When it comes to pushing the legendary 2JZ engine beyond its stock limits, the engine block is the foundation that can make or break your build. Think of it like the frame of a house; no matter how fancy the interior is, if the frame can’t hold up, everything else falls apart. The 2JZ block, while robust from the factory, wasn’t originally designed for the insane horsepower numbers some racers and tuners demand today. So, what does it take to beef it up? The answer lies in understanding the block’s weak points and reinforcing them smartly.

Many enthusiasts get caught up chasing big power numbers without realizing that the stock block has its limits. It’s like asking a family sedan to handle off-road racing—it can do it for a while, but eventually, something’s going to give. The stock 2JZ block can handle a decent amount of power, but once you start flirting with extreme boost or high RPMs, the metal can flex, crack, or wear prematurely. That’s why builders upgrade key components and add reinforcements to keep everything tight and reliable.

Upgrading the block isn’t just about slapping on stronger parts; it’s about creating a more rigid and durable structure that can withstand the brutal forces inside. For example, replacing the main caps with stronger versions or adding billet girdles drastically improves how the block resists twisting and bending. It’s like adding steel beams to that house frame—suddenly, it can handle a lot more stress without breaking a sweat.

In my own experience working on boosted 2JZ builds, I’ve seen firsthand how a reinforced block can be a game-saver. One engine I built was pushing over 1,000 horsepower, and without those upgrades, the block would have shown cracks or failed bearings within months. Instead, it ran strong, even under the harshest conditions. It’s proof that investing in the block’s strength pays off in reliability and peace of mind.

At the end of the day, building a stronger 2JZ block means respecting the physics at play. You’re dealing with forces that can twist metal and shatter parts if you’re not prepared. So, whether you’re aiming for a street monster or a track beast, reinforcing your 2JZ block is the first step to making sure your engine not only hits big numbers but lives to tell the tale.

How Much Power Can a Stock 2JZ Block Handle?

Ever wondered just how much muscle a stock 2JZ engine block can flex before it throws in the towel? It’s a question that pops up a lot, especially among those diving into high-performance builds. The truth is, the 2JZ block is no ordinary cast iron shell; it’s a beast known for its remarkable strength and resilience. But like anything, it has its limits.

In its factory form, the 2JZ block can comfortably handle around 600 to 700 horsepower without any internal reinforcements. That’s pretty impressive considering it was originally designed for a naturally aspirated setup with moderate power output. But push beyond that, and the block starts to feel the strain. Cracks can form, cylinder walls might flex, and the whole foundation risks failure under extreme boost or high RPM.

Think of the stock block like a sturdy bridge built for regular traffic. It can handle heavy loads, but slam a convoy of monster trucks over it constantly, and eventually, it’s going to show signs of wear. This is why many enthusiasts aiming for big power—say, north of 700 horsepower—start looking at upgrades or aftermarket blocks.

Another factor to consider is the quality of the factory casting and the condition of the block itself. A well-maintained, clean 2JZ block with no previous damage can sometimes stretch a bit further than average. But don’t bet the farm on it. When you’re chasing power levels above 800 or 900 horsepower, relying on the stock block alone is a gamble. It’s like walking a tightrope without a net.

So, what happens if you ignore these limits? You risk catastrophic engine failure, which can be costly and frustrating. That’s why serious builders often reinforce the block with upgrades like billet main caps or switch to a more robust aftermarket block designed to withstand extreme power levels.

In summary, the stock 2JZ block is a solid foundation for moderate to high horsepower builds, but it’s not invincible. For those pushing the envelope, understanding its limits is crucial to avoid unexpected breakdowns and keep your build running strong.

