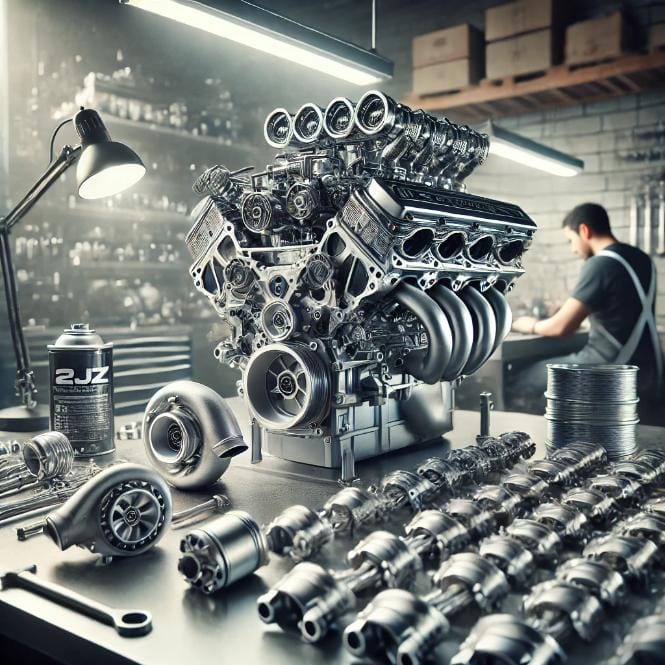

The Legend of the 2JZ Engine in Drifting

When it comes to drifting, few engines have achieved the iconic status of the Toyota 2JZ. Revered for its unparalleled reliability, high torque output, and exceptional tuning potential, the 2JZ has become the go-to powerplant for drift enthusiasts worldwide. This legendary inline-six engine first debuted in the early 1990s, making its mark in the Toyota Supra, a car synonymous with performance and precision.

The 2JZ’s robustness lies in its iron block construction, capable of withstanding immense stress, and its seamless power delivery, which is crucial for controlled drifts. Whether you’re building a weekend warrior or a competition-level drift car, this guide will equip you with the knowledge to optimize your 2JZ for torque, responsiveness, and durability.

What You’ll Learn in This Guide

- A step-by-step breakdown of building a drift-specific 2JZ engine.

- Key upgrades to enhance torque and high-stress reliability.

- How to optimize cooling, fuel, and induction systems for peak performance.

This comprehensive guide combines insights from experts and enthusiasts, ensuring you have a roadmap to craft a 2JZ engine that dominates on the track.

Understanding the Basics of the 2JZ Engine

Overview of 2JZ Variants

The 2JZ family includes two main variants:

- 2JZ-GTE (Twin Turbocharged): Known for its forced induction system, the GTE is favored for its immense power potential. With upgrades, it can handle over 1,000 horsepower, making it perfect for high-stakes drifting.

- 2JZ-GE (Naturally Aspirated): While not as powerful in stock form, the GE provides a solid foundation for budget builds. With the right modifications, it can rival its turbocharged sibling.

Key Features of the 2JZ Engine

- Iron Block Durability: Resists warping under extreme heat and stress.

- Inline-Six Configuration: Smooth power delivery and minimal vibration.

- Dual Overhead Camshaft (DOHC): Ensures precise valve timing, essential for high-revving applications.

- High Aftermarket Support: Access to a vast array of performance parts for customization.

Why the 2JZ is Perfect for Drift Cars

Drifting demands consistent torque and responsiveness, qualities that the 2JZ excels at. The engine’s ability to sustain high RPMs without failure is another advantage, enabling drivers to execute prolonged slides without compromising performance. Additionally, its robust design allows for extensive tuning, ensuring it can be tailored to any drift setup.

Planning Your Build: Setting Goals and Budget

Building a 2JZ engine for drift applications requires a clear vision of your performance goals and an understanding of the associated costs. Whether you’re aiming for competitive drifting or recreational use, planning is critical to ensuring a successful and reliable build.

Defining Your Performance Goals

Before you start sourcing parts, consider the following:

- Target Horsepower and Torque:

- For entry-level drifting, 400–600 HP provides a good balance between power and control.

- For competitive drifting, aim for 700+ HP with a focus on high torque for quick throttle response.

- Drift Style:

- Do you prefer technical, low-speed tracks or high-speed, wide-angle slides? This impacts turbo selection, suspension setup, and more.

- Reliability vs. Power:

- Aggressive power outputs demand more frequent maintenance. Striking a balance ensures longevity.

Budgeting for Your Build

A 2JZ drift engine build can range significantly in cost depending on your goals:

- Core Engine Costs:

- Rebuilding a stock 2JZ-GE engine: $3,000–$5,000.

- Modifying a 2JZ-GTE for performance: $10,000–$50,000.

- Aftermarket Components:

- High-performance pistons and rods: $1,500–$2,500.

- Turbocharger (e.g., GTX3076R): $1,000–$3,000.

- Fuel system upgrades (injectors, pumps): $1,000–$2,000.

- Labor and Tuning:

- Professional tuning: $500–$1,500.

- Machining services (e.g., cylinder head work): $500–$2,000.

Planning Your Timeline

Rushing through a build often leads to mistakes. Plan for:

- Research and parts sourcing: 2–4 weeks.

- Disassembly and inspection: 1–2 weeks.

- Build and assembly: 3–5 weeks, depending on complexity.

Setting a Realistic Scope

While it’s tempting to aim for an extreme build, consider your experience and resources. Start with a manageable setup and leave room for upgrades as you progress.

Common Planning Mistakes to Avoid

- Underestimating costs: Always budget for 10–20% over your initial estimate.

- Overcomplicating the build: Focus on reliability for beginner and intermediate drift builds.

- Ignoring professional help: Seek expert advice for tuning and component compatibility.

Essential Tools and Preparations for the Build

A well-prepared workspace and the right tools are critical for successfully building a 2JZ engine. Proper preparation minimizes errors and ensures a smoother assembly process.

