionals recommend to maximize your success.

Start with a Clear Plan

Expert Tip: “Define your goals upfront—are you building for street use, track racing, or maximum horsepower? The wrong parts or lack of planning will waste time and money.”

- Why it Matters: Every component decision, from turbo size to internals, should align with your intended use case.

- Pro Tip: Draft a build sheet to map out required parts, tools, and costs before starting.

Invest in Quality Components

Expert Tip: “Cutting corners on critical parts will cost you more in the long run.”

- Examples of Essential Investments:

- ARP head studs for high-boost reliability.

- Forged pistons and rods for builds exceeding 600 HP.

- High-performance gaskets to prevent leaks under stress.

- Pro Tip: Research trusted brands and avoid budget knockoffs that may fail under pressure.

Focus on Cooling and Heat Management

Expert Tip: “Heat is the enemy of performance and reliability—address it early in your build.”

- Critical Upgrades:

- Install an aluminum radiator and oversized intercooler to manage intake and engine temperatures.

- Use heat shielding and thermal coatings for components near the turbo and exhaust.

- Pro Tip: Monitor temperatures with sensors for oil, coolant, and exhaust gas to prevent overheating during high-performance use.

Don’t Skimp on Tuning

Expert Tip: “A great tune can make even a modest build exceptional, while a bad tune can ruin the best components.”

- Recommended Approach:

- Work with a tuner experienced in 2JZ engines.

- Use a standalone ECU for full control over ignition, fuel mapping, and boost levels.

- Pro Tip: Prioritize safety features like knock sensors, overboost protection, and AFR monitoring in your tuning setup.

Learn from Mistakes

Expert Tip: “Mistakes are inevitable in any build. What sets great builders apart is how they recover and learn.”

- Common Errors:

- Forgetting to double-check torque specs during assembly.

- Ignoring small leaks or noises that may indicate larger issues.

- Pro Tip: Document each step of your build to track progress and identify any problems early.

Stay Patient and Methodical

Expert Tip: “Rushing a build leads to shortcuts and errors—take your time to do it right.”

- How to Stay Methodical:

- Follow a step-by-step checklist during assembly and tuning.

- Triple-check critical areas like timing, gasket placement, and torque specs.

- Pro Tip: If in doubt, seek help from experts or consult detailed guides specific to 2JZ engines.

Join the Community

Expert Tip: “The 2JZ community is one of the most knowledgeable and supportive groups out there—don’t hesitate to ask for advice.”

- Where to Engage:

- Forums like Supra Forums and Lexus IS forums.

- Social media groups focused on Toyota performance builds.

- Pro Tip: Share your progress and seek feedback; others’ experiences can save you from making similar mistakes.

Keep Maintenance a Priority

Expert Tip: “Even the best-built engines need regular maintenance to stay reliable.”

- Maintenance Checklist:

- Regular oil changes with high-quality synthetic oils.

- Periodic checks of boost pressure, AFRs, and timing.

- Inspecting critical components like belts, hoses, and gaskets for wear.

- Pro Tip: Create a maintenance schedule tailored to your build’s power level and usage.

Final Words from the Experts

- “Building a 2JZ is as much about passion and patience as it is about power.”

- “Never stop learning—each build teaches you something new.”

Frequently Asked Questions About Building a 2JZ Engine

What makes the 2JZ engine so reliable?

The 2JZ engine’s reliability stems from its robust cast-iron block, forged crankshaft, and over-engineered internals. Designed to handle significant stress, the 2JZ can safely manage up to 800–1,000 HP with proper modifications and tuning.

How much horsepower can a stock 2JZ handle?

A stock 2JZ-GTE can reliably manage 600 HP on the factory internals when paired with proper tuning, upgraded fuel delivery, and cooling systems. Pushing beyond this threshold requires forged internals and additional reinforcements.

What’s the difference between a 2JZ-GTE and a 2JZ-GE?

The 2JZ-GTE features twin turbos, oil squirters, and a lower compression ratio for forced induction. The 2JZ-GE, while naturally aspirated, shares the same block but lacks the turbos and reinforcements, making it ideal for budget NA-T (naturally aspirated to turbocharged) conversions.

Is building a 2JZ engine expensive?

The cost varies based on goals:

- A basic rebuild may cost $3,000–$5,000.

- A moderate performance build (500–600 HP) could range from $10,000–$15,000.

