The 2JZ-GTE engine, celebrated for its power and reliability, holds a special place in the hearts of car enthusiasts. Maintaining this iconic engine requires regular checks to ensure it runs smoothly and efficiently. Basic engine checks not only improve performance but also extend the lifespan of the engine.

In this article, we will explore the importance of basic engine checks, identify key areas that need regular inspection, and provide detailed procedures for each check. By following these guidelines, you can ensure your 2JZ-GTE engine continues to deliver optimal performance.

Understanding the Importance of Basic Engine Checks

Regular engine checks are essential for identifying potential issues before they become serious problems. These checks help maintain engine efficiency, improve fuel economy, and ensure the overall reliability of your vehicle.

Benefits:

- Improved Fuel Efficiency: Keeping the engine in good condition ensures it operates at peak efficiency, saving fuel.

- Reduced Wear and Tear: Regular maintenance minimizes wear on engine components, prolonging their lifespan.

- Early Problem Detection: Routine checks can identify issues early, preventing costly repairs and breakdowns.

Key Engine Checks for the 2JZ-GTE

Oil Level and Quality:

- How to Check: Park the vehicle on level ground and wait for the engine to cool. Remove the dipstick, wipe it clean, reinsert it, and then check the oil level. The oil should be between the minimum and maximum marks. Inspect the oil’s color and consistency; it should be amber and smooth.

- Importance: Oil lubricates engine components, reducing friction and wear. Regular oil changes prevent sludge buildup and maintain engine health.

Coolant Level and Condition:

- How to Check: With the engine cool, check the coolant level in the radiator and overflow tank. The coolant should be between the minimum and maximum marks. Inspect the coolant’s color; it should be bright green, red, or yellow, depending on the type, and free of contaminants.

- Importance: Coolant prevents the engine from overheating and freezing, maintaining optimal operating temperatures and protecting against corrosion.

Air Filter Condition:

- How to Check: Locate the air filter housing, remove the cover, and take out the air filter. Inspect it for dirt and debris. Hold it up to the light; if you can’t see light through it, it needs to be replaced.

- Importance: A clean air filter ensures a proper air-fuel mixture, improving combustion efficiency and engine performance.

Spark Plugs:

- How to Check: Remove the spark plugs and inspect them for signs of wear, carbon buildup, or damage. Check the gap using a feeler gauge and adjust if necessary.

- Importance: Spark plugs ignite the air-fuel mixture, and maintaining them ensures smooth engine operation and fuel efficiency.

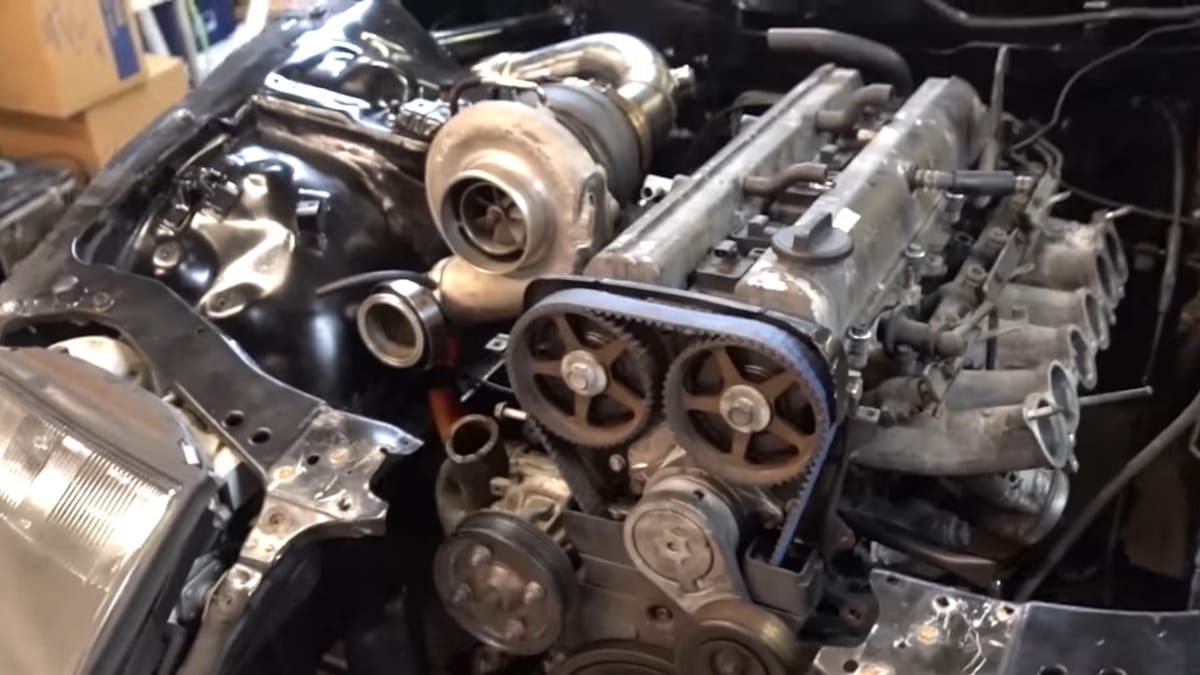

Belt and Hose Inspections:

- How to Check: Inspect the drive belts and hoses for signs of wear, cracks, or leaks. Check for proper tension and alignment.

