When it comes to keeping your 2JZ engine humming smoothly, the turbo manifold and wastegate are like the unsung heroes behind the scenes. These parts handle intense heat and pressure day in and day out, so they need a little TLC to keep everything running at its best. Ignoring them? That’s a shortcut to headaches—think unexpected power drops or worse, costly repairs. But here’s the good news: with a bit of know-how and regular checkups, you can spot problems early and keep your engine firing on all cylinders.

Let’s talk cracks first. Tiny fractures in the turbo manifold might seem harmless, but they can quickly turn into major leaks that sap your boost pressure. Imagine trying to blow up a balloon with a tiny hole—it just won’t hold air, right? The same principle applies here. And the wastegate? If it sticks or malfunctions, your boost levels can swing wildly, making your ride unpredictable and less fun. It’s like having a car that suddenly loses its punch when you step on the gas.

Checking these parts isn’t as scary as it sounds. You don’t need a fancy garage or a mechanic on speed dial. A careful visual inspection, a simple boost leak test, and knowing what to listen for can save you from bigger headaches. Plus, tightening bolts to the right specs and keeping an eye on gaskets and flanges ensures everything stays sealed tight. It’s like giving your turbo system a well-deserved spa day—clean, secure, and ready to roar.

In this article, we’ll break down the essentials: how to spot cracks, detect boost leaks, recognize wastegate issues, and when it might be time to upgrade to stronger, high-performance parts. Whether you’re a weekend warrior or a daily driver, these tips will help you keep your 2JZ turbo system in peak shape. Ready to dive in? Let’s get your engine back to that sweet spot of power and reliability.

Why Regular Turbo Manifold and Wastegate Inspections are Vital

Think of your 2JZ turbo manifold and wastegate as the heart and lungs of your turbo system. They work tirelessly, pushing and controlling the flow of exhaust gases to keep your engine humming at its best. But just like any hardworking part, they need a little TLC now and then. Skipping regular inspections is like ignoring a slow leak in a tire—you might not notice the problem until it’s too late, and the damage is costly.

Regularly checking your turbo manifold and wastegate isn’t just about preventing breakdowns; it’s about maintaining smooth, consistent boost pressure. When these components start to crack, warp, or leak, the turbo can’t perform efficiently. You’ll feel it in sluggish acceleration, uneven power delivery, or worse, sudden drops in boost that leave you stranded or frustrated on the road.

Here’s the kicker: small issues often snowball into big problems. A tiny crack in the manifold can let exhaust gases escape, reducing turbo spool and causing the engine to run hotter. A sticking wastegate can throw off boost control, leading to either underboost or dangerous overboost situations. Both scenarios can damage your engine over time.

By making inspections a regular habit, you catch these issues early—before they spiral out of control. It’s like catching a cold in the first day rather than waiting for full-blown flu. Plus, routine checks save you money and time down the road by avoiding emergency repairs and unexpected breakdowns.

So, what should you look out for during these inspections? Pay attention to any visible cracks or corrosion on the manifold, listen for unusual noises from the wastegate, and watch for any signs of boost leaks. If you’re serious about keeping your 2JZ running strong, these simple steps can make a world of difference.

In short, regular inspections are your best defense. They keep your turbo system tight, your engine happy, and your drive smooth. Don’t wait for a problem to announce itself loudly—stay ahead, stay sharp, and keep that boost steady.

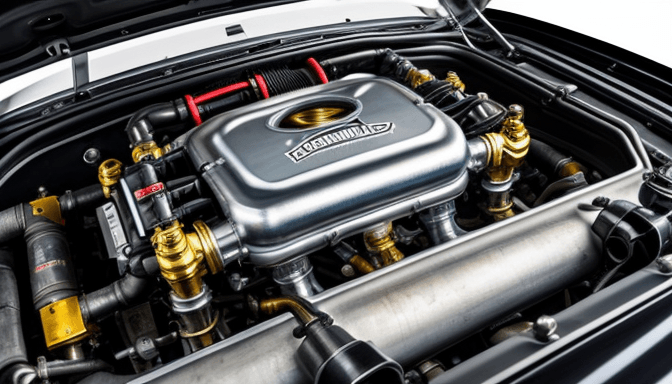

How to Check for Cracks and Damage in the 2JZ Turbo Manifold

Spotting cracks or damage in your 2JZ turbo manifold might seem tricky at first glance, but with a little know-how, it becomes a straightforward task. Think of your manifold as the heart of your turbo setup—it channels hot exhaust gases to spin the turbo, so any crack is like a leak in your heart’s arteries. It weakens performance and can cause headaches down the road. The first step? Get your hands dirty and your eyes sharp.