Tools You’ll Need

Here’s a checklist of essential tools for your 2JZ engine build:

- Basic Hand Tools:

- Ratchets, sockets, and wrenches (metric sizes).

- Screwdrivers, pliers, and Allen keys.

- Specialized Engine Tools:

- Torque wrench: Ensures bolts are tightened to precise specifications.

- Piston ring compressor: For installing pistons into the cylinders.

- Engine stand: Provides stability and easy access during assembly.

- Valve spring compressor: For cylinder head work.

- Measurement Tools:

- Feeler gauges: For measuring clearances (e.g., valve lash).

- Dial indicator: To measure crankshaft end play.

- Micrometer and calipers: For precise measurements of engine components.

- Cleaning Supplies:

- Parts washer or solvent.

- Lint-free rags and brushes for thorough cleaning.

- Compressed air for removing debris.

Workspace Setup

A clean and organized workspace is just as important as the tools themselves. Here are some tips:

- Dedicated Workbench: Use a sturdy surface for assembling small components.

- Lighting: Install bright, adjustable lights to illuminate the workspace.

- Labeling System: Use labeled bags or containers to keep bolts and small parts organized.

- Safety Equipment:

- Gloves and safety goggles.

- Fire extinguisher for emergencies.

Preparations Before Disassembly

- Document Everything: Take photos of the engine before and during disassembly. These will serve as references during reassembly.

- Organize Components: Label parts and arrange them logically (e.g., by system: intake, exhaust, cooling).

- Inspect Tools: Ensure all tools are clean, calibrated, and ready for use.

Finding Reputable Parts Suppliers

Using quality parts is essential for durability and performance. Research and connect with trusted suppliers for components like:

- Forged pistons and rods.

- Performance camshafts and turbochargers.

- OEM or high-performance gaskets and seals.

Avoiding Common Mistakes

- Skipping Measurements: Always verify tolerances, even for new parts.

- Using Inadequate Tools: Avoid shortcuts with improper tools that may damage components.

- Overlooking Cleanliness: Any dirt or debris can cause premature wear or failure.

Step-by-Step Disassembly and Inspection of the Engine

Disassembling a 2JZ engine is a critical phase that lays the foundation for your build. A meticulous approach ensures you identify worn components and avoid issues during reassembly.

Step 1: Preparing for Disassembly

- Drain Fluids:

- Remove oil, coolant, and other fluids into appropriate containers.

- Properly dispose of fluids according to local regulations.

- Remove Accessories:

- Start by disconnecting the alternator, power steering pump, and A/C compressor.

- Label all bolts and components for easy reassembly.

- Organize Your Workspace:

- Use trays or labeled bags for bolts, gaskets, and other small parts.

Step 2: Cylinder Head Removal

- Intake and Exhaust Systems:

- Detach the intake manifold, throttle body, and exhaust manifold.

- Inspect for carbon buildup, cracks, or warping.

- Camshafts and Timing System:

- Remove the valve covers to access the camshafts.

- Carefully unbolt the camshaft caps in sequence to avoid damage.

- Mark timing components and remove the timing belt.

- Head Removal:

- Loosen the head bolts in a crisscross pattern to prevent warping.

- Lift the cylinder head and inspect for cracks or damage.

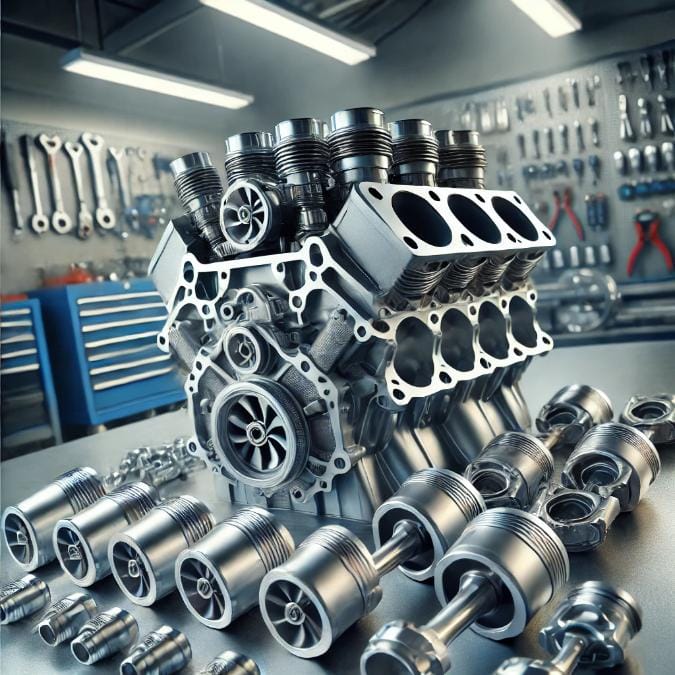

Step 3: Bottom-End Disassembly

- Oil Pan and Pump:

- Remove the oil pan to access the crankshaft and connecting rods.

- Inspect the oil pump for wear or damage.

- Pistons and Rods:

- Unbolt the connecting rod caps and push the pistons out carefully.

- Check for scoring on the cylinder walls or piston damage.

- Crankshaft Removal:

- Remove the main caps in the correct sequence.

- Inspect the crankshaft journals for wear or scoring.

Step 4: Thorough Inspection

- Block Inspection:

- Check for cracks or damage in the cylinder walls.

- Verify the deck surface is flat using a straight edge.

- Component Analysis:

- Measure piston-to-wall clearance and crankshaft endplay.

- Assess the condition of bearings, seals, and gaskets.

- Head Inspection:

- Check for valve seat wear, spring tension, and camshaft wear patterns.

Step 5: Cleaning and Preparation

- Clean Components:

- Use a parts washer or solvent to clean all components thoroughly.

- Remove carbon deposits and debris from intake and exhaust ports.

- Prepare for Machining:

- Mark areas needing machining (e.g., cylinder honing, head resurfacing).

- Transport components to a trusted machine shop if necessary.