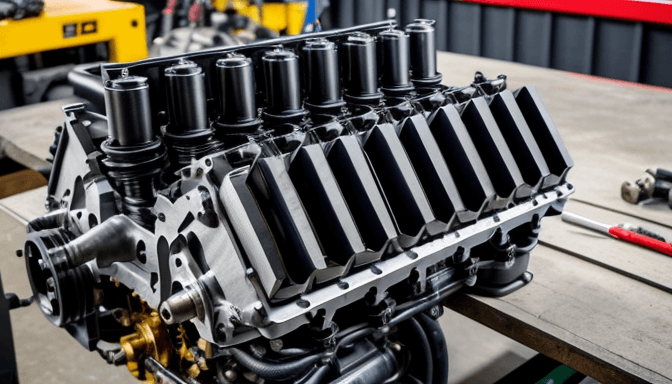

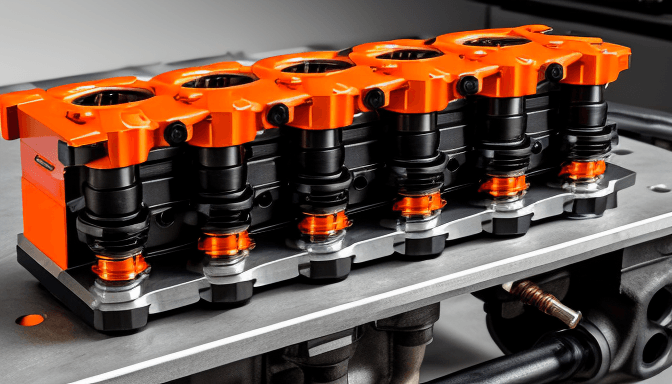

Upgrading Main Caps and Using Billet Girdles

When you’re pushing a 2JZ engine beyond its comfort zone, the stock main caps often become the weak link. Think of the main caps as the backbone holding your crankshaft in place. If they flex or shift under pressure, it’s like trying to run a marathon with a sprained ankle—disaster waiting to happen. Upgrading to stronger main caps isn’t just a luxury; it’s a necessity for high horsepower builds. These upgraded caps are usually made from tougher materials and offer a tighter, more secure fit around the crankshaft journals, drastically reducing the chance of flex or movement.

Now, let’s talk about billet girdles. Imagine the girdle as a cage that locks all the main caps together, distributing the enormous forces generated by high RPMs and boost evenly across the block. Without this reinforcement, your engine block can twist or warp, leading to catastrophic failure. Billet girdles are precision-machined from solid blocks of metal, offering superior rigidity compared to stock stamped steel or cast iron pieces. They act like a steel corset, keeping everything perfectly aligned no matter how hard you push the engine.

Upgrading both main caps and adding a billet girdle creates a synergy that significantly enhances block stiffness. This is crucial when running extreme horsepower levels, especially in drag racing or high-boost turbo setups. You’ll notice less crankshaft flex, reduced bearing wear, and improved overall engine reliability. It’s like giving your engine a suit of armor tailored to withstand the brutal forces inside.

Some builders might overlook these upgrades, thinking the stock parts will hold up just fine. But trust me, once you hit the 700-800 horsepower mark and beyond, the stock main caps can start to show their limits. The last thing you want is a cracked block or a spun bearing because you tried to save a few bucks early on. Investing in billet main caps and girdles pays off in the long run by preventing expensive engine damage.

In short, if you’re serious about building a 2JZ that can handle big power without breaking a sweat, upgrading your main caps and installing a billet girdle isn’t optional—it’s essential. It’s the foundation that keeps your engine strong and ready to perform at its best, lap after lap, run after run.