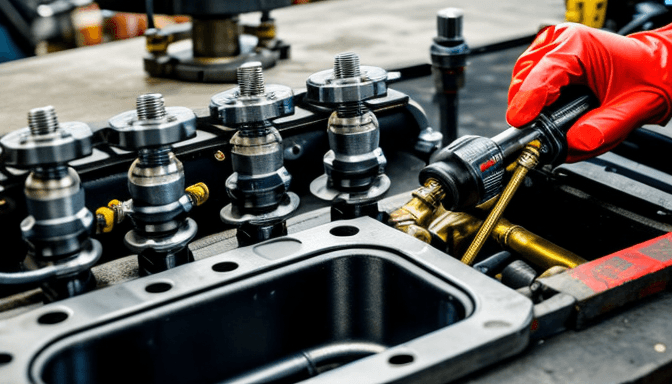

Start with a thorough visual inspection. Look closely at the manifold’s surface, especially around the welds and bends where stress tends to build up. Cracks often begin as tiny hairlines, so don’t rush. Use a bright flashlight and maybe even a magnifying glass if you have one handy. You’re hunting for any irregular lines or discoloration—these could be signs of heat damage or metal fatigue. Don’t forget to check the inside too, if you can safely access it, as internal cracks can be just as harmful.

Next, run your fingers along the manifold’s surface. Sometimes, you can feel a crack or rough spot that your eyes might miss. If the metal feels uneven or there’s a slight gap, that’s a red flag. Also, gently tap the manifold with a small metal tool; a dull or different sound can hint at a hidden crack or weak spot. This simple trick can save you from costly surprises later.

Corrosion is another silent enemy. The 2JZ manifold handles extreme temperatures, and over time, rust can creep in, especially if moisture or road salt gets involved. Rust weakens the metal and can lead to cracks if left unchecked. Look for flaky, reddish patches or bubbling paint. If you spot these, it’s time to consider repairs or replacement.

Warping is less obvious but just as damaging. A warped manifold won’t seal properly, leading to exhaust leaks and lost boost pressure. To check for warping, you’ll need a straight edge and feeler gauge. Place the straight edge along the flange or flat surfaces; if you can slide the feeler gauge under it easily, your manifold might be bent. This subtle deformation can throw off your turbo’s efficiency.

Finally, if you want to be thorough, consider a dye penetrant test. This method uses a special liquid that seeps into cracks and becomes visible under UV light. It’s a favorite among pros because it reveals even the smallest fractures invisible to the naked eye. While it might sound fancy, kits are affordable and easy to use at home.

Remember, catching cracks and damage early isn’t just about fixing problems—it’s about keeping your 2JZ running smooth and strong. Treat your turbo manifold like a prized piece of gear, and it’ll reward you with consistent power and longevity. After all, a well-maintained manifold means your engine breathes easier and performs better. So, don’t wait for a blowout—check regularly and keep your boost game tight.

Common Signs of a Failing or Sticking Wastegate

Ever felt like your car just isn’t hitting the boost it used to? That’s often the first hint something’s off with your wastegate. This little valve plays a huge role in controlling boost pressure, and when it starts sticking or failing, the whole turbo system feels it. Imagine trying to breathe through a straw that’s partly blocked—your engine’s boost behaves the same way. You might notice the boost pressure jumping all over the place instead of staying steady. One moment you’re getting a nice surge, the next, it feels like the turbo’s taking a nap.

Another telltale sign is poor acceleration. You press the gas, expecting that thrilling turbo kick, but instead, it drags. It’s frustrating, right? This happens because the wastegate isn’t opening or closing at the right times, messing with how much exhaust gas spins the turbine. And don’t ignore strange noises—sometimes a failing wastegate makes a fluttering or rattling sound that’s hard to miss if you’re paying attention. It’s like your engine’s way of waving a red flag.

Sometimes, the wastegate can get stuck open, leading to a constant low boost situation. Your car might feel sluggish, and no matter how much you floor it, the power just doesn’t come. On the flip side, if it sticks closed, you risk overboosting, which can damage your engine in the long run. It’s a delicate balance, and the wastegate is the gatekeeper. When it’s not doing its job, your engine’s health and performance take a hit.