Pro Tips for Disassembly

- Take detailed notes or videos for reassembly.

- Avoid using excessive force to prevent damaging components.

- Use high-quality tools to ensure accuracy during disassembly.

Upgrading the 2JZ for Drift Performance

To optimize the 2JZ engine for drifting, key upgrades focus on increasing durability, torque delivery, and responsiveness under high-stress conditions. Each component plays a vital role in achieving consistent performance on the track.

Pistons and Connecting Rods

Why Upgrade?

Stock components can handle moderate power, but forged pistons and rods are essential for high-horsepower builds to prevent catastrophic failure.

- Forged Pistons:

- Benefits: Increased strength, reduced risk of detonation damage.

- Popular Choices: CP Pistons, JE Pistons.

- Recommended Compression Ratio: 9:1 to balance power and reliability.

- Connecting Rods:

- Benefits: Enhanced durability for high-RPM drifting.

- Options: H-beam or I-beam rods (e.g., Manley, Carrillo).

- Consider lightweight options for quicker throttle response.

Crankshaft and Bearings

Upgrading the Crankshaft:

The stock 2JZ crankshaft is robust, but polishing or replacing it can provide added reliability under extreme conditions.

- Crankshaft Balancing:

- Ensures smoother operation and reduced vibration.

- Aftermarket Cranks:

- Ideal for builds exceeding 1,000 HP. Brands like BC or Tomei offer excellent options.

High-Performance Bearings:

- Material Selection:

- Tri-metal or bi-metal bearings for increased wear resistance.

- Clearance Optimization:

- Maintain proper oil clearance to prevent failure during prolonged drift sessions.

Fasteners and Gaskets

High-Strength Fasteners:

- ARP Head Studs: Prevent head gasket failures under boost.

- Main Stud Kits: Strengthen the bottom end for high-torque applications.

Metal Head Gaskets:

- Benefits: Better sealing under extreme conditions.

- Thickness Selection: Adjust based on compression ratio and boost levels.

Oil Pump and Pan Upgrades

Drifting involves prolonged lateral G-forces, making proper oiling critical.

- High-Flow Oil Pump:

- Ensures consistent oil pressure at high RPMs.

- Baffled Oil Pan:

- Prevents oil starvation during aggressive cornering.

- Recommended Brands: Moroso, Powerhouse Racing.

Harmonic Balancer

Upgrading to a performance harmonic balancer reduces vibration and prolongs the life of internal components.

- Options: Fluidampr or ATI Super Damper for maximum reliability.

Common Mistakes to Avoid

- Skimping on internal components, risking engine failure.

- Choosing the wrong compression ratio, which can impact drivability.

- Ignoring professional balancing for rotating assembly components.

Optimizing the Cylinder Head for Torque and Responsiveness

The cylinder head is a critical component in determining the engine’s airflow, power delivery, and responsiveness. Upgrading the cylinder head maximizes the 2JZ engine’s performance, making it more suitable for drifting, where torque and throttle control are vital.

Porting and Polishing

Improving airflow through the cylinder head is essential for maximizing power and efficiency.

- Porting:

- Enlarge and smooth intake and exhaust ports to reduce flow restrictions.

- Focus on consistency to balance airflow across all cylinders.

- Polishing:

- Smoothen the combustion chambers to prevent carbon buildup.

- Benefits: Increased airflow velocity and improved combustion.

Pro Tip: Work with a professional or invest in CNC porting for precision and consistency.

Upgrading Valves and Springs

Enhanced valves and springs ensure stability and durability at high RPMs.

- Valves:

- Use stainless steel or titanium valves for strength and lightweight performance.

- Oversized valves can improve airflow in high-power builds.

- Valve Springs:

- Install heavy-duty springs to prevent valve float at high RPMs.

- Recommended Brands: Supertech, Brian Crower.

Camshaft Selection

Choosing the right camshafts balances torque and high-RPM power.

- Performance Camshafts:

- Higher lift and duration increase airflow, improving overall performance.

- Options: Tomei PonCams for mild upgrades, or HKS for aggressive setups.

- Camshaft Timing:

- Adjustable cam gears allow fine-tuning for optimal torque and responsiveness.

- Benefits: Improved low-end torque for controlled drifts.

Valve Seats and Guides

- Upgraded Valve Seats:

- Durable materials like beryllium copper resist wear under extreme conditions.

- Valve Guides:

- Replace stock guides with bronze or brass for smoother operation.

Head Gasket and Decking

- Metal Head Gasket:

- Provides better sealing under high compression and boost.

- Adjust thickness to maintain desired compression ratio.

- Deck Resurfacing:

- Ensure the cylinder head and block surfaces are perfectly flat to prevent leaks.

Final Assembly and Testing

- Seal Installation:

- Use high-quality seals to prevent oil leaks.

- Pressure Testing:

- Verify the integrity of the cylinder head after modifications.

Common Mistakes to Avoid

- Mismatched camshafts and turbocharger setups, leading to poor performance.

- Neglecting spring seat pressure adjustments, causing valve float.

- Skipping proper testing, risking performance issues after assembly.

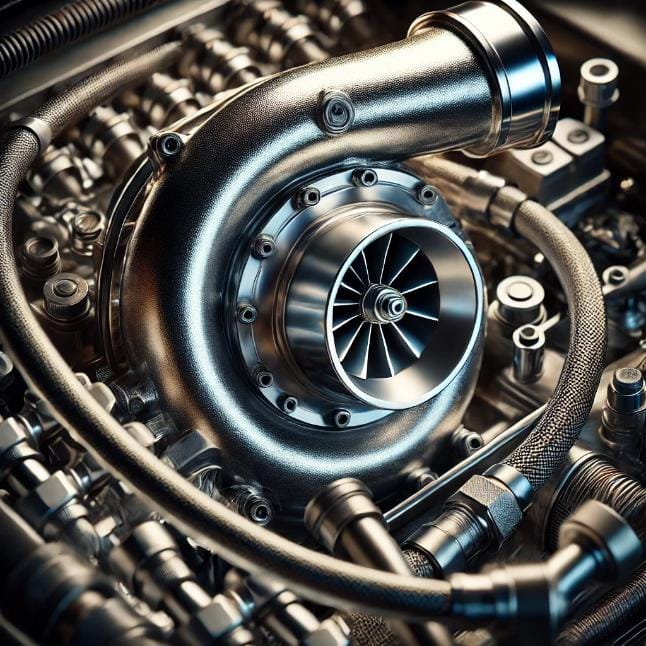

Choosing the Perfect Forced Induction System

A properly selected turbo setup is essential for optimizing the 2JZ engine’s torque, responsiveness, and power delivery for drift applications. The right choice depends on your performance goals, driving style, and budget.