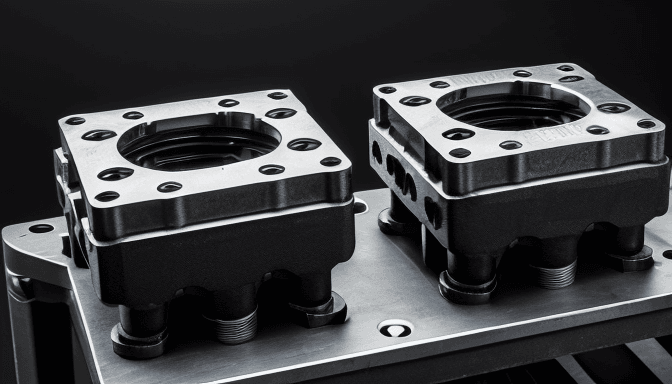

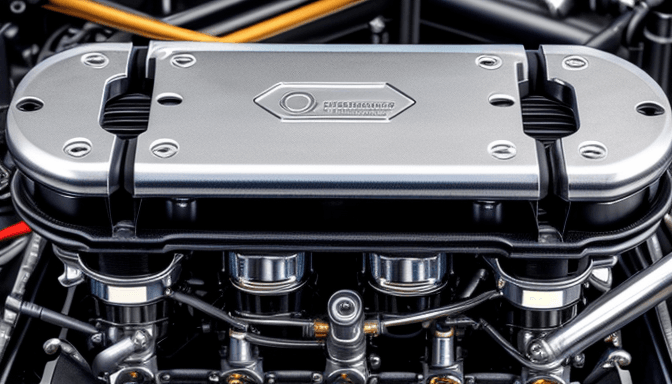

Dart Iron Eagle vs OEM Cast Block: What’s the Difference?

When it comes to building a high-horsepower 2JZ engine, the choice between the Dart Iron Eagle block and the OEM cast block can feel like picking between a trusty old friend and a powerful new contender. Both have their place, but they’re built for very different levels of abuse and performance. The OEM block, straight from Toyota’s factory, is a solid piece of engineering. It’s cast iron, known for its durability and ability to handle decent power levels without breaking a sweat. But, like a seasoned runner hitting their limit, it starts showing cracks—literally—when pushed beyond its comfort zone, especially in the realm of extreme horsepower.

Enter the Dart Iron Eagle block, a beast designed with one goal in mind: to withstand the kind of power that makes stock blocks beg for mercy. Unlike the OEM block, the Dart is made from ductile iron, which offers better strength and flexibility under stress. Think of it as upgrading from a sturdy wooden bridge to a reinforced steel one. This block is thicker, beefier, and engineered to resist the intense pressures of boosted, high-RPM engines without warping or cracking.

One of the biggest differences lies in the engineering details. The Dart block features extra material around critical areas like the main bearing saddles and cylinder bores. This means it can handle larger bore sizes and higher cylinder pressures without compromising integrity. Plus, it often comes with priority main oiling, ensuring the crankshaft and bearings get the lubrication they desperately need during those redline moments.

Another key factor is the design for aftermarket support. The Dart Iron Eagle is built with performance in mind, offering compatibility with a wide range of upgraded internals and accessories. It’s like a blank canvas for engine builders who want to push past the 1000-horsepower mark without worrying about the block giving out. Meanwhile, the OEM block is better suited for builds that stay closer to stock or moderately boosted levels.

Here’s a quick comparison table to highlight the main points:

| Feature | OEM Cast 2JZ Block | Dart Iron Eagle Block |

|---|---|---|

| Material | Cast Iron | Ductile Iron |

| Strength | Good for stock to moderate power | Excellent for extreme horsepower |

| Thickness | Standard | Increased wall thickness |

| Main Bearing Support | OEM design | Reinforced, priority oiling |

| Bore Capacity | Limited by casting | Supports larger bores |

| Price | More affordable | Premium cost |

In short, if you’re building a daily driver or a mildly tuned race engine, the OEM block might just do the trick. But if your goal is to push the 2JZ to its absolute limits—think insane boost levels and sky-high RPMs—the Dart Iron Eagle block is the no-nonsense choice. It’s built to endure, engineered to perform, and ready to handle the kind of power that makes legends.