Here’s a quick rundown of what to watch for:

- Fluctuating or inconsistent boost pressure

- Delayed or weak acceleration response

- Unusual fluttering or rattling sounds near the turbo

- Engine warning lights or check engine codes related to boost control

Ignoring these signs is like ignoring a small leak in a dam—it might seem minor at first, but it can lead to bigger problems down the road. So, if your ride feels off or the boost isn’t steady, take a closer look at the wastegate. It’s often the unsung hero that keeps your turbo running smooth and your engine happy.

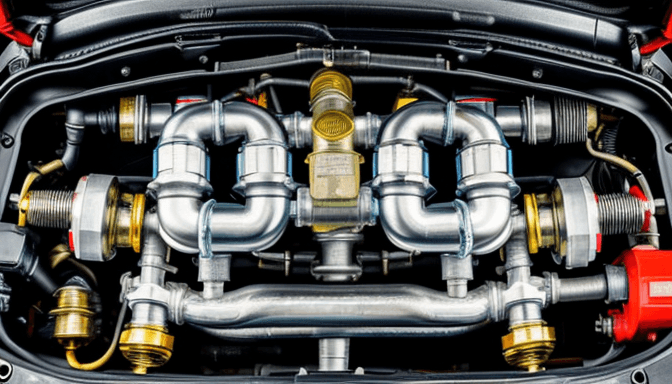

How to Perform a Boost Leak Test on a 2JZ System

So, you suspect your 2JZ isn’t running as tight as it should? Maybe the boost feels weak or inconsistent. It’s time to check for boost leaks. Don’t worry—it’s not rocket science, but it does require a bit of patience and the right approach. Think of your turbo system like a balloon. If there’s a hole, no matter how small, the balloon won’t hold air. Same goes for your turbo manifold and piping. A tiny leak can cause a big headache.

First, you’ll need a pressure source to simulate boost pressure without firing up the engine. Many pros use a hand-held pressure tester or a smoke machine. The smoke machine is especially handy because it visually shows where leaks escape. Imagine seeing little wisps of smoke sneaking out—that’s your leak’s signature. If you don’t have a smoke machine, a simple pressure gauge attached to the intake piping can work. You pressurize the system to about 10-15 psi, then listen carefully for hissing sounds.

Here’s a quick rundown of what to do: disconnect the intake piping after the turbo, seal the system, and slowly apply pressure. Walk around the engine bay, paying close attention to common weak points like hose clamps, silicone couplers, and the turbo manifold flange. Don’t forget to check the wastegate actuator and any vacuum lines connected to it. These areas often hide leaks that cause boost drops.

Sometimes, leaks are sneaky and don’t make obvious noises. That’s when the smoke test really shines. The smoke fills the system, and any cracks or loose fittings will let it escape. It’s like sending a smoke signal to pinpoint trouble spots. Once you find a leak, mark it, then tighten clamps or replace gaskets as needed.

Remember, a well-sealed system means your turbo can work efficiently, giving you the power and responsiveness you crave. Skipping this simple test can lead to wasted time chasing phantom problems. Trust me, I’ve been there—hours lost wondering why the boost is off, only to find a loose clamp was the culprit all along.

In short, regular boost leak testing is an easy step that saves you money and frustration. It keeps your 2JZ humming smoothly and your ride feeling sharp. So grab your tools, get hands-on, and don’t let a tiny leak steal your thunder.