Single vs. Twin-Turbo Setups

Understanding the pros and cons of single and twin-turbo setups helps in selecting the ideal system for your drift car.

- Single Turbo:

- Advantages:

- Simpler installation and maintenance.

- Potential for higher top-end power with larger turbos.

- Disadvantages:

- Increased turbo lag with larger units.

- Best For: Competitive drift builds prioritizing high horsepower.

- Advantages:

- Twin-Turbo:

- Advantages:

- Faster spool time with smaller turbos.

- Smoother power delivery.

- Disadvantages:

- More complex setup and higher costs.

- Best For: Balanced power and responsiveness for technical drifting.

- Advantages:

Turbocharger Sizing

Choosing the right turbo size ensures optimal power and responsiveness.

- Smaller Turbos:

- Faster spool time for quick throttle response.

- Ideal for technical, low-speed drifting.

- Larger Turbos:

- Higher top-end power for high-speed tracks.

- Trade-off: Increased lag.

Recommended Options:

- Garrett GTX3076R: Excellent balance of power and responsiveness.

- Precision 6266: High-performance option for competitive builds.

Quick Spool Valve (QSV)

A Quick Spool Valve enhances the performance of larger turbos by improving spool times, making it a popular addition for drift-specific setups.

Intercooler Selection and Placement

Efficient intercooling ensures the engine runs cooler and performs consistently under stress.

- Intercooler Core Size:

- Match the core size to your turbo’s airflow capacity.

- Avoid oversized cores, which may increase lag.

- Front-Mount Intercoolers (FMIC):

- Best for maximizing cooling efficiency.

- Ensure proper airflow and mounting to avoid overheating issues.

Wastegate and Blow-Off Valve (BOV)

- Wastegate:

- External wastegates provide precise boost control.

- Common Sizes: 38mm for mild builds, 44mm+ for high-boost applications.

- Blow-Off Valve:

- Prevents turbo surge by releasing excess pressure during gear changes.

- Recommended Brands: Tial, HKS.

Boost Controller and Tuning

- Boost Controllers:

- Electronic controllers allow for adjustable boost levels on the fly.

- Example: AEM Tru-Boost for easy tuning.

- Tuning Considerations:

- Optimize air-fuel ratios to prevent detonation.

- Focus on consistent boost delivery for drifting.

Common Mistakes to Avoid

- Selecting a turbo too large for your driving style, causing excessive lag.

- Overlooking proper intercooler sizing and placement, leading to heat soak.

- Using inadequate wastegate springs, causing inconsistent boost control.

Enhancing Fuel Delivery and Management Systems

A robust fuel system is critical for ensuring your 2JZ engine delivers consistent power under the demanding conditions of drifting. Proper upgrades and tuning prevent fuel starvation, optimize combustion, and support high-horsepower applications.

Fuel Injectors

Upgraded fuel injectors ensure sufficient fuel delivery for increased horsepower.

- Choosing the Right Size:

- Calculate injector size based on your target horsepower:

- 500 HP: ~550cc injectors.

- 700 HP: ~750cc injectors.

- 1,000 HP: 1,000cc or larger.

- Consider flow-matched injectors for balanced fuel distribution.

- Calculate injector size based on your target horsepower:

- High-Quality Brands:

- Injector Dynamics, DeatschWerks, and Bosch are trusted options.

Fuel Pump

A high-flow fuel pump provides the volume needed to meet your engine’s demands.

- Upgrading Options:

- In-tank pumps: Walbro 450 or DeatschWerks DW400 for street and track use.

- External pumps: Aeromotive A1000 for extreme builds.

- Dual Pump Systems:

- For builds exceeding 800 HP, dual fuel pumps ensure consistent flow.

Fuel Pressure Regulator (FPR)

A quality FPR maintains steady fuel pressure, which is vital for consistent performance.

- Adjustable FPRs:

- Allows precise tuning to match injector flow rates.

- Target pressure: ~43.5 PSI (3 bar) under normal conditions.

- Recommended Brands:

- Aeromotive, AEM, or Fuelab for durability and precision.

Fuel Lines and Filters

Upgraded fuel lines and filters ensure optimal flow and prevent contamination.

- Lines:

- Use braided stainless steel or PTFE-lined hoses for high-pressure durability.

- Recommended size: AN-8 or AN-10 for high-flow systems.

- Filters:

- Install a high-capacity inline filter (e.g., 10-micron) to trap debris.

Engine Management Systems (EMS)

An advanced EMS is essential for tuning and monitoring fuel delivery.

- Standalone ECUs:

- Offer precise control over fuel and ignition timing.

- Popular Choices: AEM Infinity, Haltech Elite, or Link G4X.

- Features to Look For:

- Wideband O2 sensor support for real-time air-fuel ratio monitoring.

- Data logging for analyzing engine performance.

Tuning for Drift Applications

Proper tuning maximizes performance and reliability.

- Air-Fuel Ratios (AFR):

- Target AFR for turbocharged engines:

- Idle and cruising: ~14.7:1.

- Wide-open throttle (WOT): ~11.5–12.5:1.

- Target AFR for turbocharged engines:

- Ignition Timing:

- Advance timing cautiously to enhance throttle response without risking detonation.

Common Mistakes to Avoid

- Undersized injectors that limit power potential.