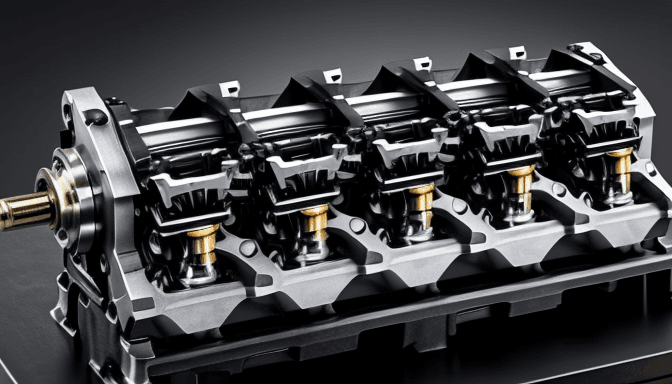

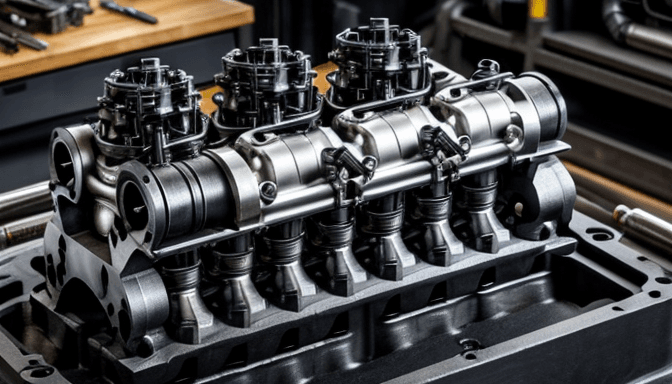

Best Forged Pistons, Rods, and Crankshafts for Big Power

When you’re pushing a 2JZ engine beyond its comfort zone, stock internals just won’t cut it. Think of the pistons, rods, and crankshaft as the heart and bones of your engine. If these parts aren’t tough enough, your build won’t last long under extreme horsepower. Forged components are the go-to choice because they offer superior strength and durability compared to cast parts. But not all forged parts are created equal, and picking the right ones can make or break your project.

Let’s start with pistons. Forged pistons are designed to withstand intense heat and pressure without cracking or deforming. Brands like Wiseco and JE Pistons have earned their reputation by delivering parts that handle big boost and high RPM like champs. These pistons often come with reinforced skirts and coatings that reduce friction and wear, which is crucial when you’re revving hard and pushing limits. Imagine them as the tough boots your engine wears to march through a battlefield of combustion forces.

Next up, connecting rods. The rods transfer all that explosive energy from the pistons to the crankshaft. Forged rods made from 4340 steel or similar alloys are the best bet here. They resist bending and stretching, which means your engine stays tight and responsive even at sky-high horsepower levels. Companies like Carrillo and Manley are popular among 2JZ builders because their rods strike a great balance between strength and weight. Too heavy, and you lose rev speed; too light, and you risk failure. It’s like choosing the right gear for a mountain climb—too heavy slows you down, too light and you lose grip.

Then, the crankshaft. This is the backbone of your engine’s rotating assembly. Forged crankshafts endure brutal stress, especially in turbocharged setups where torque spikes can be relentless. A forged billet crankshaft is usually the safest route for builds aiming beyond 1000 horsepower. They’re machined from a single piece of high-grade steel, offering excellent resistance to twisting and fatigue. Whether you’re upgrading from OEM or going aftermarket, investing in a quality forged crankshaft is non-negotiable for reliability.

To sum it up, your best bet for big power 2JZ builds is to combine high-quality forged pistons, rods, and crankshafts that complement each other. These parts don’t just survive—they thrive under pressure. Remember, the goal isn’t just to make power but to keep it consistent and safe. After all, what good is horsepower if your engine can’t handle it?