- Extreme builds for 1,000+ HP can exceed $25,000, especially when including drivetrain and supporting mods.

What are the most common mistakes when building a 2JZ engine?

Common errors include:

- Failing to plan or budget adequately.

- Using mismatched components (e.g., oversized turbos for street builds).

- Skipping critical upgrades like ARP head studs or high-flow fuel pumps.

- Neglecting professional tuning and machining.

How do I choose the right turbo for my 2JZ?

Select a turbo based on your build’s goals:

- Street Builds: Focus on smaller turbos (58–62mm) for quick spool and drivability.

- Track Builds: Opt for larger turbos (70–76mm) for peak horsepower at higher RPMs.

- Consult your tuner or builder to match the turbo to your desired power output and driving habits.

What type of fuel is best for a 2JZ build?

The ideal fuel depends on power goals:

- Pump Gas: Suitable for builds under 500 HP.

- E85 (Ethanol): Popular for high-power setups due to its cooling properties and high octane rating.

- Race Fuel: Required for extreme builds exceeding 1,000 HP.

How important is tuning for a 2JZ engine?

Tuning is critical for optimizing performance, preventing detonation, and ensuring longevity. A proper tune adjusts air-fuel ratios, ignition timing, and boost levels to align with your modifications and goals.

Do I need forged internals for my 2JZ build?

Forged internals are recommended for builds exceeding 600 HP. Stock internals are durable but may fail under extreme boost or RPMs. Common upgrades include forged pistons, rods, and upgraded bearings.

Can I convert a 2JZ-GE to a 2JZ-GTE?

Yes, a GE-to-GTE conversion is common, especially for budget builds. Essential upgrades include:

- Adding a turbocharger (custom manifold and intercooler required).

- Lowering the compression ratio with thicker head gaskets.

- Upgrading the fuel and cooling systems.

How do I avoid overheating in a high-performance 2JZ?

Overheating can be avoided with:

- A high-capacity aluminum radiator.

- Larger intercoolers for intake temperature management.

- Proper tuning to avoid excessive timing advance.

What is the break-in procedure for a freshly built 2JZ engine?

Key steps include:

- Use a high-zinc break-in oil for the first 500–1,000 miles.

- Avoid sustained RPMs; vary engine speed frequently.

- Perform an early oil and filter change (after 50–100 miles) to remove debris from initial wear.

What are ARP head studs, and why are they important?

ARP head studs provide stronger clamping force than factory bolts, preventing head gasket failure under high boost. They are essential for any turbocharged or high-performance build.

What’s the most reliable ECU for a 2JZ?

Standalone ECUs like Haltech Elite, AEM Infinity, or Link G4+ are highly recommended. They offer precise control over fuel, ignition, and boost, ensuring reliability in modified setups.

How do I find a good tuner for my 2JZ build?

Look for tuners with:

- Proven experience with 2JZ engines.

- Access to modern dyno equipment.

- Positive reviews from the community (check forums and social media).

Closing Tips

- Patience Pays Off: Rushing a build often leads to costly mistakes. Take your time to plan, execute, and test thoroughly.

- Documentation is Key: Keep records of every modification, torque spec, and maintenance schedule.

- Community Support: Engage with the 2JZ community on forums and social platforms for advice, troubleshooting, and inspiration.

- Stay Proactive: Regular maintenance and performance checks ensure your build remains reliable and enjoyable.

Conclusion

Building a 2JZ engine is both an art and a science, offering enthusiasts an opportunity to create something truly remarkable. Whether your goal is to build a reliable daily driver, a high-performance track monster, or a show-stopping masterpiece, the key to success lies in meticulous planning, selecting quality components, and avoiding common mistakes.

Key Takeaways:

- Start with a clear and realistic goal that aligns with your budget and intended use.

- Research every component for compatibility and ensure they meet your performance needs.

- Invest in professional services for machining, assembly, and tuning to achieve optimal reliability and power.

- Engage with the 2JZ community to share experiences, seek advice, and stay updated on the latest advancements.

By following this guide and learning from the successes and challenges of others, you can avoid common pitfalls and ensure your 2JZ build is a source of pride, performance, and reliability for years to come.

Have questions or want to share your own 2JZ build experience? Comment below or reach out to join the conversation! Let’s keep the 2JZ legacy alive together.