- Ignoring fuel line upgrades, leading to flow restrictions.

- Improper fuel pump installation, resulting in inconsistent pressure.

Cooling and Lubrication Systems

Drifting places significant stress on an engine, generating excessive heat and demanding consistent lubrication. Upgrading cooling and lubrication systems ensures the reliability and performance of your 2JZ engine during prolonged drift sessions.

Radiator Upgrades

A high-performance radiator is essential for maintaining engine temperatures during high-stress conditions.

- Core Design:

- Opt for an aluminum radiator with dual or triple-core construction for improved heat dissipation.

- Brands to Consider:

- Mishimoto, Koyo, or CSF are reliable options.

- Coolant Mixture:

- Use a 70/30 mix of distilled water and coolant for maximum cooling efficiency.

- Consider adding a coolant additive (e.g., Red Line Water Wetter) to reduce temperatures further.

Oil Cooler Systems

An oil cooler prevents oil from breaking down under high temperatures, ensuring consistent lubrication.

- Air-to-Oil Coolers:

- Mounted in front of the radiator for optimal airflow.

- Thermostatic Sandwich Plates:

- Maintain ideal oil temperatures by bypassing the cooler during warm-up.

- Recommended Sizes:

- For drift-specific setups, a 19-row or larger oil cooler is ideal.

Upgraded Oil Pump

A high-flow oil pump ensures adequate lubrication at high RPMs.

- Key Features:

- Increased flow capacity to handle elevated power levels.

- Improved pressure stability under high loads.

- Popular Options:

- Powerhouse Racing (PHR) or OEM pumps with flow modifications.

Baffled Oil Pans

Preventing oil starvation during aggressive cornering is crucial for drifting.

- Benefits:

- Internal baffles reduce oil sloshing under lateral G-forces.

- Pickup design ensures consistent oil delivery.

- Recommended Brands:

- Moroso, Canton Racing, or custom pans designed specifically for the 2JZ.

Thermostat and Fans

Efficient cooling relies on precise temperature regulation and airflow.

- Low-Temperature Thermostats:

- Improves coolant flow and maintains lower operating temperatures.

- Example: TRD or Mishimoto thermostats.

- Electric Fans:

- Use dual electric fans with high CFM ratings.

- Ensure proper shrouding for maximum efficiency.

Intercooler Cooling Systems

Turbocharged setups benefit from enhanced intercooler cooling systems.

- Spray Bars:

- Water or CO2 spray bars cool the intercooler core during high-demand sessions.

- Air Ducting:

- Directs airflow to the intercooler for improved heat exchange.

Oil and Coolant Monitoring

Install gauges to track critical parameters in real-time.

- Oil Temperature and Pressure Gauges:

- Ensure oil temperatures stay within 200°F–240°F during operation.

- Coolant Temperature Gauges:

- Monitor for overheating; ideal operating range is 180°F–200°F.

Common Mistakes to Avoid

- Overlooking oil pan baffles, leading to oil starvation.

- Using undersized radiators, causing frequent overheating.

- Ignoring proper fan shrouding, reducing cooling efficiency.

Designing the Exhaust System for Maximum Performance

A well-designed exhaust system plays a crucial role in optimizing the 2JZ engine for drift applications. It enhances power output, reduces backpressure, and provides a distinctive sound that reflects the car’s performance.

Balancing Flow and Backpressure

The goal of a drift car exhaust system is to maximize exhaust gas flow without losing low-end torque.

- Pipe Diameter:

- 3-inch diameter: Suitable for builds up to 600 HP.

- 4-inch diameter: Ideal for high-power builds exceeding 800 HP.

- Avoid oversized piping on lower horsepower builds, as it can reduce responsiveness.

- Muffler Design:

- Straight-through mufflers minimize backpressure while maintaining an aggressive tone.

- Brands to Consider: HKS, MagnaFlow, or Borla.

Material Choices

The material of the exhaust system affects durability, weight, and performance.

- Stainless Steel:

- Offers excellent corrosion resistance and durability.

- Commonly used in high-performance exhausts.

- Titanium:

- Lightweight and heat-resistant, but expensive.

- Ideal for competitive drifting to reduce weight.

- Mild Steel:

- Affordable but prone to rust; suitable for budget builds.

Exhaust Manifolds

The manifold design directly impacts turbocharger efficiency and overall engine performance.

- Cast Iron Manifolds:

- Durable but may restrict flow at high power levels.

- Tuned Stainless Steel Manifolds:

- Maximizes flow and allows for quicker spool times.

- Recommended for turbocharged setups.

- Equal-Length vs. Log-Style Designs:

- Equal-length: Ensures uniform exhaust pulses for smoother performance.

- Log-style: Compact and suitable for lower horsepower builds.

Downpipe and Catalytic Converter

Upgrading the downpipe and catalytic converter enhances exhaust flow.

- Downpipe:

- Large-diameter downpipes improve turbo spool and reduce backpressure.

- Options: HKS, Tomei, or custom-fabricated designs.

- High-Flow Catalytic Converters:

- Balances emissions compliance with performance.

- Consider removing the cat for track-only builds (where legal).

Exhaust Tips

Exhaust tips are both functional and aesthetic.

- Single Exit:

- Lighter and simpler; popular for race-focused builds.

- Dual Exit:

- Offers a balanced look; commonly used for street-style drift cars.

Exhaust Sound Tuning

Sound is an integral aspect of a drift car’s character.

- Resonators:

- Reduces drone while maintaining an aggressive tone.

- Placement: Mid-pipe or after the catalytic converter.

- Variable Exhaust Systems:

- Allows drivers to switch between quiet and loud modes, offering flexibility for track and street use.

Heat Management

Proper heat management prevents damage to surrounding components.

- Heat Wraps and Shields:

- Use on downpipes and manifolds to reduce engine bay temperatures.

- Ceramic Coating:

- Provides additional heat resistance and improves exhaust gas velocity.

Common Mistakes to Avoid

- Oversizing pipes for low-power builds, resulting in reduced low-end torque.