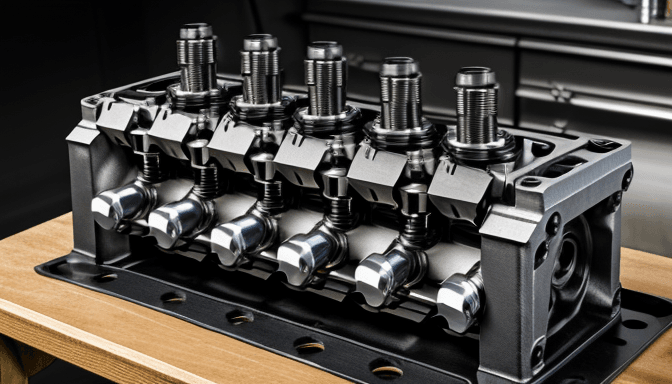

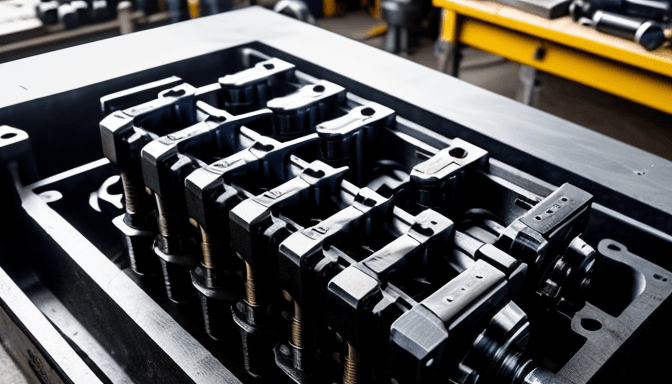

Block Reinforcement: Sleeves, Studs, and O-Ringing

When pushing a 2JZ engine beyond its stock limits, the block itself often becomes the weak link. Imagine trying to hold a stack of books with rubber bands instead of a solid strap — that’s what happens if you don’t reinforce the block properly. **Sleeves, studs, and O-ringing** are the unsung heroes that keep everything tight and secure under extreme stress.

First up, **cylinder sleeves**. These are like armor for your cylinders, providing an extra layer of strength and wear resistance. Stock blocks can crack or warp when you crank up the boost and RPM, but sleeves help maintain the cylinder’s integrity. They’re especially crucial if you’re increasing displacement or running high boost levels. Think of sleeves as a protective shield that prevents the block from giving up under pressure.

Next, **head studs** replace the stock head bolts to clamp the cylinder head down with much greater force. Stock bolts can stretch or fail when the engine is subjected to extreme combustion pressures, leading to head gasket leaks or worse. Upgrading to high-quality studs ensures the head stays firmly seated, preventing leaks and maintaining compression. It’s like switching from flimsy nails to heavy-duty screws when building a deck — the difference in strength is night and day.

Then there’s **O-ringing**, a technique that involves machining a groove around the cylinder bore and installing a rubber or metal ring to seal the combustion chamber. This prevents head gasket failure by improving the seal between the block and head. If you’ve ever dealt with blown head gaskets on a boosted engine, you know how frustrating it can be. O-ringing is a smart way to avoid that headache, especially when running high boost or nitrous.

These reinforcements don’t work in isolation; they complement each other to create a bulletproof block. For example, sleeves protect the bore, studs hold the head tight, and O-rings seal the combustion chamber perfectly. Together, they form a fortress around your engine’s most vulnerable points.

Here’s a quick rundown of what each reinforcement targets:

| Reinforcement | Purpose | Benefit |

|---|---|---|

| Cylinder Sleeves | Protect bore from wear and cracking | Improved durability under high boost and displacement |

| Head Studs | Clamp head to block securely | Prevents gasket leaks and head lift |

| O-Ringing | Seal combustion chamber | Enhanced head gasket reliability |

In my experience, skipping these upgrades is like building a house on sand. You might get away with it for a while, but eventually, things will fall apart. If you’re serious about pushing your 2JZ to the edge, investing in these block reinforcements is non-negotiable. They’re the foundation that lets you chase big power without the constant fear of catastrophic failure.

Oiling System Mods for High-RPM Reliability

When you push a 2JZ engine beyond its comfort zone, especially at high RPMs, the oiling system becomes your unsung hero. Think of it as the engine’s lifeblood—without proper lubrication, parts wear out fast, heat builds up, and disaster is just around the corner. Stock oil pumps and passages are designed for everyday driving, not the brutal demands of racing or high-boost setups. So, what’s the fix? Upgrading the oiling system isn’t just a good idea; it’s a must.