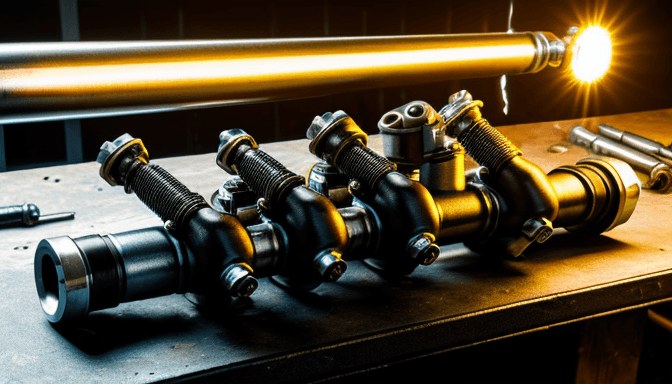

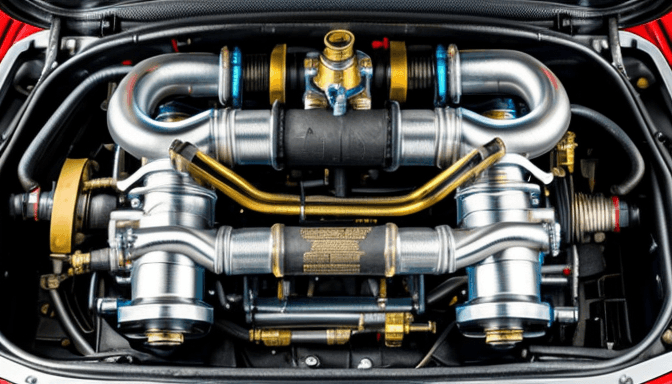

Inspecting Gaskets and Flanges for Leaks and Warping

When it comes to keeping your 2JZ turbo system running smooth, gaskets and flanges are often the unsung heroes. They might seem like small parts, but these components play a huge role in sealing your turbo setup and preventing boost leaks. Over time, heat cycles and constant pressure can cause gaskets to wear out or flanges to warp, leading to tiny gaps that sneakily rob your engine of power. Imagine trying to blow up a balloon with a hole in it — frustrating, right? That’s exactly what a leak does to your boost pressure.

Checking these parts isn’t just about a quick glance. You’ll want to remove the turbo manifold and give the gaskets a thorough look. Look for cracks, brittleness, or any signs of compression damage. A gasket that’s lost its flexibility won’t seal properly, no matter how tight you bolt things down. Flanges, on the other hand, need a careful eye for warping. Even a slight bend can cause uneven contact surfaces, creating gaps that let boost escape.

Here’s a simple way to spot warping: place a straight edge or ruler across the flange surface. If you see gaps between the ruler and the metal, that’s a red flag. Warped flanges often mean it’s time to replace or carefully machine them back to flatness. Don’t skip this step — a warped flange can lead to persistent leaks that are hard to diagnose.

One trick I learned the hard way is to always replace gaskets whenever you remove the turbo manifold. Reusing old gaskets might save a few bucks now, but it can cause headaches later with slow leaks and fluctuating boost. It’s like trying to patch a leaky tire with duct tape — a temporary fix at best.

And don’t forget the bolts! Uneven or loose bolts can cause flanges to shift, breaking the seal. Using the right torque specs and tightening bolts in the correct sequence ensures an even clamp, keeping your gaskets happy and your boost sealed tight.

In short, never underestimate the small stuff when it comes to your turbo setup. Gaskets and flanges might not be flashy, but they’re the foundation of a leak-free system. Keep them in check, and your 2JZ will thank you with consistent power and reliability.

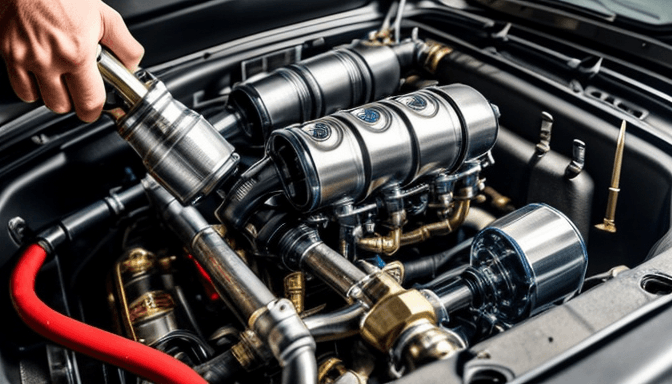

Best Practices for Securing Turbo and Manifold Bolts

When it comes to the turbo and manifold bolts on your 2JZ, the details matter more than you might think. These bolts aren’t just metal fasteners; they’re the guardians of your engine’s performance. If they’re too loose, you risk leaks and damage. Too tight, and you might warp the manifold or strip threads. Finding that sweet spot is key.

First off, always use a quality torque wrench. It’s tempting to just tighten bolts by feel, but trust me, that’s a shortcut to trouble. Each bolt has a recommended torque setting, often found in your vehicle’s service manual. For the 2JZ turbo manifold, this usually falls in the range of 18 to 22 ft-lbs, but double-checking never hurts. Tighten bolts in a proper sequence—usually starting from the center and moving outward in a crisscross pattern. This ensures even pressure and avoids warping the manifold.