- Using low-quality materials prone to rust or failure.

- Ignoring proper fitment, which can lead to leaks or rattling during operation.

Transmission, Clutch, and Differential Upgrades

For a drift car, the drivetrain must withstand high torque, provide precise control, and deliver power efficiently to the wheels. Upgrading the transmission, clutch, and differential is essential for reliability and optimal drift performance.

Transmission Options

The 2JZ engine pairs well with several transmission options depending on your power goals and budget.

- Stock Toyota Transmissions:

- R154 (5-Speed Manual):

- Reliable up to ~500 HP with minor upgrades.

- Affordable and widely available.

- V160 (6-Speed Manual):

- Designed for the Toyota Supra MKIV.

- Handles ~800 HP but is expensive and rare.

- R154 (5-Speed Manual):

- Aftermarket Transmissions:

- CD009 (Nissan 350Z):

- Budget-friendly with high durability (~700 HP).

- Requires adapter plates for compatibility.

- Tremec T56 Magnum:

- Handles 1,000+ HP, ideal for competitive builds.

- High cost but excellent performance and availability.

- CD009 (Nissan 350Z):

Clutch Upgrades

The clutch system must handle the increased torque and provide smooth engagement for precise drifting.

- Single-Plate Clutches:

- Best for street and light drift builds.

- Handles up to ~500 HP.

- Example: Exedy Hyper Single or ACT HD Clutch.

- Twin-Plate Clutches:

- For high-power applications (600+ HP).

- Provides better heat dissipation and smoother engagement.

- Brands to Consider: OS Giken, ACT, or Spec Clutch.

- Flywheel Selection:

- Lightweight flywheels improve throttle response.

- Chromoly flywheels offer durability for high-torque setups.

Differential Upgrades

The differential controls power delivery to the rear wheels, critical for initiating and sustaining drifts.

- Limited Slip Differential (LSD):

- Essential for even power distribution.

- Types:

- Clutch-Type LSD: Offers adjustable locking characteristics.

- Helical LSD (e.g., Torsen): Provides smooth engagement for street and drift use.

- Recommended Brands: Cusco, Kaaz, or OS Giken.

- Welded Differentials:

- Budget option for dedicated drift cars.

- Sacrifices versatility and may cause increased tire wear.

- Final Drive Ratios:

- Lower ratios (e.g., 4.1:1) improve acceleration for tighter tracks.

- Higher ratios (e.g., 3.5:1) are better for high-speed circuits.

Shifters and Linkages

- Short-Throw Shifters:

- Reduces shift time and improves precision.

- Example: Hurst, B&M, or TWM.

- Upgraded Linkages:

- Prevents slop and ensures consistent engagement.

Drivetrain Reinforcement

- Driveshaft Upgrades:

- Aluminum or carbon fiber driveshafts reduce weight and rotational mass.

- Strengthened steel driveshafts for durability in high-torque builds.

- Axle Reinforcements:

- Heavy-duty axles prevent breakage during aggressive drifting.

- Brands like Driveshaft Shop offer reliable options.

Common Mistakes to Avoid

- Using a clutch not rated for your power level, leading to premature wear.

- Ignoring differential upgrades, resulting in poor drift initiation.

- Neglecting drivetrain reinforcement, causing failures under stress.

ECU Tuning and Testing the Build

ECU tuning is the final step in optimizing your 2JZ engine for drift performance. Proper tuning ensures the engine runs efficiently, delivers consistent power, and remains reliable under high-stress conditions. Thorough testing validates your build and identifies areas for improvement.

The Role of ECU Tuning

An ECU (Engine Control Unit) manages the engine’s air-fuel ratio, ignition timing, and boost pressure. Upgrading to a standalone ECU allows precise control over these parameters for a drift-specific setup.

- Standalone ECUs:

- Examples: AEM Infinity, Haltech Elite, Link G4X.

- Benefits: Full control over tuning parameters and adaptability for future upgrades.

- Piggyback Systems:

- Modify signals from the factory ECU.

- Suitable for budget builds but less versatile than standalone ECUs.

Key Tuning Parameters

- Air-Fuel Ratio (AFR):

- Target AFR:

- Idle/Cruising: ~14.7:1 (stoichiometric).

- Wide Open Throttle (WOT): ~11.5–12.5:1 for turbocharged engines.

- Leaner mixtures improve efficiency but risk detonation at high boost.

- Target AFR:

- Ignition Timing:

- Advance timing for improved torque and responsiveness.

- Monitor for knock using sensors and adjust timing accordingly.

- Boost Pressure:

- Set conservative levels during initial tuning to ensure reliability.

- Gradually increase boost based on AFR stability and component capability.

Tools for ECU Tuning

- Wideband O2 Sensors:

- Essential for accurate AFR monitoring.

- Data Logging Software:

- Analyze engine performance metrics, including temperature, pressure, and timing.

- Knock Detection Devices:

- Identify detonation and prevent engine damage.

Dyno Testing

Dyno testing provides controlled conditions to fine-tune your engine and measure its performance.

- Steps in Dyno Tuning:

- Baseline run to establish current performance.

- Adjust AFR, timing, and boost incrementally.

- Conduct multiple runs to validate consistency.

- Outputs to Monitor:

- Torque and horsepower curves.

- Intake and exhaust temperatures.

- Peak boost pressure and RPM limits.

Real-World Testing

After dyno tuning, test your car in real-world conditions to simulate the stresses of drifting.

- Track Day Testing:

- Observe engine behavior under prolonged high RPMs and lateral forces.

- Monitor temperatures, oil pressure, and fuel delivery.

- Adjustments Post-Testing:

- Address overheating or fuel starvation issues.

- Refine throttle response for smoother drift initiation.

Safety Considerations

- Fail-Safe Features:

- Enable boost cut, rev limiter, and knock control for added protection.

- Regular Monitoring:

- Install gauges to track critical parameters, including AFR, oil pressure, and coolant temperature.