First off, consider swapping the stock oil pump for a high-volume or high-pressure version. This upgrade ensures that every bearing, cam lobe, and piston pin gets a steady stream of oil, even when the engine is screaming at 8,000 RPM or more. It’s like upgrading from a garden hose to a firehose—more flow means better cooling and lubrication under stress.

But volume isn’t everything. The oil passages themselves can become bottlenecks. Enlarging these passages or polishing them smooth can reduce resistance and improve flow. In some high-horsepower builds, fabricators even install external oil lines or remote oil filters to keep oil temperatures in check and improve filtration. Cooler oil means longer engine life, plain and simple.

Another trick is to add an oil cooler or upgrade the existing one. When you’re running high boost and RPMs, oil temperatures can spike quickly, thinning the oil and reducing its protective qualities. An efficient cooler keeps oil viscosity stable, like a thermostat for your engine’s lifeblood, preventing it from getting too hot or too thin.

Don’t overlook the importance of quality oil and frequent changes. Synthetic oils with high zinc content offer better film strength and wear protection, especially under extreme conditions. Pair that with a robust filtration system, and you’ve got a recipe for reliability.

Finally, some builders go the extra mile by installing an oil accumulator or a dry sump system. These setups ensure that oil pressure never drops during hard cornering or rapid acceleration, where the oil might otherwise slosh away from the pickup. It’s a small detail that makes a huge difference when the engine’s under full attack.

In essence, upgrading the 2JZ’s oiling system for high-RPM reliability isn’t just about throwing parts at the problem. It’s about understanding how oil moves, cools, and protects—and then tweaking every step of that process. When done right, these mods transform the 2JZ from a strong engine into a bulletproof powerhouse that can take the heat and keep on running.

Bore and Stroke Considerations for 3.0L vs 3.4L vs 3.5L Builds

When it comes to building a 2JZ engine, the choice between a 3.0L, 3.4L, or 3.5L displacement isn’t just about numbers—it’s about how you want your engine to perform and respond. Think of bore and stroke like the engine’s heartbeat and lungs. The bore is the diameter of the cylinder, while the stroke is how far the piston travels up and down. Changing these changes the engine’s character drastically.

Starting with the 3.0L build, this usually means sticking close to the stock bore and stroke dimensions. It’s a safe bet if you want a reliable, high-revving engine that’s easier to tune and maintain. The smaller displacement means the engine breathes well at higher RPMs, making it feel lively and responsive. But if you’re chasing big torque and raw power, 3.0L might leave you wanting more.

Now, bumping up to 3.4L involves increasing either bore, stroke, or both. This gives you a nice balance—more displacement means more torque and power down low, which is great for street and drag applications. However, the trade-off is often a bit less top-end revving ability. The engine becomes more like a heavyweight boxer—powerful and steady, but not quite as quick on its feet.

Then there’s the 3.5L build, which pushes the limits of the 2JZ architecture. This usually means a significantly longer stroke combined with a larger bore. The result? Massive torque and horsepower potential, but with a few caveats. You’ll need to consider stronger internals and upgraded components because the stress on the block and rotating assembly ramps up. Think of it as turning your engine into a beast that needs serious care and attention.

Here’s a quick look at how bore and stroke affect these builds:

| Displacement | Bore | Stroke | Performance Traits |

|---|---|---|---|

| 3.0L | Stock or slightly overbored | Stock (86mm) | High revving, responsive, less torque |

| 3.4L | Overbored | Increased stroke (~94mm) | Balanced torque and power, good street performance |

| 3.5L | Significantly overbored | Long stroke (~97mm+) | High torque, big power, requires stronger internals |

Choosing the right combination depends on your goals. Want an engine that screams at high RPM? Stick closer to 3.0L. Need grunt and torque for drag racing or heavy turbo setups? 3.4L or 3.5L might be your playground. Just remember: increasing bore and stroke isn’t free. It demands upgrades to the block, pistons, rods, and more. Otherwise, you risk running into reliability issues down the line.