- Importance: Belts and hoses are crucial for the operation of various engine components. Timely replacements prevent breakdowns and ensure smooth engine operation.

Detailed Procedures for Each Check

Oil Level and Quality Check:

- Preparation: Park the car on a level surface and turn off the engine. Allow it to cool.

- Checking the Oil Level:

- Open the hood and locate the dipstick.

- Pull out the dipstick, wipe it clean, reinsert it fully, then pull it out again to check the oil level.

- Ensure the oil level is between the minimum and maximum marks.

- Inspecting Oil Quality:

- Check the oil’s color and consistency. It should be amber and smooth. If it’s dark or gritty, it’s time for an oil change.

- Changing the Oil:

- Drain the old oil by removing the drain plug, replace the oil filter, and refill with the recommended oil type and amount.

Coolant Level and Condition Check:

- Preparation: Ensure the engine is cool before starting.

- Checking Coolant Levels:

- Open the radiator cap and check the coolant level. It should be near the top of the radiator.

- Check the overflow tank and ensure the coolant level is between the minimum and maximum marks.

- Inspecting Coolant Quality:

- Check the color of the coolant. It should be bright and free of contaminants. If it’s rusty or cloudy, consider flushing and replacing the coolant.

- Topping Up Coolant:

- If the level is low, add a 50/50 mix of coolant and distilled water to the radiator and overflow tank.

Air Filter Inspection:

- Locating the Air Filter: Locate the air filter housing under the hood.

- Removing the Air Filter:

- Open the housing and remove the air filter.

- Inspect the filter for dirt and debris. Hold it up to the light; if light doesn’t pass through, it’s time to replace it.

- Replacing the Air Filter:

- Insert a new air filter into the housing and secure the cover.

Spark Plug Inspection:

- Preparation: Ensure the engine is cool before starting.

- Removing Spark Plugs:

- Use a spark plug socket to remove the spark plugs.

- Inspect each spark plug for wear, carbon buildup, or damage.

- Checking Spark Plug Gap:

- Use a feeler gauge to measure the gap between the electrode and the ground strap. Adjust if necessary.

- Replacing Spark Plugs:

- If the spark plugs are worn or damaged, replace them with new ones of the correct specification.

Belt and Hose Inspection:

- Inspecting Belts:

- Check drive belts for signs of wear, cracks, or fraying.

- Ensure belts are properly tensioned and aligned.

- Inspecting Hoses:

- Check hoses for signs of leaks, cracks, or soft spots.

- Ensure hose clamps are tight and secure.

- Replacing Belts and Hoses:

- Replace any worn or damaged belts and hoses to prevent breakdowns.

Preventive Maintenance Tips

Regular Inspection Schedule:

- Develop a schedule for regular engine checks. For example, check oil levels and coolant condition monthly, and inspect air filters, spark plugs, belts, and hoses every six months.

Using Quality Parts:

- Use high-quality replacement parts to ensure longevity and reliability. Cheap parts can fail prematurely and cause additional issues.

Keeping Records:

- Keep a log of all maintenance activities, including dates, parts replaced, and any issues found. This helps track the health of your engine and plan future maintenance.

Conclusion

Regular engine checks are essential for maintaining the performance and longevity of the 2JZ-GTE engine. By performing these basic checks, you can ensure that your engine remains in top condition, delivering the power and reliability that the 2JZ-GTE is known for.

Implement a regular engine check routine to catch potential issues early and maintain optimal performance. If you encounter any problems or need assistance, seek professional help to ensure your engine is properly maintained.

Frequently Asked Questions (FAQ)

Why are regular engine checks important?

Regular engine checks help identify potential issues early, maintain fuel efficiency, and ensure the engine’s longevity.

How often should I perform basic engine checks?

Perform basic engine checks monthly for oil and coolant levels, and every six months for air filters, spark plugs, belts, and hoses.

What tools do I need for basic engine checks?

Basic tools include a dipstick, a multimeter, a spark plug socket, a feeler gauge, and a funnel for topping up fluids.

Can I perform these checks myself, or should I go to a professional?

You can perform many of these checks yourself with basic tools and knowledge. However, for more complex issues or if you’re unsure, seek professional help.

What are the signs that my engine needs maintenance?

Signs include unusual noises, reduced fuel efficiency, poor acceleration, rough idling, and visible leaks or damage.