Common Mistakes to Avoid

- Overlooking knock control, leading to potential engine damage.

- Rushing through tuning without validating parameters under load.

- Neglecting real-world testing, which replicates drift-specific stresses.

Real-World Testing and Adjustments

After completing the build and tuning, real-world testing is crucial to evaluate the engine’s performance under drift conditions. Testing on a track helps you identify any weaknesses and fine-tune the setup for optimal results.

Preparing for Testing

- Initial Inspections:

- Double-check all fasteners, fluid levels, and connections.

- Verify that sensors, gauges, and monitoring equipment are functioning properly.

- Safety Measures:

- Ensure safety equipment (fire extinguisher, kill switch) is in place.

- Inspect tires, brakes, and suspension components for wear.

Track Testing for Drift Applications

Testing on a track simulates the stresses your engine and drivetrain will endure during drifting.

- Testing Objectives:

- Assess throttle response, torque delivery, and power consistency.

- Monitor engine behavior during sustained high RPMs and lateral G-forces.

- Critical Parameters to Monitor:

- Oil Temperature: Ensure it stays within 200°F–240°F.

- Coolant Temperature: Maintain a range of 180°F–200°F.

- Boost Levels: Confirm stability under load.

- Testing Steps:

- Warm-up laps to bring the engine and drivetrain to operating temperature.

- Gradually increase intensity, focusing on drift initiation and transitions.

- Analyze throttle input and tire grip to fine-tune power delivery.

Fine-Tuning Based on Results

Adjustments may be needed to address issues identified during testing.

- Engine Adjustments:

- Boost Levels: Increase or decrease boost for desired power output.

- Fuel Mapping: Refine air-fuel ratios to improve performance and reliability.

- Ignition Timing: Adjust for smoother throttle response or higher torque.

- Cooling and Lubrication:

- Add additional cooling (e.g., auxiliary oil coolers) if temperatures exceed safe limits.

- Ensure proper airflow to radiators and intercoolers.

- Suspension and Drivetrain:

- Fine-tune differential settings for better drift initiation.

- Adjust suspension alignment for improved cornering stability.

Common Issues and Solutions

- Overheating:

- Solution: Upgrade radiators, oil coolers, or fans.

- Oil Starvation:

- Solution: Install a baffled oil pan or accusump system.

- Boost Spikes:

- Solution: Re-tune wastegate settings or upgrade boost controllers.

- Throttle Lag:

- Solution: Optimize turbo sizing or fine-tune camshaft timing.

Feedback Loop

Testing and adjustments are iterative processes. Continue testing until your car delivers consistent performance on the track.

- Data Logging:

- Review logged data after each session to identify trends.

- Focus on patterns related to heat management, fuel delivery, and boost behavior.

- Driver Feedback:

- Incorporate feedback on throttle response, power delivery, and drift control.

- Adjust setup to match your driving style and track conditions.

Common Mistakes to Avoid

- Skipping the cooling-down process after intense sessions, risking component damage.

- Ignoring minor issues during testing, which can escalate into major problems.

- Focusing solely on power without addressing drivability and control.

Maintenance and Long-Term Care for Drift 2JZ Builds

Proper maintenance is essential to ensure the longevity and reliability of your 2JZ engine, especially when subjected to the high-stress conditions of drifting. Regular checks and preventive measures help avoid costly repairs and maximize performance.

Routine Maintenance Checklist

- Oil Changes:

- Frequency: Every 2-3 track sessions or 1,500–2,000 miles.

- Use high-quality synthetic oils (e.g., 10W-60 for high-temperature stability).

- Replace the oil filter with each change.

- Coolant System Maintenance:

- Flush the coolant system every season.

- Check hoses, clamps, and radiator for leaks or wear.

- Use distilled water and coolant additives to prevent scaling.

- Spark Plugs:

- Inspect and replace spark plugs every 3–4 sessions.

- Use plugs rated for your power level and boost (e.g., NGK Iridium).

- Air Filter:

- Clean or replace the air filter regularly to ensure optimal airflow.

- Use high-flow, washable filters for track use.

Post-Drift Session Inspections

- Visual Inspections:

- Check for leaks (oil, coolant, fuel).

- Inspect belts and pulleys for wear or damage.

- Bolts and Fasteners:

- Re-torque critical bolts, including those on the head, manifold, and suspension.

- Tires and Suspension:

- Check for uneven tire wear or alignment issues.

- Inspect bushings and joints for play or damage.

Preventive Maintenance

- Compression and Leak-Down Tests:

- Conduct every 6 months or after a high-intensity season.

- Identify early signs of piston ring or valve seal wear.

- Fuel System Cleaning:

- Clean injectors and inspect fuel lines for clogs or cracks.

- Replace the fuel filter annually for consistent flow.

- Turbocharger Health:

- Check for shaft play or oil leaks around the turbo.

- Ensure the wastegate and blow-off valve operate smoothly.

Upgrades for Reliability

- Heat Shields and Wraps:

- Protect nearby components from excessive heat generated by the turbo and exhaust.

- Auxiliary Oil Cooler:

- Add an additional cooler for extreme conditions or competitive drifting.

- Accusump Systems:

- Prevent oil starvation during aggressive cornering.

Seasonal Maintenance

- Engine Overhaul:

- For high-power builds, consider a complete teardown and inspection every 2–3 seasons.

- Replace bearings, seals, and gaskets as needed.

- Transmission and Differential:

- Flush and replace fluids annually.

- Inspect clutches, synchros, and LSD components for wear.

Storage Tips

- Long-Term Storage:

- Drain fuel or use a stabilizer to prevent degradation.

- Disconnect the battery and use a trickle charger.

- Cover the car to protect it from dust and moisture.

- Periodic Startups:

- Start the engine every few weeks to circulate oil and prevent seizing.

Common Mistakes to Avoid

- Neglecting oil changes, leading to premature wear.

- Overlooking small leaks, which can escalate into major failures.

- Using incorrect or low-quality fluids, impacting performance and durability.