In my experience, dialing in the perfect bore and stroke combo is like tuning a musical instrument. Too tight or too loose, and the harmony is off. But when you get it right? The engine sings, delivering power exactly where and when you want it. So, take your time, weigh your options, and build with both passion and precision.

Choosing the Right Bearings and Clearances

When it comes to building a high-horsepower 2JZ engine, picking the right bearings and setting the correct clearances isn’t just a minor detail — it’s a cornerstone of reliability. Imagine the crankshaft spinning at thousands of RPMs, under insane pressure. Now, think about what happens if those bearings aren’t up to the task. The engine can seize, bearings can fail, and your dream build turns into a nightmare. So, how do you avoid this? It all starts with understanding the delicate balance between tightness and looseness in your bearing clearances.

Bearing materials play a huge role here. Stock bearings are fine for everyday driving, but once you push past 600+ horsepower, you need something tougher. Look for bearings made from tri-metal or even coated with materials like molybdenum or copper-lead. These coatings reduce friction and improve wear resistance, which is crucial when the engine is operating under extreme loads and heat.

Clearances might sound like a small number, but they’re a big deal. Too tight, and the oil film can’t form properly, causing metal-to-metal contact. Too loose, and you risk oil pressure drops and bearing slap. The sweet spot depends on your power goals and the type of oil you’re running. A typical range for a heavily built 2JZ might be around 0.0015” to 0.0020” clearance on the mains and rods, but this can vary.

Here’s a quick look at what to consider when choosing bearings and clearances:

- Power level: Higher horsepower means you need stronger bearings and sometimes larger clearances.

- RPM range: High RPM engines require clearances that allow for thermal expansion without compromising oil pressure.

- Oil type: Thicker oils need slightly larger clearances; synthetic oils can handle tighter clearances.

- Engine use: Daily drivers might tolerate tighter clearances, while race engines need room for extreme conditions.

Think of it like a dance — the crankshaft and bearings need just enough room to move smoothly, cushioned by a thin layer of oil, but not so much that they lose contact or oil pressure. I remember working on a 2JZ build where incorrect bearing clearances caused early bearing wear, leading to a costly rebuild. After switching to properly sized tri-metal bearings and adjusting clearances, the engine ran flawlessly, even at 900 horsepower.

In the end, this isn’t a place to cut corners. Taking the time to select the right bearings and get those clearances dialed in will pay off with an engine that can handle big power without drama. It’s all about precision — because when you’re chasing extreme horsepower, every thousandth of an inch counts.

Engine Assembly Tips for 1000–2000+ HP Setups

Building a 2JZ engine that can handle between 1000 and 2000+ horsepower is no small feat. It’s like preparing a marathon runner for an ultra race—you need every part to work perfectly, and the assembly process must be flawless. One tiny mistake can lead to catastrophic failure, so precision is everything here. When assembling such a powerhouse, the first rule is to never rush. Take your time, double-check measurements, and make sure every component fits like a glove. Remember, this isn’t just about putting parts together; it’s about creating a bulletproof machine.

Start by focusing on the block itself. Even if you’ve upgraded to a Dart Iron Eagle or reinforced the OEM block, cleanliness is key. Any dirt or debris can cause scoring or premature wear. Use a clean workspace and high-quality assembly lube liberally—this stuff is the lifeblood during those first critical moments after startup. It’s also crucial to torque bolts in the correct sequence and to the manufacturer’s specs. Over-tightening or uneven torque can warp the block or crankshaft, which is a disaster waiting to happen.

When it comes to the rotating assembly—your forged pistons, rods, and crankshaft—clearances must be spot on. Too tight, and you risk seizure; too loose, and you invite knock and wear. This balance is like tuning a fine instrument. I’ve seen engines fail because someone ignored bearing clearance specs or skipped the step of measuring crankshaft journal diameters carefully. Use a micrometer and plastigauge to verify clearances during assembly. It’s tedious, but worth every second.