Another tip? Don’t skip on thread locker or anti-seize compounds where appropriate. Thread locker keeps bolts from vibrating loose under the intense heat and vibration of your engine bay. Anti-seize, on the other hand, helps prevent bolts from galling or seizing up, especially on exhaust components exposed to extreme temperatures. Just remember, these compounds can affect torque readings, so adjust accordingly.

Heat cycles are brutal on turbo components. Over time, bolts can loosen as metal expands and contracts. That’s why rechecking bolt tightness after a few heat cycles or a few hundred miles is smart. It’s like giving your engine a quick health check without the hassle. Don’t wait for a leak or a rattle to remind you.

Here’s a quick rundown of what to keep in mind:

- Use a calibrated torque wrench.

- Follow the manufacturer’s torque specs.

- Tighten bolts in the correct sequence.

- Apply thread locker or anti-seize as needed.

- Re-torque bolts after initial heat cycles.

Think of securing these bolts like tuning a guitar. Too loose, and the strings buzz; too tight, and they snap. With the right balance, your turbo system will sing smoothly and deliver the boost you crave without hiccups. Taking the time to do this right isn’t just maintenance—it’s peace of mind for every mile you drive.

How Wastegate Problems Affect Boost Control and Engine Health

Ever felt your car’s boost pressure acting like a rollercoaster? That’s often a sign your wastegate is struggling. The wastegate’s job is simple but critical: it controls how much exhaust gas hits the turbo, which in turn regulates boost pressure. When it falters, things can spiral quickly. Imagine trying to ride a bike with a bent wheel—it wobbles, loses speed, and risks a crash. That’s what a faulty wastegate does to your engine’s performance.

When the wastegate sticks open, your turbo can’t build enough boost. The engine feels sluggish, and acceleration suffers. On the flip side, if the wastegate sticks closed, boost pressure can spike dangerously high. This isn’t just about losing power; it’s about risking serious engine damage. Overboost can lead to blown head gaskets, melted pistons, or worse. It’s like letting too much air into a balloon—it bursts.

Noise is another clue. A rattling or fluttering sound might mean the wastegate actuator is failing or the valve isn’t sealing properly. This subtle hint shouldn’t be ignored because it often precedes bigger issues. Plus, inconsistent boost makes tuning a nightmare. Your engine’s fuel and timing maps rely on steady boost levels, and a misbehaving wastegate throws everything off balance.

Here’s a quick breakdown of what wastegate problems can cause:

- Fluctuating boost pressure leading to unpredictable power delivery

- Poor fuel efficiency due to improper air-fuel mixtures

- Increased engine heat, raising the risk of component failure

- Potential turbo damage from excessive pressure

Think of the wastegate as the gatekeeper of your turbo’s power. If it’s not doing its job, the whole system suffers. Regular checks are vital. You don’t want to wait until your engine throws a fit on the highway or during a spirited drive. Catching wastegate issues early means smoother rides and a healthier engine in the long run. After all, keeping your boost in check isn’t just about speed—it’s about keeping your engine alive and kicking.

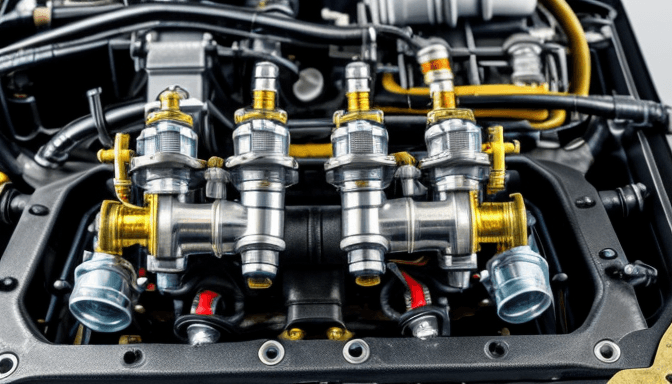

When to Upgrade to a High-Performance Manifold or Wastegate

So, you’ve been pushing your 2JZ engine hard, and the stock turbo manifold or wastegate just isn’t cutting it anymore. How do you know when it’s time to step up your game? Well, upgrading isn’t just about bragging rights or chasing bigger numbers on the dyno—it’s about making sure your engine breathes right and stays reliable under pressure.