Resources for Enthusiasts

Building and maintaining a high-performance 2JZ engine for drift applications requires continuous learning and collaboration with the drifting and tuning community. Leverage these resources to stay updated, improve your skills, and connect with fellow enthusiasts.

Online Communities and Forums

- Supra Forums:

- A treasure trove of knowledge about 2JZ engines, builds, and tuning tips.

- Community experts provide advice and troubleshoot issues.

- Website: www.supraforums.com

- DriftWorks Forum:

- Focused on drift-specific setups, including suspension and engine mods.

- Ideal for discussing track techniques and sharing build progress.

- Reddit Communities:

- r/Drifting: Insights into techniques, events, and car setups.

- r/Cars: Broader discussions about automotive topics, including 2JZ builds.

YouTube Channels

- HP Academy:

- Detailed tutorials on tuning, engine builds, and drift setups.

- Content tailored for beginners and advanced enthusiasts.

- Channel: HP Academy

- Mighty Car Mods:

- Entertaining and informative videos about project car builds.

- Features episodes on 2JZ swaps and turbo setups.

- The Boosted Boiz:

- Real-world builds and track tests, focusing on high-horsepower engines.

Recommended Books and Guides

- “Engine Management: Advanced Tuning” by Greg Banish

- Explains tuning strategies for modern engines, including standalone ECUs.

- “How to Build Max Performance Toyota 2JZ-GTE Engines” by Joseph Potak

- A must-read for anyone diving into 2JZ builds.

- Factory Service Manual (FSM):

- The official Toyota repair manual provides detailed specifications and procedures.

Tools and Software

- Tuning Software:

- AEM Tuner, Haltech ESP, or Link PC Link for standalone ECU tuning.

- Simulation Tools:

- Dyno simulation software like Virtual Dyno to analyze performance metrics.

- Data Loggers:

- Innovate Motorsports or Racepak for comprehensive performance tracking.

Events and Competitions

- Drift Competitions:

- Attend events like Formula Drift or D1GP to observe professional builds and techniques.

- Local drift events provide hands-on experience and networking opportunities.

- Car Meets:

- Join meetups dedicated to Toyota Supra or JDM car enthusiasts.

- Build connections with experts and learn from their setups.

Social Media Groups

- Facebook Groups:

- 2JZ Engine Builders: Tips and tricks from experienced builders.

- JDM Drift Enthusiasts: Connect with drift car owners globally.

- Instagram and TikTok:

- Follow influencers and builders who share their projects and techniques.

Tips for Staying Updated

- Google Alerts:

- Set alerts for terms like “2JZ engine builds” and “drift car tuning” to receive updates on new articles and videos.

- Newsletters:

- Subscribe to automotive blogs and forums for the latest trends.

- Podcasts:

- Listen to shows like “Hooniverse” or “CarCast” for industry insights.

Closing Note

This guide provides everything you need to build a competitive 2JZ drift engine. From foundational upgrades to advanced tuning strategies, you’re now equipped to dominate the drift circuit. Remember, the key to success lies in continuous learning, experimentation, and connecting with the community.

FAQ: Building a 2JZ Engine for Drift Cars

How Much Horsepower Can a 2JZ Engine Handle in a Drift Build?

- Stock Configuration:

The stock 2JZ-GTE engine can handle around 800–900 horsepower with proper tuning and a high-quality fuel system. However, pushing the limits consistently may shorten engine life. - Upgraded Configuration:

With forged internals, upgraded fuel and cooling systems, and a reliable turbo setup, the 2JZ can handle well over 1,200 horsepower. For most drift applications, a target of 500–700 HP is ideal for balancing power and control.

What Turbocharger is Best for a Drift-Specific 2JZ Engine?

- Single Turbo Setup:

A Garrett GTX3076R is a popular choice for drift builds due to its balance of power and responsiveness. It offers excellent spool times while delivering sufficient airflow for up to 700 HP. - Twin-Turbo Setup:

While more complex, a twin-turbo setup like a sequential system can improve low-end response for technical tracks. - Key Considerations:

Prioritize quick spool times for responsive throttle control, which is crucial for drift transitions and sustained slides.

What Are the Most Common Problems with 2JZ Drift Builds?

- Overheating Issues:

Drifting generates excessive heat, leading to potential overheating. This can be mitigated with upgraded radiators, oil coolers, and efficient fans. - Oil Starvation:

Aggressive cornering causes oil sloshing, which may lead to starvation. Installing a baffled oil pan or an accusump system prevents this issue. - Boost Spikes:

Poor wastegate or boost controller setups can cause inconsistent boost levels, risking engine damage. High-quality components and proper tuning address this problem. - Drivetrain Stress:

The high torque of a tuned 2JZ can strain the transmission and differential. Reinforcing these components is crucial for reliability.

How Much Does It Cost to Build a Drift-Ready 2JZ Engine?

- Budget Build:

- Cost: $10,000–$15,000.

- Includes basic upgrades like forged pistons, a single turbo setup, and an aftermarket ECU.

- Mid-Tier Build:

- Cost: $20,000–$30,000.

- Adds advanced components like a high-flow fuel system, performance cams, and precision tuning.

- High-End Build:

- Cost: $40,000–$50,000+.

- Includes extreme upgrades for competitive drifting, such as a custom twin-turbo setup, billet internals, and race-spec drivetrain components.

Is a 2JZ-GTE Better Than a 2JZ-GE for Drifting?

- 2JZ-GTE (Twin Turbocharged):

- Pros: Factory turbocharging, stronger internal components, and higher power potential.

- Cons: More expensive and complex to maintain.

- 2JZ-GE (Naturally Aspirated):

- Pros: Affordable and easier to source. A great foundation for custom turbo setups.

- Cons: Requires significant upgrades (e.g., turbocharging, forged internals) to match the performance of the GTE.

- Conclusion: The 2JZ-GTE is the better choice for those seeking high performance with less modification. However, the 2JZ-GE can be a budget-friendly option for DIY enthusiasts willing to invest in upgrades.