Another often overlooked detail is the installation of head studs and O-rings. For a 1000+ HP setup, the stock head bolts won’t cut it. Head studs provide consistent clamping force, reducing the risk of head gasket failure under insane boost pressures. O-ringing the block around the cylinders adds an extra layer of security to keep combustion pressures sealed tight. Think of it as putting a seatbelt and airbags in your engine—extra protection when things get wild.

Don’t forget the oiling system. Upgraded oil pumps, baffled pans, and high-flow oiling passages are essential to keep everything lubricated and cool. High RPMs and extreme loads generate heat and stress like nothing else. I always recommend dry sump systems for builds pushing beyond 1500 HP, but even a well-planned wet sump setup can hold its own if done right.

Finally, patience and attention to detail during assembly pay off big time. It’s tempting to rush and get the engine running, but trust me, slow and steady wins this race. Check and recheck every measurement, torque spec, and fitment. When you hear that engine roar to life and see those power numbers climb, you’ll know that every painstaking step was worth it.

Frequently Asked Questions

- How much horsepower can a stock 2JZ engine block handle?Great question! The stock 2JZ block is famously robust, typically handling around 600 to 700 horsepower reliably. Beyond that, you’re flirting with risk unless you reinforce or upgrade key components. Think of it like a sturdy bridge—it can hold a lot, but pushing too much weight without reinforcements can cause cracks.

- Why should I upgrade main caps and use billet girdles?Upgrading main caps and installing billet girdles are game-changers for block rigidity. These upgrades prevent crankshaft flex and reduce block distortion under extreme power and high RPM. Imagine adding steel beams to a building to keep it from swaying during a storm—that’s what these parts do for your engine block.

- What’s the difference between the Dart Iron Eagle block and the OEM cast 2JZ block?The Dart Iron Eagle block is like the heavyweight champion of engine blocks—made from high-strength iron with thicker walls and improved features for extreme builds. In contrast, the OEM cast block is lighter and great for moderate power but may struggle under ultra-high horsepower stress.

- Which forged pistons and rods are best for high horsepower 2JZ builds?Forged components from brands like CP, Wiseco, and Manley are top picks. They provide exceptional strength and durability to withstand the explosive forces inside a high-boost 2JZ. Think of forged pistons and rods as the armor that protects your engine’s heart during battle.

- What block reinforcement methods are essential for extreme boost levels?Key reinforcements include cylinder sleeves, upgraded head studs, and O-ringing the block. These techniques seal and strengthen the block to prevent cylinder wall failure and head gasket leaks under massive boost and high RPMs. It’s like wrapping your engine in a protective shield.

- How important are oiling system upgrades for high-RPM reliability?Super important! High RPM and horsepower increase oil demands drastically. Upgrading oil pumps, adding baffled oil pans, and improving oil cooling keep lubrication consistent, preventing catastrophic failures. Think of it as ensuring your engine’s lifeblood keeps flowing smoothly under pressure.

- Should I choose a 3.0L, 3.4L, or 3.5L displacement for my build?Each displacement has its perks: 3.0L for high revving and responsiveness, 3.4L for a balanced power and torque combo, and 3.5L for maximum torque and big power potential. It’s like picking the right gear for your race—choose based on your power goals and driving style.

- Why are bearing selection and clearances critical in high-power 2JZ engines?Proper bearings and clearances ensure longevity and performance by reducing friction and handling extreme loads. Using the wrong materials or tight clearances can cause premature wear or seizure. It’s like choosing the right shoes for a marathon—comfort and durability matter!

- What are some expert tips for assembling a 1000+ horsepower 2JZ engine?Precision is king! Use torque specs religiously, check clearances multiple times, and ensure component compatibility. Don’t rush—think of engine assembly like crafting a fine watch; every tiny detail counts for reliability at insane power levels.