First off, if you’re noticing inconsistent boost levels or your turbo feels sluggish, that’s a red flag. Stock manifolds and wastegates are designed for everyday driving, not the kind of abuse a spirited driver or tuner might throw at them. When boost leaks start creeping in or your wastegate sticks, it’s like trying to run a marathon with a clogged airway—performance tanks, and stress on engine parts skyrockets.

Another clear sign is if you’re chasing more power. Say you’ve upgraded your turbo or added a bigger intercooler, but your stock manifold chokes the airflow or your wastegate can’t handle the increased boost pressure. In these cases, a high-performance manifold made from thicker, heat-resistant materials can handle the extra heat and stress without cracking or warping. Similarly, a beefier wastegate offers better control over boost pressure, keeping your engine safe from spikes that could cause serious damage.

Think of it like upgrading from a garden hose to a firehose. The garden hose (stock manifold/wastegate) works fine for watering plants, but it struggles when you need to put out a fire (high boost demands). The firehose (high-performance parts) is built to handle that pressure without bursting or faltering.

Also, if you’re into track days or spirited driving, the repeated heat cycles and vibration can wear down stock components faster. High-performance parts are designed to withstand this abuse, offering better durability and peace of mind. You might even notice improved throttle response and smoother boost delivery, which makes driving more enjoyable.

In short, consider upgrading when:

- Your current setup shows signs of wear or leaks.

- You’re increasing power beyond stock limits.

- You want improved reliability for aggressive driving.

- You’re experiencing boost control issues with the stock wastegate.

Upgrading isn’t just a luxury—it’s a smart move to protect your engine and keep your 2JZ running strong. After all, pushing your car to the limit deserves parts that can keep up.

Frequently Asked Questions

- Why is it important to regularly inspect the 2JZ turbo manifold and wastegate?Think of your turbo manifold and wastegate as the heart and lungs of your turbo system. Regular inspections catch tiny cracks or leaks before they explode into costly repairs. Plus, keeping everything tight ensures your boost pressure stays consistent, which means your engine runs smoother and stronger. Don’t wait for a performance drop to remind you—stay ahead by checking often!

- How can I tell if my 2JZ turbo manifold has cracks or damage?Visual inspection is your first line of defense. Look closely for hairline cracks, corrosion spots, or any warping on the manifold surface. A flashlight and a mirror can help spot hidden trouble. If you notice soot marks or hear unusual hissing noises, those are red flags pointing to possible cracks or leaks that need immediate attention.

- What are the common signs that my wastegate might be failing or sticking?Is your boost pressure acting like a rollercoaster? Fluctuating or inconsistent boost, sluggish acceleration, or strange noises like rattling or fluttering often mean the wastegate is misbehaving. A sticking wastegate can choke your turbo’s power or cause dangerous overboost situations, so catching these symptoms early can save your engine from serious damage.

- How do I perform a boost leak test on my 2JZ turbo system?Testing for boost leaks is easier than you think! You can use a pressure gauge to pressurize the system and listen for leaks, or better yet, a smoke machine to visually spot escaping air. This method highlights those sneaky leaks around gaskets, flanges, or pipes that silently rob your turbo’s efficiency.

- Why should I inspect gaskets and flanges for leaks and warping?Gaskets and flanges are the seals that keep your turbo system airtight. When they warp or crack, they become like open doors for boost to escape. This not only reduces power but can also cause uneven pressure that stresses other components. Regular checks and replacements keep your turbo system sealed tight and performing at its peak.

- What’s the best practice for securing turbo and manifold bolts?Bolts might seem simple, but they’re critical! Use the manufacturer’s recommended torque settings and follow the tightening sequence like a recipe for success. This prevents bolts from loosening due to heat cycles and vibrations, which could otherwise cause leaks or damage. Think of it as giving your turbo system a solid handshake that won’t let go.

- How do wastegate problems affect boost control and engine health?A malfunctioning wastegate is like a faulty thermostat—it throws off the whole system. If it sticks closed, you risk dangerous overboost that can fry your engine. If it sticks open, you lose power and efficiency. Either way, your engine’s health and turbo control take a hit, so fixing wastegate issues quickly is key to keeping your ride reliable and powerful.

- When should I consider upgrading to a high-performance manifold or wastegate?If you’re chasing more power or pushing your 2JZ beyond stock limits, upgrading is a smart move. High-performance manifolds and wastegates handle extra boost and heat better, offering improved reliability and faster turbo response. It’s like swapping out a family sedan’s brakes for race-grade ones—better parts mean you can push harder without breaking down.